Abstract

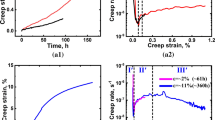

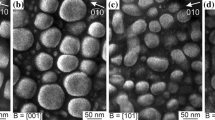

First-principles DFT methods are combined with an experimental approach to characterize the creep behavior of quinary Co-based L1\(_2\)-containing superalloys at elevated temperature conditions. Temperature-dependent SISF energies have been modeled, combining 0 K formation energies with vibrational free energy calculations to assess deformation mechanisms at finite temperature. Two different Co-Al-W alloys, containing the maximum possible amount of DFT-identified d-block alloying additions, were identified and cast as single crystals via the Bridgman process. Creep tests have been performed at two primary testing conditions, one at 900 \(^\circ \)C and the other at 982 \(^\circ \)C. Transmission scanning electron microscopy (TSEM) was performed at 30 kV in a scanning electron microscope to rapidly characterize the defect substructures. We observe a coupled APB/SISF/APB defect structure in Co-based superalloys at the low-temperature condition, similar to the defect structure observed in CoNi, in spite of containing no Ni. At 982 \(^\circ \)C, there is no evidence of faults and precipitates instead contain antiphase boundaries. The role of composition and temperature-dependent fault energies in the deformation process is addressed.

Reproduced with permission from Ref. [34]

Similar content being viewed by others

References

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida: Science, 2006, vol. 312, pp. 90-91.

M.S. Titus, A. Suzuki, and T.M. Pollock: Scr. Mater., 2012, vol. 66, pp. 574-577.

F. Xue, H.J. Zhou, X.H. Chen, H. Chang, M.L. Wang, and Q. Feng: Scr. Mater., 2015, vol. 97, pp. 37-40.

T.M. Pollock and A.S. Argon: Acta Metall. Mater., 1992, vol. 40, pp. 1-30.

M.S. Titus, Y.M. Eggeler, A. Suzuki, and T.M. Pollock: Acta Mater., 2015, vol. 82, pp. 530-539.

Y.M Eggler, M.S. Titus, A. Suzuki, and T.M. Pollock: Acta Mater., 2014, vol. 77, pp. 352-359.

R.C. Reed: The Superalloys: Fundamentals and Applications, 1st ed., Cambridge University Press, Cambridge, U.K., 2006, pp. 16-30.

R.C. Reed, N. Matan, D.C. Cox, M.A. Rist, and C.M.F. Rae: Acta Mater., 1999, vol. 47, pp. 3367-3381.

M.S. Titus, A. Mottura, R.K. Rhein, M.H. Chen, A. Van der Ven, and T.M. Pollock: Beyond Nickel-Based Superalloys: Conference Proceedings, ECI Digital Archives, 2016.

G. Kresse and J. Hafner: Phys. Rev. B, 1993, vol. 47, pp. 558-561.

G. Kresse and J. Furthmüller: Comput. Mater. Sci., 1996, vol. 6, pp. 15-50.

G. Kresse and D. Joubert: Phys. Rev. B, 1999, vol. 59, pp. 1758-1775.

J.P Perdew, K. Burke, and M. Ernzerhof: Phys. Rev. Lett., 1996, vol. 77, pp. 3865-3868.

N. Ashcroft and N. Mermin: Solid State Physics, 1st ed., Brooks Cole, Pacific Grove, 1976.

S. Wei and M.Y. Chen: Phys. Rev. Lett., 1992, vol. 69, pp. 2799-2802.

M. Born: Dynamical Theory of Crystal Lattices, 1st ed., Clarendon Press, Wotton-under-Edge, UK, 1954.

E.A. Lass: Metall. Mater. Trans. A, 2017, vol. 48, pp. 2443-2459.

M. Tsunekane, A. Suzuki, and T.M. Pollock: Intermetallics, 2011, vol. 19, pp. 636-643.

A.J. Elliot, T.M. Pollock, S. Tin, W.T. King, S.-C. Huang, and M.F.X. Gigliotti: Met. Trans. A, 2004, vol. 35, pp. 3221-3231.

C.J. Humphreys: Ultramicroscopy, 1981, vol. 7, pp. 7-12.

P.G. Callahan, J.C. Stinville, E.R. Yao, M.P. Echlin, M.S. Titus, D.S. Gianola, M. De Graef, and T.M. Pollock: Ultramicroscopy, 2018, vol. 186, pp. 49-61.

D.J.H. Cockayne: J. Phys., Colloq., 1974, vol. 35, pp. 141-148.

A. Mottura, A. Janotti, and T.M. Pollock: Intermetallics, 2012, vol. 28, pp. 138-143.

C.A. Schneider, W.S. Rasband, and K.W. Eliceiri: Nat. Methods, 2012, vol. 9, pp. 671-675.

J.C. Yen, F.J. Chang, and S. Chang: IEEE Trans. on Image Process., 1995, vol. 4, pp. 370-378.

M. Sezgin and B. Sankur: J. of Elect. Imag., 2004, vol. 13, pp. 146-168.

K. Tanaka, M. Ooshima, N. Tsuno, A. Sato, and H. Inui: Philos. Mag., 2012, vol. 92, pp. 4011-4027.

A. Suzuki, H. Inui, and T.M. Pollock: Ann. Rev. Mater. Res., 2015, vol. 45, pp. 345-368.

F. Xue, C.H. Zenk, L.P. Freund, M. Hoelzel, S. Neumeier, and M. Göken: Scr. Mater., 2018, vol. 142, pp. 129-132.

K. Harris, G.L. Erickson, and R.E. Schwer: ASME 1983 International Gas Turbine Conference and Exhibit, 1983, vol. 5, pp. 1–11.

D.J. Frasier, J.R. Whetstone, K. Harris, G.L. Erickson, and R.E. Schwer: Proceedings of the Part II of Cost Conference, 1990, vol. 5, pp. 1281–90.

G.E. Fuchs: J. Mater. Eng. Perform., 2002, vol. 11, pp. 19-25.

M.G. Hebsur and R.V. Miner: NASA Tech. Mem. 88950, 1987, pp. 1-11.

Y.M. Eggeler, J. Müller, M.S. Titus, A. Suzuki, T.M. Pollock, and E. Spieker: Acta Mater., 2016, vol. 113, pp. 335-349.

K. Tanaka, T. Ohashi, K. Kishida, and H. Inui: Appl. Phys. Lett., 2007, vol. 91, p. 181907

B. Goodlet, L. Mills, B. Bales, M.A. Charpagne, S.P. Murray, W.C. Lenthe, L. Petzold, and T.M. Pollock: Metall. Mater. Trans. A, 2018, vol. 49, pp. 2324–2339.

M.S. Titus, R.K. Rhein, P.B. Wells, P.C. Dodge, G.B. Viswanathan, M.J. Mills, A. Van der Ven, and T.M. Pollock: Sci. Adv., 2016, vol. 2, e1601796.

S.K. Makineni, M. Lenz, P. Kontis, A. Kumar, P.J. Felfer, S. Neumeier, M. Herbig, E. Speicker, D. Raabe, and B. Gault: JOM, 2018, vol. 27, pp. 1–8.

S.M. Allen and J.W. Cahn: Acta Metall., 1979, vol. 27, pp. 1085-1095.

Acknowledgments

This research was supported by a Grant from the National Science Foundation (NSF-DMREF-1534264). Computational resource support was provided by the Center for Scientific Computing at the CNSI and MRL: an NSF MRSEC (DMR-1121053) and NSF CNS-0960316. We would like to thank Chris Torbet for his assistance in casting and machining of the specimens.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 14, 2018.

Rights and permissions

About this article

Cite this article

Rhein, R.K., Callahan, P.G., Murray, S.P. et al. Creep Behavior of Quinary γ′-Strengthened Co-Based Superalloys. Metall Mater Trans A 49, 4090–4098 (2018). https://doi.org/10.1007/s11661-018-4768-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4768-z