Abstract

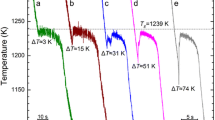

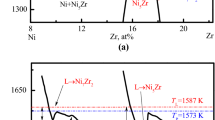

In contrast to the classical eutectic growth models, according to which the eutectic spacing decreases invariably with undercooling, an anomalous transition from fine to coarse lamellar eutectics was found in the undercooled Ni-29.8 at. pct Si eutectic alloy. In this study, the growth kinetics, recalescence processes, and grain orientations were analyzed. A sharp increase of the growth velocity at an undercooling of about 100 K was found. The recalescence front transited in sequence from a diffuse one with tips, to a diffuse one without tips and then to a sharp one. The microstructures changed from a mixture of directional rod-shaped γ-Ni31Si12 grains and fine lamellar eutectics to solely coarse lamellar eutectics. Coarse lamellar eutectics were found to be formed by rapid solidification of primary directional rod-shaped Ni31Si12 intermetallic compound and subsequent epitaxial growth of secondary Ni2Si intermetallic compound, being consistent with the predictions of eutectic–dendritic and dendritic growth models. Coarse anomalous eutectics at low undercooling were formed by fragmentation of fine lamellar eutectics and their subsequent coarsening. At high undercooling, they were formed by decoupled-eutectic growth.

Similar content being viewed by others

Notes

For lamellar eutectics, λ is the lamellar spacing, while for rod eutectics, λ is the sum of the radiuses of constituent phases.

For both the Ni-19.6 at. pct P and Ni-29.8 at. pct Si eutectic alloys, the constituent eutectic phases are two stoichiometric intermetallic compounds. In this case, solute supersaturation is completely absent to avoid the chemical superheating effect.

Generally, the recalescence events can be used to understand the solidification processes, e.g., one recalescence event usually corresponds to one solidification process. This is, however, not the case if multiple nucleation events happen within the sample or epitaxial growth of the second phase on the primary phase occurs, e.g., in current work.

It should be pointed out that except for Figure 2, other SEM images from different positions of the samples were used to measure the lamellar spacing and the width of the primary rod-shaped γ-Ni31Si12 grains. At least 30 measurements were carried out to obtain a reliable average value with the help of the software of ImageJ.

It should be pointed out that the widths of the primary γ-Ni31Si12 grains and the secondary δ-Ni2Si do not deviate from each other significantly; see e.g., Figure 7.

Similar results can be found in the undercooled Ag-Cu eutectic alloys,[23] i.e., coarse anomalous eutectics distribute around the primary lamellar eutectics.

References

W. Kurz, D.J. Fisher: Inter. Mater. Rev., 1979, vol. 24, pp. 177-204.

Y.P. Lu, Y. Dong, S. Guo, L. Jiang, H.J. Kang, T.M. Wang, B. Wen, Z.J. Wang, J.C. Jie, Z.Q. Cao, H.H. Ruan, T.J. Li: Sci. Rep., 2014, vol. 4, pp. 6200.

Y.P. Lu, X.Z. Gao, L. Jiang, Z.N. Chen, T.M. Wang, J.C. Jie, H.J. Kang, Y.B. Zhang, S. Guo, H.H. Ruan, Y.H. Zhao, Z.Q. Cao, T.J. Li: Acta Mater., 2017, vol. 124, pp. 143-150.

D.M. Herlach: Mater. Sci. Eng. R., 1994, vol. 12, pp. 177-272.

K.A. Jackson, J.D. Hunt: Trans. AIME., 1966, vol. 236, pp. 1129-1142.

R. Trivedi, P. Magnin, W. Kurz: Acta Metall., 1987, vol. 35, pp. 971-980.

N. Wang, Y.E. Kalay, R. Trivedi: Acta Mater., 2011, vol. 59, pp. 6604-6619.

R. Trivedi, N. Wang: Acta Mater., 2012, vol. 60, pp. 3140-3152.

H.L. Huang, C.L. Yang, Q.J. Song, K. Ye, F. Liu: J. Appl. Phys., 2016, vol. 120, pp. 043905.

J.F. Li, Y.H. Zhou: Acta Mater., 2005, vol. 53, pp. 2351-2359.

L. Liu, J.F. Li, Y.H. Zhou: Acta Mater., 2009, vol. 57, pp. 1536-1545.

X.X. Wei, X. Lin, W. Xu, Q.S. Huang, M. Ferry, J.F. Li, Y.H. Zhou: Acta Mater., 2015, vol. 95, pp. 44-56.

M. Schwarz, A. Karma, K. Eckler, D.M. Herlach: Phys. Rev. Lett., 1994, vol. 73, pp. 1380-1383.

A. Karma: Inter. J. Non-Equilibrium Process., 1998, vol. 11, pp. 201-233.

H.F. Wang, F. Liu, Y.M. Tan: Acta Mater., 2011, vol. 59, pp. 4787-4797.

R. Goetzinger, M. Barth, D.M. Herlach: Acta Mater., 1998, vol. 46, pp. 1647-1655.

B.B. Wei, G.C. Yang, Y.H. Zhou: Acta Metall. Mater., 1991, vol. 39, pp. 1249-1258.

M.J. Li, K. Nagashio, T. Ishikawa, S. Yoda, K. Kuribayashi: Acta Mater., 2005, vol. 53, pp. 731–741.

J.F. Li, W.Q. Jie, S. Zhao, Y.H. Zhou: Metall. Mater. Trans. A, 2007, vol. 38, pp. 1806-1816.

C. Yang, J. Gao, Y.K. Zhang, M. Kolbe, D.M. Herlach: Acta Mater., 2011, vol. 59, pp. 3915-3926.

X. Lin, Y.Q. Cao, Z.T. Wang, J. Cao, L.L. Wang, W.D. Huang: Acta Mater., 2017, vol. 126, pp. 210-220.

C.R. Clopet, R.F. Cochrane, A.M. Mullis: Acta Mater., 2013, vol. 61, pp. 6894-6902.

A.M. Mullis, C.R. Clopet: Acta Mater., 2018, vol. 145, pp. 186-195.

M.J. Li, K. Nagashio, T. Ishikawa, A. Mizuno, M. Adachi, M. Watanabe, S. Yoda, K. Kuribayashi, Y. Katayama: Acta Mater., 2007, vol. 56, pp. 2514-2525.

Y.K. Zhang, J. Gao, M. Kolbe, S. Klein, C. Yang, H. Yasuda, D.M. Herlach, C.A. Gandin: Acta Mater., 2013, vol. 61, pp. 4861-4873.

Y.P. Lu, X. Lin, G.C. Yang, J.J. Li, Y.H. Zhou: J. Appl. Phys., 2008, vol. 104, pp. 013535.

F. Zhang, C. Lai, J.B. Zhang, Y.C. Zhang, Q. Zhou, H.F. Wang: J. Cryst. Growth., 2018, vol. 495, pp. 37-45.

H.F. Wang, F. Liu, D.M. Herlach: J. Cryst. Growth., 2014, vol. 389, pp. 68-73.

H.F. Wang, F. Liu, D.M. Herlach: J. Mater. Sci., 2015, vol. 50, pp. 176-188.

W.W. Kuang, H.F. Wang, F. Liu, S.L. Sobolev: J. Mater. Sci., 2016, vol. 51, pp. 2141-2152.

W.W. Kuang, C. Karrasch, H.F. Wang, F. Liu, D.M. Herlach: Scripta Mater., 2015, vol. 105, pp. 34-37.

H.F. Wang, F. Liu, D.M. Herlach: J. Mater. Sci., 2014, vol. 49, pp. 1537-1543.

H. Wang, D.M. Herlach, R.P. Liu: EPL., 2014, vol. 105, pp. 36001.

P. Nash, A. Nash: J. Phase Equilib., 1987, vol. 8, pp. 6-14.

Y. Du, J.C. Schuster: Metall. Mater. Trans. A, 1999, vol. 30, pp. 2409-2417.

J.C. Schuster, Y. Du: Metall. Mater. Trans. A, 2000, vol. 31, pp. 1795-1803.

E.G. Castle, A.M. Mullis, R.F. Cochrane: Acta Mater., 2014, vol. 66, pp. 378–387.

E.G. Castle, A.M. Mullis, R.F. Cochrane: Acta Mater., 2014, vol. 77, pp. 76–84.

H.F. Wang, F. Liu, G.C. Yang: J. Mater. Res., 2010, vol. 25, pp. 1963-1974.

A.K. Dahle, D.H.S. John, H.J. Thevik, L. Arnberg: Metall. Mater. Trans. B, 1999, vol. 30, pp. 287-293.

K. Dragnevski, A.M. Mullis, D.J. Walker, R.F. Cochrane: Acta Mater., 2002, vol. 50, pp. 3743-3755.

J. Svoboda, I. Turek, F.D. Fischer: Phil. Mag., 2005, vol. 85, pp. 3699-3707.

F.D. Fischer, J. Svoboda, H. Petryk: Acta Mater., 2014, vol. 67, pp. 1-20.

S. Li, J. Zhang, P. Wu: Metall. Mater. Trans. A, 2012, vol. 43, pp. 3748-3754.

S. Li, D.Y. Li, S.C. Liu, Z.H. Gu, W. Liu, J.W. Huang: Acta Mater., 2015, vol. 83, pp. 310-317.

P.K. Galenko, S. Reutzel, D.M. Herlach, D. Danilov, B. Nestler: Acta Mater., 2007, vol. 55, pp. 6834-6842.

P.K. Galenko, S. Reutzel, D.M. Herlach, S.G. Fries, I. Steinbach, M. Apel: Acta Mater., 2009, vol. 57, pp. 6166-6175.

M.J. Aziz, W.J. Boettinger: Acta Metall. Mater., 1994, vol. 42, pp. 527-537.

Acknowledgments

H.F. Wang would like to thank the Huo Yingdong Young Teacher Fund (No. 151048), the Aeronautical Science Foundation of China (No. 2015ZF53066), the Science Fund for Distinguished Young Scholars from Shaanxi province (2018-JC007), and the Fundamental Research Funds for the Central Universities and the support of Alexander von Humboldt Foundation for a research fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 24, 2018.

Rights and permissions

About this article

Cite this article

Zhang, F., Wang, H., Kolbe, M. et al. A Transition from Fine to Coarse Lamellar Eutectics in the Undercooled Ni-29.8 At. Pct Si Eutectic Alloy: Experiments and Modeling. Metall Mater Trans A 50, 2847–2859 (2019). https://doi.org/10.1007/s11661-019-05221-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05221-0