Abstract

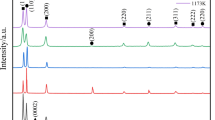

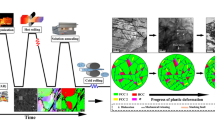

An ultrafine-structured FeCoCrNiMn high-entropy alloy (HEA) was produced by severe cold rolling (SCR) with a 95 pct reduction, and the effect of annealing temperature over a wide range from 573 K to 1373 K (300 °C to 1100 °C) on the microstructure and mechanical properties of this SCRed HEA was systematically investigated. The results show that the microstructure of the single-phase FCC HEA after SCR is greatly refined and mainly comprises ultrafine crystalline, high-density dislocation cell and networks, which substantially improve the hardness and strength. The SCRed HEA starts to recrystallize at an annealing temperature of 773 K (500 °C) and is fully recrystallized at 973 K (700 °C) after 1 hours. The σ phases with a tetragonal structure form upon annealing at 773 K (500 °C), leading to a further enhancement in hardness and strength for the annealed HEA compared to the SCRed HEA. The average grain size remains below 500 nm when the SCRed HEA is annealed at 923 K (650 °C) for 1 hours, indicating that the ultrafine-structured HEA after SCR and subsequent annealing treatment possesses excellent microstructural thermal stability. The SCRed HEAs annealed at 923 K and 973 K (650 °C and 700 °C) exhibit excellent high strength–ductility combinations due to the formation of the fully recrystallized ultrafine-grained microstructure. The strain-rate sensitivity parameter (m value) with different grain sizes, from ultrafine to coarse, was evaluated by strain-rate jump tests. The m value of the HEA increases monotonically with increasing grain size and annealing temperature. Moreover, high-temperature tensile tests demonstrated that the annealed HEAs exhibit superplastic deformation behavior at 973 K and 1073 K (700 °C and 800 °C), and the formation of a Cr-rich phase is found during high-temperature deformation. It is believed that the plastic deformation facilitates the phase decomposition of fine-grained HEAs and grain boundary sliding is the key mechanism of high-temperature deformation.

Similar content being viewed by others

References

B. Cantor, I. T. H. Chang, P. Knight and A. J. B. Vincent: Mater. Sci. Eng. A, 2004, vol. 375-377, pp. 213-218.

J. W. Yeh, S. K. Chen, S. J. Lin, J. Y. Gan, T. S. Chin, T. T. Shun, C. H. Tsau and S. Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299-303.

Z. P. Lu, H. Wang, M. W. Chen, I. Baker, J. W. Yeh, C. T. Liu and T. G. Nieh: Intermetallics, 2015, vol. 66, pp. 67-76.

J.W.Yeh: Ann. Chim. Sci. Mat., 2006, vol. 31, pp. 633-648.

S. Maiti and W.Steurer: Acta Mater., 2016, vol. 106, pp. 87-97.

A. Gali and E. P. George: Intermetallics, 2013, vol. 39, pp. 74-78.

D.Y. Li and Y. Zhang: Intermetallics, 2016, vol. 70, pp. 24-28.

C.-Y. Hsu, J.-W. Yeh, S.-K. Chen, and T.-T. Shun: Metall. Trans. A, 2004, vol. 35A, pp. 1465-69.

Y. Liu, S. Ma, M. C. Gao, C. Zhang, T. Zhang, H.Yang, Z. Wang, and J. Qiao: Metall. Trans. A, 2016, vol. 47, pp. 3312-3321.

Y. Shi, B. Yang, X. Xie, J. Brechtl, K. A. Dahmen, and P. K. Liaw: Corros. Sci., 2017, vol. 119, pp. 33-45.

V. Soare, D. Mitrica, I. Constantin, G. Popescu, I. Csaki, M. Tarcolea, and I. Carcea: Metall. Trans. A, 2014, vol. 46, pp. 1468- 1473.

W. Zhang, P. K. Liaw and Y. Zhang: Sci. China Mater., 2018, vol. 61, pp. 2-22.

D. B. Miracle and O. N. Senkov: Acta Mater., 2017, vol. 122, pp. 448-511.

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E. P. George: Acta Mater., 2013, vol. 61, pp. 5743-5755.

B. Gludovatz, A. Hohenwarter, D. Catoor, E. H. Chang, E. P. George, and R. O. Ritchie: Science, 2014, vol. 345, pp. 1153-8.

H. Shahmir, J. He, Z. Lu, M. Kawasaki, and T. G. Langdon: Mater. Sci. Eng. A, 2016, vol. 676, pp. 294-303.

Z. Li, L. Fu, B. Fu, and A. Shan: Mater. Sci. Eng. A, 2012, vol. 558, pp. 309-318.

R.Z. Valiev: Nat. Mater., 2004, vol.3, pp. 511-516.

A. Azushima, R. Kopp, A. Korhonen, D. Y. Yang, F. Micari, G. D. Lahoti, P. Groche, J. Yanagimoto, N. Tsuji, A. Rosochowski and A. Yanagida: Cirp Ann - Manuf Techn., 2008, vol. 57, pp. 716-735.

A.P. Zhilyaev and T.G. Langdon: Prog. Mater. Sci., 2008, vol. 53, pp. 893-979.

R.K. Islamgaliev, R.Z. Valiev, and I.V. Alexandrov: Prog. Mater. Sci., 2000, vol. 45, pp. 103-189.

B. Schuh, F. Mendez-Martin, B. Völker, E. P. George, H. Clemens, R. Pippan and A. Ohenwarter: Acta Mater., 2015, vol. 96, pp. 258-68.

H. Shahmir, T. Mousavi, J. He, Z. Lu, M. Kawasaki, and T. G. Langdon, Mater. Sci. Eng. A, 2017, vol. 705, pp. 411-419.

G. D. Sathiaraj, P. P. Bhattacharjee, C.-W. Tsai, and J.-W. Yeh: Intermetallics, 2016, vol. 69, pp. 1-9.

G. D. Sathiaraj, M. Z. Ahmed, and P. P. Bhattacharjee: J. Alloys Compd., 2016, vol. 664, pp. 109-119.

Z. Wu, H. Bei, F. Otto, G. M. Pharr, and E. P. George: Intermetallics, 2014, vol. 46, pp. 131-140.

W. Zhou, L. M. Fu, P. Liu, X. D. Xu, B. Chen, G. Z. Zhu, X. D. Wang, A. D. Shan, and M. W. Chen: Intermetallics, 2017, vol. 85, pp. 90-97.

G. D. Sathiaraj, C. Lee, C. W. Tsai, J. W. Yeh, and P. P. Bhattacharjee: IOP Conf. Ser., 2015, vol. 82, p. 012068.

P. P. Bhattacharjee, G. D. Sathiaraj, M. Zaid, J. R. Gatti, C. Lee, C.-W. Tsai, and J.-W. Yeh: J. Alloys Compd., 2014, vol. 587, pp. 544-552.

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler, and E. P. George: J. Alloys Compd., 2015, vol. 623, pp. 348-353.

G. D. Sathiaraj and P. P. Bhattacharjee: J. Alloys Compd., 2015, vol. 647, pp. 82-96.

M. Komarasamy, N. Kumar, Z. Tang, R. S. Mishra, and P. K. Liaw: Mater. Res. Lett., 2014, vol. 3, pp. 30-34.

I. S. Wani, T. Bhattacharjee, S. Sheikh, Y. P. Lu, S. Chatterjee, P. P. Bhattacharjee, S. Guo, and N. Tsuji: Mater. Res. Lett., 2016, vol. 4, pp. 174-179.

N. D. Stepanov, D. G. Shaysultanov, M. S. Ozerov, S. V. Zherebtsov, and G. A. Salishchev: Mater. Lett., 2016, vol. 185, pp. 1-4.

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov, and G. Salishchev: Intermetallics, 2015, vol. 59, pp. 8-17.

N. Park, I. Watanabe, D. Terada, Y. Yokoyama, P. K. Liaw, and N. Tsuji: Metall. Trans. A, 2014, vol. 46, pp. 1481-1487.

S. J. Sun, Y. Z. Tian, H. R. Lin, X. G. Dong, Y. H. Wang, Z. J. Zhang, and Z. F. Zhang: Mater. Des., 2017, vol. 133, pp. 122-127.

T. Ungár: Scr. Mater., 2004, vol. 51, pp. 777-781.

A. Stukowski, J. Markmann, J. Weissmüller, and K. Albe: Acta Mater., 2009, vol. 57, pp. 1648-1654.

G. D. Sathiaraj and P. P. Bhattacharjee: Mater. Charact., 2015, vol. 109, pp. 189-197.

F. Otto, A. Dlouhý, K. G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler and E. P. George: Acta Mater., 2016, vol. 112, pp. 40-52.

E. J. Pickering, R. Muñoz-Moreno, H. J. Stone and N. G. Jones: Scr. Mater., 2016, vol. 113, pp. 106-109.

Y. Sun, S. Xu, and A. Shan: Mater. Sci. Eng. A, 2015, vol. 641, pp. 181-188.

Y. H Zhao, X. Z Liao, S. Cheng, E. Ma, and Y. T Zhu: Adv Mater., 2006, vol. 18, pp. 2280-2283.

R. Valiev,A.V.Sergueeva, and A.K.Mukherjee: Scr. Mater., 2003, vol. 49, pp. 669-674.

W. H. Liu, Y. Wu, J. Y. He, T. G. Nieh, and Z. P. Lu: Scr. Mater., 2013, vol. 68, pp. 526-529.

A. R. Kalidindi, T. Chookajorn and C. A. Schuh: Jom, 2015, vol. 67, pp. 2834-2843.

C.E.Krill, A.Michels, H.Ehrhardt,R.Birringer and D.T.Wu: Adv Mater., 1999, vol. 47, pp. 2143-2152.

N. Zhou, T. Hu, J. Huang and J. Luo: Scr. Mater., 2016, vol. 124, pp. 160-163.

N. Zhou, T. Hu, and J. Luo: Curr. Opin. Solid State Mater. Sci., 2016, vol. 20, pp. 268-277.

P.-K. Huang and J.-W. Yeh: Scr. Mater., 2010, vol. 62, pp. 105-108.

K. Y. Tsai, M. H. Tsai, and J. W. Yeh: Acta. Mater., 2013, vol. 61, pp. 4887-4897.

J. Dąbrowa, W. Kucza, G. Cieślak, T. Kulik, M. Danielewski, and J.-W. Yeh: J. Alloys Compd., 2016, vol. 674, pp. 455-462.

J.Kallqvist, M.Schwind, J.O.Nilsson,J.Agren,and H.O.Andren: Acta.Mater.,2000, vol. 48, pp. 24773-2481.

F. Zhang, C. Zhang, S. L. Chen, J. Zhu, W. S. Cao, and U. R. Kattner: Calphad, 2014, vol. 45, pp. 1-10.

F. Otto, Y. Yang, H. Bei and E. P. George: Acta Mater.,2013, vol. 61, pp. 2628-2638.

F.J.Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier, Kidlington, Oxford OX5 1GB, UK, 2004, pp. 169–72.

I.T Caraballo and P. E. Castillo: Acta Mater., 2015, vol. 85, pp. 14-23.

Q. Wei, S. Cheng, K. T. Ramesh, and E. Ma: Mater. Sci. Eng. A, 2004, vol. 381, pp. 71-79.

S. Gangireddy, L. Kaimiao, B. Gwalani and R. S.Mishra: Mater. Sci. Eng. A, 2018, vol. 727, pp. 148-159.

S. Gangireddy, B. Gwalani, K. Liu, R. Banerjee and R. S. Mishra: Mater. Sci. Eng. A, 2018, vol. 734, pp. 42-50.

S. Gangireddy, B. Gwalani and R. S. Mishra: Mater. Sci. Eng. A, 2018, vol. 736, pp. 344-348.

G. Laplanche, A. Kostka, O. M. Horst, G. Eggeler and E. P. George, Acta Mater., 2016, vol. 118, pp. 152-163.

M.Furukawa, Z.Horita, M.Nemoto, A.J.Barenes and T.G.Langdon, Acta Mater., 2000, vol. 48, pp. 3633-3640.

H. Shahmir, J. He, Z. Lu, M. Kawasaki, and T. G. Langdon: Mater. Sci. Eng. A, 2017, vol. 685, pp. 342-348.

D. G. Shaysultanov, N. D. Stepanov, A. V. Kuznetsov, G. A. Salishchev and O. N. Senkov: Jom, 2013, vol. 65, pp. 1815-1828.

J-W. Qiao, Y. Zhang and P. K. Liaw: J. Iron. Steel. Res. Int., 2016, vol. 23, pp. 2-6.

R. Carroll, C. Lee, C. W. Tsai, J. W. Yeh, J. Antonaglia, B. A. Brinkman, M. LeBlanc, X. Xie, S. Chen, P. K. Liaw and K. A. Dahmen, Sci. rep., 2015, vol. 5, p. 16997.

Z. Li, L.Zhang, N. Sun, L. Fu and A. Shan:Mater. Lett., 2015, vol. 150, pp. 108-110.

Y. Zhang, J. P. Liu, S. Y. Chen, X. Xie, P. K. Liaw, K. A. Dahmen, J. W. Qiao and Y. L. Wang: Pro. Mater. Sci., 2017, vol. 90, pp. 358-460.

J. Y. He, C. Zhu, D. Q. Zhou, W. H. Liu, T. G. Nieh and Z. P. Lu: Intermetallics, 2014, vol. 55, pp. 9-14.

Acknowledgments

This research was financially supported by National Major Science and Technology Project of China (No. 2014ZX07214-002). The authors (X.P.D) would like to acknowledge financial support from National Natural Science Foundation of China (Grant No. 51501114); Science and Technology Committee of Shanghai Municipality (Grant No. 15YF1406600).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 8, 2018.

Rights and permissions

About this article

Cite this article

Li, Z., Fu, L., Zheng, H. et al. Effect of Annealing Temperature on Microstructure and Mechanical Properties of a Severe Cold-Rolled FeCoCrNiMn High-Entropy Alloy. Metall Mater Trans A 50, 3223–3237 (2019). https://doi.org/10.1007/s11661-019-05231-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05231-y