Abstract

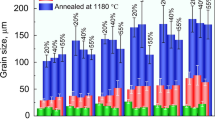

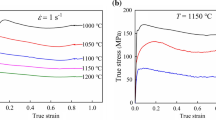

Microstructures, especially grain boundary character distributions (GBCDs), are characterized in specimens of GH4698 alloy submitted to hot compression and subsequent solution annealing. This investigation quantifies and provides a detailed description of the generation and growth of twins during annealing to evaluate the applicability of optimized GBCDs in hot-worked Ni-based superalloys. The grain size and number of twin boundaries depend on the processing parameters. Significant optimization of the GBCD can be achieved by a coupled process of hot compression conducted at small strain (ε = 0.1) and prolonged solution treatment at low temperature (T = 1070 °C, t = 60 min), as shown by the high values of NAve (the average number of Σ3 grain boundaries in a single grain) and R (the ratio of the area-weighted average grain size without considering twins as the boundary with respect to the grain size with twins). The key to optimizing the GBCD is to activate strain-induced boundary migration (SIBM) while inhibiting dynamic recrystallization and recrystallization, thus resulting in the formation of microstructures with a high proportion (74%) of Σ3n (n = 1, 2, 3) boundaries. The SIBM process includes the formation of new Σ3 boundaries through accidental growth mechanisms behind the migrated grain boundaries and interfacial reactions between Σ3n boundaries to interrupt the connectivity of random high-angle grain boundary networks.

Graphical Abstract

Similar content being viewed by others

References

Watanabe T (2011) Grain boundary engineering: Historical perspective and future prospects. J Mater Sci 46:4095–4115

Xia S, Li H, Liu TG, Zhou BX (2011) Appling grain boundary engineering to alloy 690 tube for enhancing intergranular corrosion resistance. J Nucl Mater 416:303–310

Zhang JY, Xu LY, Han YD, Zhao L, Xiao B (2020) New perspectives on the grain boundary misorientation angle dependent intergranular corrosion of polycrystalline nickel-based 625 alloy. Corros Sci 172:108718

Kobayashi S, Kobayashi R, Watanabe T (2016) Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater 102:397–405

Tokita S, Kokawa H, Sato YS, Fujii HT (2017) In situ EBSD observation of grain boundary character distribution evolution during thermomechanical process used for grain boundary engineering of 304 austenitic stainless steel. Mater Charact 131:31–38

Randle V, Coleman M (2009) A study of low-strain and medium-strain grain boundary engineering. Acta Mater 57:3410–3421

Huang WJ, Chai LJ, Li ZJ, Yang XS, Guo N, Song B (2016) Evolution of microstructure and grain boundary character distribution of a tin bronze annealed at different temperatures. Mater Charact 114:204–210

Zhang P, Hu C, Zhu Q, Ding CG, Qin HY (2015) Hot compression deformation and constitutive modeling of GH4698 alloy. Mater Des 65:1153–1160

Tan CL, Weng F, Sui S, Chew YX, Bi GJ (2021) Progress and perspectives in laser additive manufacturing of key aeroengine materials. Int J Mach Tool Manu 170:103804

Liu TG, Xia S, Li H, Zhou BX, Bai Q, Su C, Cai ZG (2013) Effect of initial grain sizes on the grain boundary network during grain boundary engineering in alloy 690. J Mater Res 28:1165–1176

Athreya CN, Deepak K, Dl K, de Boer B, Mandal S, Subramanya SV (2019) Role of grain boundary engineered microstructure on high temperature steam oxidation behaviour of Ni based superalloy alloy 617. J Alloy Comp 778:224–233

Guan XJ, Shi F, Jia ZP, Li XW (2020) Grain boundary engineering of AL6XN super-austenitic stainless steel: distinctive effects of planar-slip dislocations and deformation twins. Mater Charact 170:110689

Hu HL, Zhao MJ, Chen SH, Rong L (2020) Effect of grain boundary character distribution on hydrogen embrittlement in Fe-Ni based alloy. Mater Sci Eng A 780:139201

Xia S, Zhou BX, Chen WJ (2009) Grain cluster microstructure and grain boundary character distribution in alloy 690. Metall Mater Trans A 40:3016–3030

Prithiv TS, Bhuyan P, Pradhan SK, Subramanya SV, Mandal S (2018) A critical evaluation on efficacy of recrystallization vs strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy. Acta Mater 146:187–201

Detrois M, Rotella J, Goetz RL, Helmink RC, Tin S (2015) Grain boundary engineering of powder processed Ni-base superalloy RR1000: Influence of the deformation parameters. Mater Sci Eng A 627:95–105

Li B, Tin S (2014) The role of deformation temperature and strain on grain boundary engineering of Inconel 600. Mater Sci Eng A 603:104–113

Bai Q, Zhao Q, Xia S, Wang BS, Zhou BX, Su C (2017) Evolution of grain boundary character distributions in alloy 825 tubes during high temperature annealing: Is grain boundary engineering achieved through recrystallization or grain growth? Mater Charact 123:178–188

Barr CM, Leff AC, Demott RW, Doherty RD, Taheri ML (2018) Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater 144:281–291

Bober DB, Lind J, Mulay RP, Rupert TJ, Kumar M (2017) The formation and characterization of large twin related domains. Acta Mater 129:500–509

Yang XY, Wang P, Huang M (2022) Grain boundary evolution during low-strain grain boundary engineering achieved by strain-induced boundary migration in pure copper. Mater Sci Eng A 833:142532

Kumar M, Schwartz AJ, King WE (2002) Microstructural evolution during grain boundary engineering of low to medium stacking fault energy fcc materials. Acta Mater 50:2599–2612

Shimada M, Kokawa H, Wang ZJ, Sato YS, Karibe I (2002) Optimization of grain boundary character distribution for intergranular corrosion resistant 304 stainless steel by twin-induced grain boundary engineering. Acta Mater 50:2331–2341

Mandal S, Sivaprasad PV, Raj B, Subramanya SV (2008) Grain boundary microstructural control through thermomechanical processing in a titanium-modified austenitic stainless steel. Metall Mater Trans A 39:3298–3307

Kaithwas CK, Bhuyan P, Pradhan SK, Mandal S (2018) Microstructure evolution during low-strain thermo-mechanical processing and its repercussion on intergranular corrosion in alloy 600H. Mater Charact 145:582–593

Nye A, Leff AC, Barr CM, Taheri ML (2018) Direct observation of recrystallization mechanisms during annealing of Cu in low and high strain conditions. Scripta Mater 146:308–311

Kaithwas CK, Bhuyan P, Mandal S (2020) Assessing the potential of sparsely nucleated recrystallized grains to lead grain boundary engineering during extending annealing in alloy 600H. Mater Charact 168:110538

Liu TG, Xia S, Li H, Zhou BX, Bai Q (2014) The highly twinned grain boundary network formation during grain boundary engineering. Mater Lett 133:97–100

Brandon DG (1966) The structure of high-angle grain boundaries. Acta Metall 14:1479–1484

Takayama Y, Szpunar JA (2004) Stored energy and Taylor factor relation in an Al-Mg-Mn alloy sheet worked by continuous cyclic bending. Mater Trans 45:2316–2325

Mahajan S, Pande CS, Imam MA, Rath BB (1997) Formation of annealing twins in fcc crystals. Acta Mater 45:2633–2638

Randle V (1999) Mechanism of twinning-induce grain boundary engineering in low stacking-fault energy materials. Acta Mater 47:4187–4196

Meyers MA, Murr LE (1978) A model for the formation of annealing twins in fcc metals and alloys. Acta Metall 26:951–962

Lopez-Sanchez MA, Tommasi A, Barou F, Quey R (2020) Dislocation-driven recrystallization in AZ31B magnesium alloy imaged by quasi-in situ EBSD in annealing experiments. Mater Charact 165:110382

Baik SL, Gupta RK, Kumar KS, Seidman DN (2021) Temperature increases and thermoplastic microstructural evolution in adiabatic shear bands in a high-strength and high-toughness 10 wt.% Ni steel. Acta Mater 205:116568

Dhal A, Panigrahi SK, Shunmugam MS (2017) Insight into the microstructural evolution during cryo-severe plastic deformation and post-deformation annealing of aluminum and its alloys. J Alloy Comp 726:1205–1219

He GA, Tan LM, Liu F, Huang L, Huang ZW, Jiang L (2017) Unraveling the formation mechanism of abnormally large grains in an advanced polycrystalline nickel base superalloy. J Alloy Comp 718:405–413

Wang X, Huang ZW, Cai B, Zhou N, Magdysyuk O, Gao YF, Srivatsa S, Tan LM, Jiang L (2019) Formation mechanism of abnormally large grains in a polycrystalline nickel-based superalloy during heat treatment processing. Acta Mater 168:287–298

Charpagne MA, Franchet JM, Bozzolo N (2018) Overgrown grains appearing during sub-solvus heat treatment in a polycrystalline γ-γ´ nickel-based superalloy. Mater Des 144:353–360

Bozzolo N, Agnoli A, Souai N, Bernacki M, Loge RE (2013) Strain induced abnormal grain growth in nickel base superalloys. Mater Sci Forum 753:321–324

Hibbard GD, Radmilovic V, Aust KT, Erb U (2008) Grain boundary migration during abnormal grain growth in nanocrystalline Ni. Mater Sci Eng A 494:232–238

Miller VM, Johnson AE, Torbet CJ, Pollock TM (2016) Recrystallization and the development of abnormally large grains after small strain deformation in a polycrystalline nickel-based superalloy. Metall Mater Trans A 47:1566–1574

Gleiter H (1969) The mechanism of grain boundary migration. Acta Metall 17:565–573

Li HZ, Liu XG, Zhang WW, Liu PW, Guo SL, Qin HY, Tian Q (2022) Microstructure evolution and dynamic recrystallization mechanism during thermal deformation of GH4698 superalloy. J Mater Sci 57:2969–2987

Jiang H, Dong JX, Zhang MC, Yao ZH (2016) Evolution of twins and substructures during low strain rate hot deformation and contribution to dynamic recrystallization in alloy 617B. Mater Sci Eng A 649:369–381

Pradhan SK, Mandal S, Athreya CN, Babu KA, de Boer B, Subramanya SV (2017) Influence of processing parameters on dynamic recrystallization and the associated annealing twin boundary evolution in a nickel base superalloy. Mater Sci Eng A 700:49–58

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face centered cubic metals: I. Grain Bound Energy Acta Mater 57:3694–3703

Bozzolo N, Bernacki M (2020) Viewpoint on the formation and evolution of annealing twins during thermomechanical processing of fcc metals and alloys. Metall Mater Trans A 51:2665–2684

Jin Y, Lin B, Rollett AD, Rohrer GS, Bernacki M, Bozzolo N (2015) Thermo-mechanical factors influencing annealing twin development in nickel during recrystallization. J Mater Sci 50:5191–5203

Cahoon JR, Li QY, Richards NL (2009) Microstructural and processing factors influencing the formation of annealing twins. Mater Sci Eng A 526:56–61

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: N. Ravishankar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Liu, X., Wang, S. et al. An evaluation of optimized grain boundary character distribution in hot-worked GH4698 superalloy. J Mater Sci 58, 1382–1402 (2023). https://doi.org/10.1007/s10853-022-08077-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08077-9