Abstract

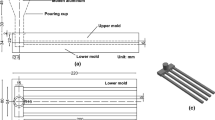

A356 with scandium (Sc) addition provides interesting results beyond costs. For the practical use of Sc, the effects of Sc on castability must be considered. Fluidity and hot cracking are important factors defining the castability of aluminum casting alloys. In the present work, the influence of Sc addition on the castability of A356 hypoeutectic Al–Si alloy was investigated, which was evaluated through fluidity and hot cracking susceptibility. The fluidity of the alloys was studied by measuring the total volume of solidified aluminum in a multi-channel mold. The hot cracking susceptibility of the alloys was evaluated by using a constrained-rod casting mold test. The results of the fluidity and hot cracking susceptibility test were supported by microstructural analysis. The results indicate that 0.2 wt% Sc addition significantly increases the fluidity of A356 alloy, due to the grain refinement and eutectic Si modification by changing the solidification mode. However, the fluidity slightly decreases when the Sc content increases to 0.4 wt% due to the formation of primary Al2Si2Sc intermetallic phase. The hot cracking of A356 alloy was completely diminished when Sc was added to the alloy.

Reproduced with permission from Pandee et al. [40]

Similar content being viewed by others

References

Arnberg L, and Mo A, Castability-Fluidity and Hot Tearing, Metals Handbook, ASM (2008), p 375.

Flemings M C, Solidification Processing, Wiley Online Library (1974).

Davidson C, Viano D, Lu L, and StJohn D, Int J Cast Met Res 19 (2006) 59.

Eskin D, and Katgerman L, Metall Mater Trans A 38 (2007) 1511.

Ravi K R, Pillai R M, Amaranathan K R, Pai B C, and Chakraborty M, J Alloys Compd 456 (2008) 201.

Kwon Y-D, and Lee Z-H, Mater Sci Eng A 360 (2003) 372.

Dahle A K, Tøndel P A, Paradies C J, and Arnberg L, Metall Mater Trans A 27 (1996) 2305.

Loper C Jr, AFS Trans 47 (1992) 533.

Mollard F, Flemings M, and Niyama E, AFS Trans 95 (1987) 647.

Kotte B, Modern Cast. 75 (1985) 33.

Pan E, and Hu J, Trans Am Foundrym Soc 105 (1997) 413.

Argo D, and Gruzleski J, Int J Cast Met Res 2 (1989) 109.

Easton M, Wang H, Grandfield J, St John D, and E. Sweet, Mater Forum 28 (2004) 224.

Rosenberg R, Flemings M, and Taylor H, Trans Am Foundrym Soc 68 (1960) 518.

Warrington D, and McCartney D, Int J Cast Met Res 3 (1990) 202.

Gruzleski J, and Closset B, The Treatment of Liquid Aluminum-Silicon Alloy, American Foundrymen’s Society, Inc. (1990).

Robles-Hernandez F C, Ramírez J M H, and Mackay R, Al–Si Alloys: Automotive, Aeronautical, and Aerospace Applications, Springer (2017).

Patakham U, Kajornchaiyakul J, and Limmaneevichitr C, J Alloys Compd 542 (2012) 177.

Xu C, Xiao W, Hanada S, Yamagata H, and Ma C, Mater Charact 110 (2015) 160.

Muhammad A, Xu C, Xuejiao W, Hanada S, Yamagata H, Hao L, and M. Chaoli, Mater Sci Eng A 604 (2014) 122.

Pandee P, Gourlay C M, Belyakov S A, Patakham U, Zeng G, and Limmaneevichitr C, J. Alloys Compd 731 (2018) 1159.

Patakham U, Kajornchaiyakul J, and Limmaneevichitr C, J Alloys Compd 575 (2013) 273.

Prukkanon W, Srisukhumbowornchai N, and Limmaneevichitr C, J Alloys Compd 477 (2009) 454.

Patakham U, and Limmaneevichitr C, J Alloys Compd 616 (2014) 198.

Puparattanapong K, and Limmaneevichitr C, Trans Indian Inst Met 69 (2016) 1587.

Prukkanon W, Srisukhumbowornchai N, and Limmaneevichitr C, J Alloys Compd 487 (2009) 453.

Di Sabatino M, Shankar S, Apelian D, and Arnberg L, Influence of Temperature and Alloying Elements on Fluidity of Al–Si Alloys, in TMS Shape Casting - The John Campbell Symposium (2005), p 193.

Çolak M, Kayikci R, and Dispinar D, Trans Indian Inst Met 68 (2015) 275.

Pekguleryuz M, Labelle P, Argo D, and Baril E, Magnesium Diecasting Alloy AJ 62 X with Superior Creep Resistance, Ductility and Diecastability, in Magnesium Technology 2003 as held at the 2003 TMS Annual Meeting (2003), p 201.

Cao G, and Kou S, Mater Sci Eng A 417 (2006) 230.

Toropova L S, Eskin D G, Kharakterova M L, and Dobatkina T V, Advance Aluminum Alloys containing Scandium: Structure and Properties, Gordon and Breach Science, Amsterdam (1998).

Rokhlin L L, Bochvar N R, Rybal’chenko O V, Tarytina I E, and Sukhanov A V, Russ Metall 2012 (2012) 606.

Tyvanchuk A T, Yanson T I, and Kotur B, Russ Metall 20 (1988) 190.

Backerud L, Chai G, and Tamminen J, Solidification Characteristics of Aluminum Alloys. Vol. 2., Foundry alloys, American Foundrymen’s Society, Inc. (1990) p 266.

Malekan M, and Shabestari S, Metall Mater Trans A 40 (2009) 3196.

Schumacher P, Greer A L, Worth J, Evans P V, Kearns M A, Fisher P, and Green A H, Mater Sci Technol 14 (1998) 394.

Greer A L, Bunn A M, Tronche A, Evans P V, and Bristow D J, Acta Mater 48 (2000) 2823.

Dahle A, Arnberg L, and Apelian D, Trans Am Foundrym Soc 105 (1997) 963.

Venkateswaran S, Mallya R, and Seshadri M, Trans Am Foundrym Soc 94 (1986) 701.

Pandee P, Gourlay C M, Belyakov S A, Ozaki R, Yasuda H, and Limmaneevichitr C, Metall Mater Trans A 45 (2014) 4549.

Di Sabatino M, and Arnberg L, Trans Indian Inst Met 62 (2009) 321.

Ram G J, Mitra T, Shankar V, and Sundaresan S, J Mater Process Technol 142 (2003) 174.

Nabawy A M, Samuel A M, Samuel F H, and Doty H W, J Mater Sci 47 (2012) 4146.

Knuutinen A, Nogita K, McDonald S D, and Dahle A K, J Light Met 1 (2001) 241.

Nogita K, Knuutinen A, McDonald S D, and Dahle A K, J. Light Met 1 (2001) 219.

Li S, Sadayappan K, and Apelian D, Metall Mater Trans B 47 (2016) 2979.

Huang H, Fu P-h, Wang Y-x, Peng L-m, and Jiang H-y, Trans Nonferrous Met Soc China 24 (2014) 922.

Acknowledgements

Financial support by the National Research University Project of Thailand’s Office of the Higher Education Commission, the King Mongkut’s University of Technology Thonburi through the “KMUTT 55th Anniversary Commemorative Fund,” and the Royal Thai Government Scholarship (Ministry of Science and Technology) for Mr. Kongkiat Puparattanapong for his Ph.D. study is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puparattanapong, K., Pandee, P., Boontein, S. et al. Fluidity and Hot Cracking Susceptibility of A356 Alloys with Sc Additions. Trans Indian Inst Met 71, 1583–1593 (2018). https://doi.org/10.1007/s12666-018-1293-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1293-0