Abstract

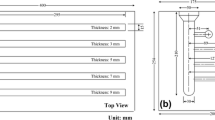

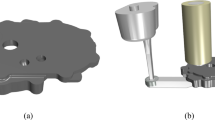

Fluidity is an important factor defining the castability of aluminum casting alloys. In this study, the influence of Ce addition on the fluidity of A356 alloy was investigated using a multichannel fluidity test mold. There is a non-monotonic relationship between fluidity length and Ce content. Addition of Ce below 0.3 wt pct was shown to increase the fluidity of A356 alloy. The fluidity length of the alloy with 0.3 wt pct Ce improved from 93.2 to 130.2 mm compared with that of A356 alloy due to the refinement of α-Al and the modification of eutectic Si. The addition of Ce could provide nucleation particles and cause constitutional undercooling in A356 alloy. Furthermore, the addition of Ce decreased the eutectic temperature and induced twinning of Si. However, with a higher Ce content, the fluidity length dramatically decreased because of the formation of intermetallic compounds. When the content of Ce is 0.5 wt pct, a mass of reticular Al-20Si-10Mg-3Fe-Ce intermetallic compounds was found in the melt. When the Ce content further increased to 0.7 wt pct, the fluidity worsened (73.3 mm). Excess Ce element reacts with Ti in the alloy to form the Al-17Ce-12Ti-2Si phase, resulting in the formation of coarse primary dendrites of α-Al, which would damage the fluidity of A356 alloy.

Similar content being viewed by others

References

A.M. Cardinale, D. Macciò, G. Luciano, E. Canepa,and P. Traverso: J. Alloys Compd.,2017, vol. 695, pp. 2180-2189.

Z. Chen, C. Ma,and P. Chen: Int. J. Miner., Metall. Mater.,2012, vol. 19, pp. 131-135.

Feng J, Ye B, Zuo LJ, Wang QD, Wang Q, Jiang H, Ding W (2017) Metall. Mater. Trans. A 48:4632–4644

M. Zhu, Z. Jian, G. Yang,and Y. Zhou: Mater. Des.,2012, vol. 36, pp. 243-249.

B.K. Kang,and I. Sohn: Metall. Mater. Trans. A,2018, vol. 49, pp. 5137-5145.

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai,and M. Chakraborty: J. Alloys Compd.,2008, vol. 456, pp. 201-210.

G. Yang. H.R. Qi, and Q Shi: Light alloy. Fabr. Technol.,2007, vol. 35, pp. 19-22+53

A.K. Dahle, P.A. Tondel, C.J. Paradies,and L. Arnberg: Metall. Mater. Trans. A,1996, vol. 27, pp. 2305-2313.

Q. Han,and H. Xu: Scr. Mater.,2005, vol. 53, pp. 7-10.

Heidarzadeh A, Emamy M, Rahimzadeh A, Soufi R, Heidary SB, Nasibi S (2013) J. Mater. Eng. Perform. 23:469–476.

M. Di Sabatino, L. Arnberg,and D. Apelian: Int. J. Metalcast.,2008, vol. 2, pp. 17-27.

K. Puparattanapong, P. Pandee, S. Boontein,and C. Limmaneevichitr: Trans. Indian Inst. Met.,2018, vol. 71, pp. 1583-1593.

X. Song, H. Yan, Q. Wu, and Z. Hu: Int. J. Cast Met. Res., 2018, pp. 1-8.

W. Prukkanon, N. Srisukhumbowornchai,and C. Limmaneevichitr: J. Alloys Compd.,2009, vol. 477, pp. 454-460.

B. Li, H. Wang, J. Jie,and Z. Wei: J. Alloys Compd.,2011, vol. 509, pp. 3387-3392.

G. Wang, X. Bian, W. Wang,and J. Zhang: Mater. Lett.,2003, vol. 57, pp. 4083-4087.

Y. Dong, R. Zheng, X. Lin, J. Ye,and L. Sun: J. Rare Earths,2013, vol. 31, pp. 204-208.

C. Morando, O. Fornaro, O. Garbellini,and H. Palacio: Procedia Mater. Sci.,2015, vol. 8, pp. 959-967.

A. Knuutinen, K. Nogita, S.D. McDonald,and A.K. Dahle: J. Light Met.,2001, vol. 1, pp. 229-240.

U. Patakham, J. Kajornchaiyakul,and C. Limmaneevichitr: J. Alloys Compd.,2013, vol. 575, pp. 273-284.

Z. Chen, C. Ma,and P. Chen: Trans. Nonferrous Met. Soc. China,2012, vol. 22, pp. 42-46.

Z. Chen, X. Hao, J. Zhao,and C. Ma: Trans. Nonferrous Met. Soc. China,2013, vol. 23, pp. 3561-3567.

S. Zhang, Y. Zhao, X. Cheng, G. Chen,and Q. Dai: J. Alloys Compd.,2009, vol. 470, pp. 168-172.

Y. Han, K. Li, J. Wang, D. Shu,and B. Sun: Mater. Sci. Eng. A,2005, vol. 405, pp. 306-312.

W. Jiang, Z. Fan, D. Liu, D. Liao, X. Dong,and X. Zong: Mater. Sci. Eng. A,2013, vol. 560, pp. 396-403.

C. Xu, W. Xiao, S. Hanada, H. Yamagata,and C. Ma: Mater. Charact.,2015, vol. 110, pp. 160-169.

L. Zheng, L.H. Lin,and C.Q. Chun: Solid State Phenom.,2015, vol. 217-218, pp. 340-346.

L. Jin, Y. B. Kang, P. Chartrand,and C.D. Fuerst: Calphad,2011, vol. 35, pp. 30-41.

Y. C. Tsai, S. L. Lee,and C. K. Lin: J. Chin. Inst. Eng.,2011, vol. 34, pp. 609-616.

E.M. Elgallad, H.W. Doty, S.A. Alkahtani,and F.H. Samuel: Adv. Mater. Sci. Eng., 2016. https://doi.org/10.1155/2016/5027243

B. Zhao, Q. Cai, X. Li, B. Li,and J. Cheng: Met. Mater. Int.,2018, vol. 24, pp. 945-954.

S. Z. Lu,and A. Hellawell: Metall. Trans. A,1987, vol. 18, pp. 1721-1733.

Acknowledgment

This work was supported by the Sichuan Science and Technology Program (No. 2018GZ0011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 9, 2019.

Rights and permissions

About this article

Cite this article

Niu, G., Mao, J. & Wang, J. Effect of Ce Addition on Fluidity of Casting Aluminum Alloy A356. Metall Mater Trans A 50, 5935–5944 (2019). https://doi.org/10.1007/s11661-019-05458-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05458-9