Abstract

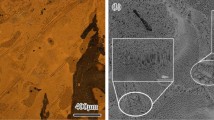

Nowadays, the tolerance of grain boundaries (GBs) is a crucial subject of single crystal (SX) superalloys. Quantitatively deciphering the effect of GBs on the interfacial stability may provide theoretical guidance for the technological design and engineering application of SX superalloys. In this article, [001] tilt artificial GBs with grain boundary angles (GBAs) of 5, 15, 25, 35, and 45 deg, respectively, have been prepared by directional solidification for PAW1484 SX superalloy. The microstructural evolution at GBs under thermal exposure at 1070 °C up to 1000 hours was quantitatively investigated. It has been revealed that low-angle grain boundaries (LAGBs) (< 15 deg) maintained a straight and narrow interface and have no precipitates (mainly carbides) around GBs. For GBAs higher than 25 deg, however, the γ′ layer was widened and coherent MC carbides with orientation relationships [001]MC//[001]matrix and 〈001〉MC//〈001〉matrix, together with blocky and closely spaced M6C carbides, were precipitated. By carefully scaling, the width of the γ′ layer and the ratio of carbides to the γ′ layer were quantitatively determined as a function of GBAs and thermal exposure time. Furthermore, it has been confirmed that the topological-closed-packed (TCP) phase precipitated along the 45 deg GB with the increase of thermal exposure time.

Similar content being viewed by others

References

Le Graverend J-B, Cormier J, and Gallerneau F (2014) Int J Plasticity 59:55–83.

Roger C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, United Kingdom, 2008.

J.D. Nystrom, T.M. Pollock, W.H. Murphy, and A. Garg: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 2443–52.

G. Lvov, V. Levit, and M. Kaufman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1669–79.

Q. Chen, N. Jones, and D. Knowles: Acta Mater., 2002, vol. 50, pp. 1095–1112.

W. Sha: Scripta Mater., 2000, vol. 42, pp. 549–53.

M.D. Sangid, H. Sehitoglu, and T. Niendorf: Mater. Sci. Eng.: A, 2010, vol. 527, pp. 7115–25.

Petr Lukáš, Josef Čadek, and Ludvik Kunz: Kovove Mater., 2005, vol. 43, pp. 5–19.

B. Kear and B. Piearcey: AIME Trans., 1967, vol. 239, pp. 1209–15.

J.C. Stinville, K. Gallup, and T.M. Pollock: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 2516–29.

Q. Chen, C. Jones, and D. Knowles: Mater. Sci. Eng.: A, 2004, vol. 385, pp. 402–18.

Y. Patel, P.F. Browning, and M.D. Fitzpatrick: ASME Turbo Expo, 2000, p. V004T01A005.

J. Li, J. Zhao, S. Liu, and M. Han: Superalloys, 2008, pp. 443–51.

S. Tin, T.M. Pollock, and W. Murphy: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1743–53.

Q. Li, J. Shen, and L. Qin: J. Alloys Compd., 2016, vol. 691, pp. 997–1004.

M.M. Ter Vehn: Superalloys, 1966, p. 471.

X. Yang, H. Dong, and W. Wang: Mater. Sci. Eng. A, 2004, vol. 386, pp. 129–39.

J.W. Aveson, P.A. Tennant, and B.J. Foss: Acta Mater., 2013, vol. 61, pp. 5162–71.

M. Newell, N. D’Souza, and N.R. Green: Mater. Sci. Eng. A, 2005, vol. 413, p. 567.

W. Bogdanowicz, R. Albrecht, and J. Sieniawski: J. Cryst. Growth, 2014, vol. 401, pp. 418–22.

T.M. Pollock and S. Tin: J. Propul. Power, 2006, vol. 22, pp. 361–74.

E.W. Ross and K.S. O’Hara: Superalloys, 1996, pp. 19–25.

K. Harris and J.B. Wahl: Superalloys, 2004, pp. 45–52.

D.M. Shah and A. Cetel: Superalloys, 2000, pp. 295–304.

L. He, Q. Zheng, and A. Tieu: Mater. Sci. Eng.: A, 2005, vol. 397, pp. 297–304.

A. Koul and R. Castillo: Metall. Trans. A, 1988, vol. 19A, pp. 2049–66.

Z. Yu, Y. Zheng, and Q. Feng: Scripta Mater., 2017, vol. 128, pp. 23–26.

M. Huang, L. Zhuo, and J. Li: Mater. Sci. Eng.: A, 2015, vol. 640, pp. 394–401.

W. Sun, X. Qin, and L. Zhou: Mater. Design, 2015, vol. 69, pp. 81–88.

X.Z. Qin, J.T. Guo, and H.Q. Ye: Mater. Sci. Eng.: A, 2008, vol. 485, pp. 74–79.

W. Zhixun, P. Haiqing, and Y. Zhufeng: Rare Met. Mater. Eng., 2015, vol. 44, pp. 1873–78.

S. Gao, Y. Zhou, and T. Jin: J. Alloys Compd., 2014, vol. 610, pp. 589–93.

Dubiel B, Kalemba R, Kąc S (2017) Mater Charact 131:266–76.

B. Dubiel, P. Indyka, and A. Radziszewska: J. Alloys Compd., 2018, vol. 731, pp. 693–703.

I. Manna, S. Pabi, and W. Gust: Int. Mater. Rev., 2001, vol. 46, pp. 53–591.

V.V. Bulatov, B.W. Reed, and M. Kumar: Acta Mater., 2014, vol. 65, pp. 161–75.

D.L. Olmsted, E.A. Holm, and S.M. Foiles: Acta Mater., 2009, vol. 57, pp. 3704–13.

M.D. Sangid, T. Ezaz, and I.M. Robertson: Acta Mater., 2011, vol. 59, pp. 283–96.

R.J. Mitchell, H.Y. Li, and Z.W. Huang: J. Mater. Process. Technol., 2009, vol. 209, pp. 1011–17.

P. Kontis, E. Alabort, and D. Barba: Acta Mater., 2017, vol. 124, pp. 489–500.

H.L. Danflou, M. Macia, and T. Khan: Superalloys, 1996, pp. 119–27.

L. Jiang, R. Hu, and H. Fu: Mater. Sci. Eng.: A, 2012, vol. 536, pp. 37–44.

Kaur I, Gust W (1989) Who is god. In: Kaur J, Gust J (eds) Fundamentals of Grain and Interphase Boundary Diffusion. Ziegler Press, Stuttgart

Y.S. Lim, D.J. Kim, and S.W. Kim: Mater. Charact., 2014, vol. 96, pp. 28–39.

H.U. Hong, H.W. Jeong, and I.S. Kim: Phil. Mag., 2012, vol. 92, pp. 2809–25.

C.T. Sims: Superalloys II, Wiley & Sons, New York, NY, 1987, p. 1.

Y. Jinxia, Z. Qi, and H. Zhuangqi: J. Mater. Sci., 2006, vol. 41, pp. 6476–78.

X. Dong, X. Zhang, and K. Du: J. Mater. Sci. Technol., 2012, vol. 28, pp. 1031–38.

G. Bai, J. Li, and R. Hu: Mater. Sci. Eng.: A, 2011, vol. 528, pp. 2339–44.

Acknowledgments

This work was financially supported by the National Key Research and Development Program of China (Grant No. 2016YFB0701402), Aeronautical Science Foundation of China (Grant No. 2015ZE21006), National Natural Science Foundation of China (Grant No. 51771020) and the Foundation of Science and Technology on Advanced High Temperature Structural Materials Laboratory, AECC Beijing Institute of Aeronautical Materials, China (Grant No. 6142903190101).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 18, 2019.

Rights and permissions

About this article

Cite this article

Wang, Q., Song, J., Wang, D. et al. Quantified Relation between Grain Boundary Angle and Interfacial Stability of PWA1484 Superalloy during Thermal Exposure. Metall Mater Trans A 51, 380–389 (2020). https://doi.org/10.1007/s11661-019-05510-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05510-8