Abstract

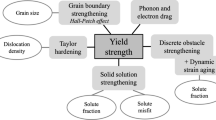

Bridging continuum-scale description of uniaxial tensile plastic stress–strain behavior with adjacent mesoscale deformation models is important and, hence, requires identification of appropriate physical processes and the associated parameters. In this work, a comprehensive phenomenological model (CPM) for true stress–true strain behavior of a polycrystalline material in the plastic regime was developed based on the postulation of physical processes, viz. dislocation nucleation, multiplication, and annihilation, satisfying the statistical perception of dislocation evolution during deformation. Incorporation of these processes through intricate formulations using physical parameters, such as dislocation density, dynamic mean-free-path (MFP), fixed MFP etc. demonstrated a precise fit of a uniform tensile plastic flow curve and of its spin-off work-hardening (WH) behavior, simultaneously. Variation in the calculated parameters for different stress–strain responses of different alloy systems and the sensitivity analyses helped in appreciating the discrete modular nature of the model. Precise fits in both plastic stress–strain and WH responses using the same set of coefficients ensured the CPM to be reliable in simulating realistic uniaxial stress–strain plots from the physical parameters for various alloys. The model advances the understanding of phenomenological modeling especially in terms of incorporation of the dislocation nucleation mechanism in the evolution process, ensuing explicit expression for dislocation evolution with strain and grain size dependence. The present approach is deemed appropriate for linking the length scales in the multiscale description of deformation.

Similar content being viewed by others

Notes

INCONEL is a trade name designating a series of nickel alloys produced by the International Nickel Co.

ZIRLO is a registered trademark of Westinghouse Electric Company LLC, its Affiliates and/or its Subsidiaries in the United States of America.

References

P. Ludwik: Verlag Von Julius. Springer, Leipzig, 1909, p. 32.

J.A. Moriarty, V. Vitek, V.V. Bulatov, and S. Yip: J. Comput. Aided Mater. Des., 2002, vol. 9, pp. 99–132.

V. Bulatov, F.F. Abraham, L. Kubin, B. Devincre, and S. Yip: Nature, 1998, vol. 391, pp. 669–72.

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter: Nat. Mater., 2002, vol. 1, pp. 45–48.

S. Yip: Nat. Mater., 2003, vol. 2, pp. 3–5.

P. Schall, I. Cohen, D.A. Weitz, and F. Spaepen: Science, 2004, vol. 305, pp. 1944–48.

G.I. Taylor: Proc. R. Soc. Lond. Ser. A, 1934, 145, 362–87.

U. Kocks, A. Argon, and M. Ashby: Thermodynamics and Kinetics of Slip, Pergamon Press, 1975.

E. Orowan: Z. Phys., 1934, vol. 89, pp. 634–59.

M. Polanyi: Z. Phys., 1934, vol. 89, pp. 660–64.

Y. Bergström: Mater. Sci. Eng., 1970, vol. 5, pp. 193–200.

G. Malygin: Phys. Status Solidi A, 1990, vol. 119, pp. 423–36.

T.C. Resende, S. Bouvier, F. Abed-Meraim, T. Balan, and S.-S. Sablin: Int. J. Plasticity, 2013, vol. 47, pp. 29–48.

O. Bouaziz, D. Barbier, J. Embury, and G. Badinier: Philos. Mag., 2013, vol. 93, pp. 247–55.

B. Choudhary and J. Christopher: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 2642–55.

I. Beyerlein and C. Tomé: Int. J. Plasticity, 2008, vol. 24, pp. 867–95.

A. Ramazani, K. Mukherjee, U. Prahl, and W. Bleck: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3850–69.

I. Watanabe, D. Setoyama, N. Iwata, and K. Nakanishi: Int. J. Plasticity, 2010, vol. 26, pp. 570–85.

N. Bertin, L. Capolungo, and I. Beyerlein: Int. J. Plasticity, 2013, vol. 49, pp. 119–44.

H. Zhang, X. Dong, D. Du, and Q. Wang: Mater. Sci. Eng. A, 2013, 564, 431–41.

E. Rauch, J. Gracio, F. Barlat, and G. Vincze: Modell. Simul. Mater. Sci. Eng., 2011, vol. 19, p. 035009.

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, and D. Raabe: Acta Mater., 2010, vol. 58, pp. 1152–1211.

A. Ma, F. Roters, and D. Raabe: Acta Mater., 2006, vol. 54, pp. 2169–79.

D. Ludwigson: Metall. Trans., 1971, vol. 2, pp. 2825–28.

E. Voce: J. Inst. Met., 1948, vol. 74, pp. 537–62.

J.H. Hollomon: Trans. AIME, 1945, vol. 12, pp. 1–22.

W. Ramberg and W.R. Osgood: Technical Note No. 902, National Advisory Committee for Aeronautics, Washington, DC.

T. Li, J. Zheng, and Z. Chen: SpringerPlus, 2016, vol. 5, pp. 1316–27.

U. Kocks and H. Mecking: Progr. Mater. Sci., 2003, vol. 48, pp. 171–273.

J. Mittra, J. Dubey, U. Kulkarni, and G. Dey: Mater. Sci. Eng. A, 2009, 512, 87–91.

H.Q. Ang, T.B. Abbott, S. Zhu, and M.A. Easton: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 1–15.

P. Schall, M. Feuerbacher, M. Bartsch, U. Messerschmidt, and K. Urban: Philos. Mag. Lett., 1999, vol. 79, pp. 785–96.

F. Barlat, M. Glazov, J. Brem, and D. Lege: Int. J. Plasticity, 2002, vol. 18, pp. 919–39.

U. Kocks: J. Eng. Mater. Technol., 1976, vol. 98, pp. 76–85.

Y. Estrin: in Unified Constitutive Laws of Plastic Deformation, A.S. Krausz and K. Krausz, eds., Academic Press, San Diego, California, USA, 1996, pp. 69–106.

G.E. Deiter, Mechanical Metallurgy, SI Metric Edition ed., McGraw Hill, London, UK, 1988.

U.F. Kocks and H. Mecking: in Dislocation Modelling of Physical Systems, M.F. Ashby, R. Bullough, C.S. Hartley, and J.P. Hirth, eds., Pergamon, 1981, pp. 173–92.

C. Cáceres and P. Lukáč: Philos. Mag., 2008, vol. 88, pp. 977–89.

P. Partridge: Metall. Rev., 1967, vol. 12, pp. 169–94.

C. Tomé and U. Kocks: Acta Metall., 1985, vol. 33, pp. 603–21.

Acknowledgments

We thank Drs. A. Sarkar and S. Khan, Mechanical Metallurgy Division, BARC, for providing raw tensile data and optical microstructures, respectively, for ZIRLO and Alloy 693 in the present study.

Data availability

The raw and processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 7, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mittra, J., Kumbhar, N.T. Dislocation-Evolution Based Comprehensive Phenomenological Model for Continuum-Scale Description of Stress–Strain and Work-Hardening Behavior. Metall Mater Trans A 51, 1528–1542 (2020). https://doi.org/10.1007/s11661-019-05612-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05612-3