Abstract

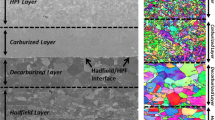

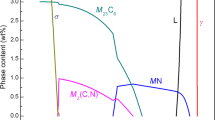

An austenitic Hadfield steel shows highly sustained strain hardening as well as excellent tensile strength and ductility, but its yield strength is relatively low (400 to 500 MPa). In order to overcome this shortcoming, two multi-layer steel (MLS) sheets were fabricated by the hot-roll-bonding of the Hadfield steel with two kinds of martensitic hot-press-forming (HPF) steels. Carburized and decarburized layers were formed near Hadfield/HPF interfaces by the C diffusion from the high-C Hadfield (1.2 pct) to low-C HPF (0.23 and 0.35 pct) layers. The tensile test results indicated that the two MLS sheets were fractured right after the yielding with almost no plastic deformation because the intergranular fracture appeared in the carburized and HPF layers. This intergranular fracture was caused by Cr7C3 carbide precipitation and C segregation at prior austenite grain boundaries as well as considerably high residual stresses generated in both Hadfield and HPF layers. The tempering at 473 K (200 °C) was adopted for relieving residual stresses, while most of grain-boundary carbides remained. The 473 K (200 °C)-tempered MLS sheets showed improved tensile properties over the non-tempered MLS sheets, and well satisfied a rule of mixtures.

Similar content being viewed by others

References

J.G. Kim, S.M. Baek, H.H. Lee, K.-G. Chin, S. Lee, and H.S. Kim: Acta Mater., 2018, vol. 147, pp. 304-12.

Y. Wei, Y. Li, L. Zhu, Y. Liu, X. Lei, G. Wang, Y. Wu, Z. Mi, J. Liu, H. Wang, and H. Gao: Nat. Commun., 2014, vol. 5, pp. 3580-87.

M. Kang, J. Park, S.S. Sohn, D.-H. Ahn, H.S. Kim, W.T. Cho, K.-G. Chin, and S. Lee: Mater. Sci. Eng. A, 2017, vol. 700, pp. 387-96.

J. Park, M. Kang, S.S. Sohn, J.-S. Kim, H.S. Kim, W.T. Cho, and S. Lee: Mater. Sci. Eng. A, 2017, vol. 686, pp. 160-67.

M. Ojima, J. Inoue, S. Nambu, P. Xu, K. Akita, H. Suzuki, and T. Koseki: Scr. Mater., 2012, vol. 66, pp. 139-42.

P. Lhuissier, J. Inoue, and T. Koseki: Scr. Mater., 2011, vol. 64, pp. 970-73.

R.I. Barabash, O.M. Barabash, M. Ojima, Z. Yu, J. Inoue, S. Nambu, T. Koseki, R. Xu, and Z. Feng: Metall. Mater. Trans. A, 2013, vol. 45, pp. 98-108.

J. Inoue, S. Nambu, Y. Ishimoto, and T. Koseki: Scr. Mater., 2008, vol. 59, pp. 1055-58.

R. Cao, X. Yu, Z. Feng, M. Ojima, J. Inoue, and T. Koseki: Metall. Mater. Trans. A, 2016, vol. 47, pp. 6042-55.

J.J. Du, X. Zhang, B.X. Liu, Y.C. Dong, J.H. Feng, C.X. Chen, and F.X. Yin: Mater. Chem. Phys., 2019, vol. 223, pp. 114-21.

O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: Int. J. Plasticity, 2000, vol. 16, pp. 1391-409.

G. Frommeyer, U. Brüx, and P. Neumann: ISIJ Int., 2003, vol. 43, pp. 438-46.

K.H. So, J.S. Kim, Y.S. Chun, K.-T. Park, Y.-K. Lee, and C.S. Lee: ISIJ Int., 2009, vol. 49, pp. 1952-59.

C. Beal, X. Kleber, D. Fabregue, and M. Bouzekri: Mater. Sci. Eng. A, 2012, vol. 543, pp. 76-83.

G. Jung, I.S. Woo, D.W. Suh, and S.-J. Kim: Met. Mater. Int., 2016, vol. 22, pp. 187-95.

C.J. Rüsing, T. Niendorf, J. Lackmann, A. Frehn, and H.J. Maier: Int. J. Mater. Res., 2012, vol. 103, pp. 12-16.

K.-G. Chin, C.-Y. Kang, J. Park, and S. Lee: Met. Mater. Int. 2018, vol. 24, pp. 489-95.

O. Bouaziz, J.P. Masse, G. Petitgand, and M.X. Huang: Adv. Eng. Mater., 2016, vol. 18, pp. 56-59.

W.X. Yu, B.X. Liu, X.P. Cui, Y.C. Dong, X. Zhang, J.N. He, C.X. Chen, and F.X. Yin: Mater. Sci. Eng. A, 2018, vol. 727, pp. 70-77.

S. Nambu, M. Michiuchi, J. Inoue, and T. Koseki: Compos. Sci. Technol., 2009, vol. 69, pp. 1936-41.

B.X. Liu, F.X. Yin, X.L. Dai, J.N. He, W. Fang, C.X. Chen, and Y.C. Dong: Mater. Sci. Eng. A, 2017, vol. 679, pp. 172-82.

D.H. Lee, J.-S. Kim, H. Song, and S. Lee: Met. Mater. Int., 2017, vol. 23, pp. 805-12.

R.M. Horn and R.O. Ritchie: Metall. Trans. A, 1978, vol. 9, pp. 1039-53.

C.L. Briant and S.K. Banerji: Int. Metals Rev., 1978, vol. 23, pp. 164-99.

F. Qin, Y. Li, W. He, X. Zhao, and H. Chen: Met. Mater. Int., 2017, vol. 23, pp. 1087-96.

I.-C. Yi, Y. Ha, H. Lee, A. Zargaran, and N.J. Kim: Met. Mater. Int., 2017, vol. 23, pp. 283-89.

H. Karbasian, A.E. Tekkaya: J. Mater. Process Tech., 2010, vol. 210, pp. 2103-18.

L. Cho, D.H. Sulistiyo, E.J. Seo, K.R. Jo, S.W. Kim, J.K. Oh, Y.R. Cho, and B.C. De Cooman: Mater. Sci. Eng. A, 2018, vol. 734, pp. 416-26.

P.J. Withers and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2001, vol. 17, pp. 355-65.

C. Efstathiou and H. Sehitoglu: Mater. Sci. Eng. A, 2009, vol. 506, pp. 174-79.

M.M. Atabaki, S. Jafari, and H. Abdollah-pour: J. Iron Steel Res. Int., 2012, vol. 19, pp. 43-50.

Y. Matsuoka, T. Iwasaki, N. Nakada, T. Tsuchiyama, and S. Takaki: ISIJ Int., 2013, vol. 53, pp. 1224-30.

D.A. Porter and K.E. Easterling: Phase Transformations in Metals and Alloys, CRC Press, Boca Raton, 2004.

J. Vivas, C. Capdevila, E. Altstadt, M. Houska, I. Sabirov, and D. San-Martin: Met. Mater. Int., 2019, vol. 25, pp. 343-52.

J.C. Ritter and R. McPherson: Metals Technol., 1974, vol. 1, pp. 506-11.

G.M. Xie, Z.G. Luo, G.L. Wang, L. Li, and G.D. Wang: Mater. Trans., 2011, vol. 52, pp. 1709-12.

KiSTi ICSD, ICSD ID: 54159, Coll. Code: 87129.

S.S. Sohn, B.-J. Lee, J.-H. Kwak, and S. Lee: Metall. Mater. Trans. A, 2014, vol. 45A, 3844-56.

W. Woo, V. Em, C.R. Hubbard, H.-J. Lee, and K.S. Park: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8021-27.

Acknowledgments

This work was supported by Brain Korea 21 PLUS Project for Center for Creative Industrial Materials. H. S. Kim acknowledges the support by the National Research Foundation of Korea (NRF) Grant funded by the Korea Government (MSIP) (No. 2014R1A2A1A10051322).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 02, 2018.

Rights and permissions

About this article

Cite this article

Jo, M.C., Park, J., Park, G. et al. Understanding and Avoiding Intergranular Fracture Characteristics of Hadfield/Hot-Press-Forming Multi-Layer Steel Sheets. Metall Mater Trans A 50, 4085–4097 (2019). https://doi.org/10.1007/s11661-019-05346-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05346-2