Abstract

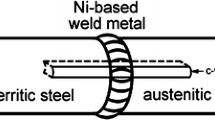

Dissimilar metal weld failures between low alloy Cr-Mo ferritic steels and austenitic stainless steels made with Ni-base filler metals are typically observed along the fusion line. Such DMW failures often exhibit the onset of damage well before their expected service life. Failure is typically associated with a carbon-depleted region in the ferritic steel and formation of creep voids along a row of so-called Type I carbides. More recently, the formation of Type I carbides adjacent to a carbide-free ferrite band has also been observed in DMWs where the ferritic steel was a 9 pct Cr creep strength-enhanced ferritic steel. However, it has not been completely clarified whether these microstructural features formed during welding, post-weld heat treatment or service. In this study, single pass bead-on-plate welds were prepared on a Grade 91 steel substrate using commonly specified Ni-base weld metals; ENiCrCoMo-1, ENiCrMo-3, ENiCrFe-3, ENiCrFe-2 and EPRI P87 (ENiFeCr-4) and were characterized in the as-welded, post-weld heat treatment (PWHT) and aged conditions. The evolution of the ferrite band was found to form by a diffusion-controlled process and was observed after PWHT and aging associated with regions exhibiting steep concentration gradients in the partially mixed zone (PMZ). In this study, steep concentration gradients were observed along the toe of the weld whereas relatively shallow gradients were observed at the weld bottom-center, resulting in a discontinuous ferrite band along the fusion line during PWHT and aging. The variation in chemical gradients in the PMZ corresponded to different chemical potential gradients, which lead to differences in carbon diffusion during high-temperature PWHT and aging. The results of this study provide insight into potential solutions for minimizing the risk of failure in future applications.

Similar content being viewed by others

References

S.A. David, J.A. Siefert, J.N. Dupont, and J.P. Shingledecker: Sci. Technol. Weld. Join., 2015, vol. 20, pp. 532–52.

S.A. David, J.A. Siefert, and Z. Feng: Sci. Technol. Weld. Join., 2013, vol. 18, pp. 631–51.

B. Dooley and P.S. Chang: Powerpl. Chem., 2000, vol. 4, pp. 197–203.

J.N. DuPont: Int. Mater. Rev., 2012, vol. 57, pp. 208–34.

C. SUDHA, V.T. PAUL, A.L.E. TERRANCE, S. SAROJA, and M. VIJAYALAKSHMI: Weld. J., 2006, vol. 85, pp. 71s-80s.

J. William, G. Clark, and G. Investigating: 2015.

J. Siefert and J. Parker: Program on Technology Innovation: Guidelines and Specifications for High-Reliability Fossil Power Plants—Best Practice Guideline for Manufacturing and Construction of Grade 91 Steel to Austenitic Stainless Steel Dissimilar Metal Welds, 2017.

J.D. Parker and G.C. Stratford: Sci. Technol. Weld. Join., 1999, vol. 4, pp. 29–39.

J.D. Parker and G.C. Stratford: Mater. Sci. Eng. A, 2001, vol. 299, pp. 164–73.

J.D. Parker and G.C. Stratford: J. Mater. Sci., 2000, vol. 35, pp. 4099–107.

D.I. Roberts, R.H. Ryder, and R. Viswanathan: J. Press. Vessel Technol., 1985, vol. 107, p. 247.

K. Laha, K.S. Chandravathi, P. Parameswaran, S. Goyal, and M.D. Mathew: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 1174–86.

J.N. Dupont: Microstructural Characterization and Modeling of Dissimilar Weld Failures Involving Grade 91, vol. 18052, 2016.

D.H. Bechetti, J.N. DuPont, J.J. de Barbadillo, B.A. Baker, and M. Watanabe: Metall. Mater. Trans. A, 2015, vol. 46, pp. 739–55.

J.O. Andersson, T. Helander, L. Höglund, P. Shi, and B. Sundman: Calphad Comput. Coupling Phase Diagrams Thermochem., 2002, vol. 26, pp. 273–312.

H. Larsson: Calphad Comput. Coupling Phase Diagrams Thermochem., 2014, vol. 47, pp. 1–8.

H. Larsson and L. Höglund: Calphad Comput. Coupling Phase Diagrams Thermochem., 2009, vol. 33, pp. 495–501.

Special Metals: 2012, vol. 2012, pp. 1–12.

J.C. Lippold, S.D. Kiser, and J.N. DuPont: Welding Metallurgy and Weldability of Nickel-Base Alloys, Wiley, New York, 2011.

A.A. Gazder, F. Al-Harbi, H.T. Spanke, D.R.G. Mitchell, and E. V. Pereloma: Ultramicroscopy, 2014, vol. 147, pp. 114–32.

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279–88.

J.N. Dupont and C.S. Kusko: Weld. Journal-New York-, 2007, vol. 86, p. 51.

M. Łomozik and A. Zielińska-Lipiec: Arch. Metall. Mater., 2008, vol. 53, pp. 1025–34.

KW Andrews: J. Iron Steel Inst., 1965, vol. 203, pp. 721–7.

Vallourec & Mannesmann Tubes: The T/P91 Book, 1999.

C.G. Panait, W. Bendick, A. Fuchsmann, A.F. Gourgues-Lorenzon, and J. Besson: Int. J. Press. Vessel. Pip., 2010, vol. 87, pp. 326–35.

J. Hald: Materials at High Temperatures, vol. 21, Maney Publishing, London, 2004, pp. 41–46.

A. Di Gianfrancesco, S. TiberiVipraio, and D. Vendit: Procedia Eng., 2013, vol. 55, pp. 27–35.

29 G. Dimmler, P. Weinert, E. Kozeschnik, and H. Cerjak: Mater. Charact., 2003, vol. 51, pp. 341–52.

J.P. Galler, J.N. DuPont, S.S. Babu, and M. Subramanian: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 2765–83.

D.A. Porter, K.E. Easterling, and M.Y. Sherif: Phase Transformations in Metals and Alloys. CRC press, Boca Raton,, 2009.

S. Kou: Welding Metallurgy, 2002.

J.E. and W.G. G. Campbell: Trends Weld. Res. United States, 1981, pp. 443–70.

R. Nicholson.: Met. Technol., 1984, vol. 11, pp. 115–24.

J.P. Galler, J.N. DuPont, S.S. Babu, and M. Subramanian: Metall. Mater. Trans. A, 2019, vol. 50, pp. 2201–17.

Acknowledgments

The authors would like to express their appreciation to the Manufacturing and Materials Joining Innovation Center (Ma2JIC) and the National Science Foundation for providing funding for this study and the Electric Power Research Institute for their mentorship. The authors would also recognize Michelle Kent and Professor Rick Vinci for their assistance with the nanoindentation testing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 23, 2019.

Rights and permissions

About this article

Cite this article

Orzolek, S., DuPont, J. & Siefert, J. Microstructural Evolution of Dissimilar Metal Welds Involving Grade 91. Metall Mater Trans A 51, 2222–2238 (2020). https://doi.org/10.1007/s11661-020-05715-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05715-2