Abstract

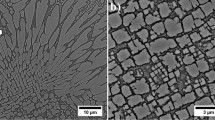

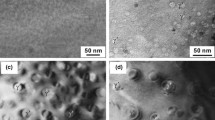

Cast-and-wrought heavily alloyed γ–γ′ nickel-based superalloys may exhibit large recovered grains inherited from the ingot conversion and characterized by a high density of close-to-coherent micrometric γ′ precipitates. In the AD730™ nickel-based superalloy, a previous work (Vernier et al. Scr Mater 153:10–13, 2018) highlighted a new interaction between such precipitates and a recrystallization front passing through. This interaction resulted in γ′ precipitates with a close-to-twin orientation relationship to their recrystallized host grain. Called T-type precipitates, they were revealed to be {111} bounded plate-like particles. The present paper aims to clarify the mechanism whereby such precipitates form. The formation of T-type precipitates actually is part of a more global mechanism which also produces γ′ precipitates slightly misoriented from their surrounding matrix (C-type precipitates) and of same size and morphology as T-type precipitates. Both T- and C-type precipitates display {111} facets and are evidenced in the AD730™, René65, and PER72 alloys, supporting the idea that the mechanism can more generally occur in all low-lattice-mismatch γ–γ′ nickel-based superalloys. Finally, a scenario is proposed: T/C-type precipitates form at the recrystallization front of grains sharing a 〈111〉 axis with the recovered grain they consume, and develop {111} facets and specific orientations which minimize the interfacial energy on both recrystallized and recovered sides.

Similar content being viewed by others

References

D. Furrer and H. Fecht: JOM, 1999, vol. 51, pp. 14–17.

R.C. Reed: The Superalloys, Fundamentals and Applications, Cambridge University Press, 2006.

R.W. Kozar, A. Suzuki, W.W. Milligan, J.J. Schirra, M.F. Savage, and T.M. Pollock: Metall. Mater. Trans. A, 2009, vol. 40, pp. 1588–603.

P.A. Manohar and F. Chandra: ISIJ Int., 1998, vol. 38, pp. 913–24.

F.C. Campbell: Elements of Metallurgy and Engineering Alloys, ASM International, Materials Park, 2008.

G.S. Rohrer: J. Mater. Sci., 2011, 46, pp. 5881–95.

V. Randle and B. Ralph: Acta Metall., 1986, vol. 34, pp. 891–8.

R.D. Doherty: Met. Sci., 1982, vol. 16, pp. 1–13.

E. Nes, N. Ryum, and O. Hunderi: Acta Metall., 1985, vol. 33, pp. 11–22.

R.W. Cahn and P. Haasen: Physical Metallurgy, Volume I, North Holland, Amsterdam, 1996.

A. Porter and B. Ralph: J. Mater. Sci., 1981, vol. 16, pp. 707–13.

M.A. Charpagne, P. Vennéguès, T. Billot, J.M. Franchet, and N. Bozzolo: J. Microsc., 2016, vol. 263, pp. 106–12.

M. Charpagne, T. Billot, J. Franchet, and N. Bozzolo: Superalloys 2016, 2016, pp. 417–26.

M.A. Charpagne, T. Billot, J.M. Franchet, and N. Bozzolo: J. Alloys Compd., 2016, vol. 688, pp. 685–94.

B.J. Bond, C.M.O. Brien, J.L. Russell, J.A. Heaney, and M.L. Lasonde: 8th International Symposium on Superalloy 718 Derivatives, 2014, pp. 107–18.

R.S. Minisandram, L.A. Jackman, J.L. Russell, M.L. Lasonde, J.A. Heaney, and A.M. Powell: 8th International Symposium on Superalloy 718 Derivatives, 2014, pp. 95–105.

C. Crozet, A. Devaux, R. Forestier, S. Charmond, M. Hueller, D. Helm, and W. Buchmann: Superalloys 2016 Proceedings of the 13th International Symposium on Superalloys, 2016, pp. 437–46.

S. Vernier, J.-M. Franchet, C. Dumont, P. Vennéguès, and N. Bozzolo: Scr. Mater., 2018, vol. 153, pp. 10–13.

D.G. Brandon: Acta Metall., 1966, vol. 14, pp. 1479–84.

R.A. Ricks, A.J. Porter, and R.C. Ecob: Acta Metall., 1983, vol. 31, pp. 43–53.

G. Nolze and R. Hielscher: J. Appl. Crystallogr., 2016, vol. 49, pp. 1786–1802.

J. Humphreys, G.S. Rohrer, and A. Rollett: Recrystallization and Related Annealing Phenomena, 3rd edn., Elsevier Ltd, New York, 2017.

Y. Huang and F.J. Humphreys: Mater. Chem. Phys., 2012, vol. 132, pp. 166–74.

D.L. Olmsted, S.M. Foiles, and E.A. Holm: Acta Mater., 2009, vol. 57, pp. 3694–703.

A.G. Khachaturyan, S. V. Semenovskaya, and J.W. Morris: Acta Metall., 1988, vol. 36, pp. 1563–72.

S.J. Yeom, D.Y. Yoon, and M.F. Henry: Metall. Mater. Trans. A, 1993, vol. 24A, pp. 1975–81.

B.B. Straumal, O.A. Kogtenkova, A.S. Gornakova, V.G. Sursaeva, and B. Baretzky: J. Mater. Sci., 2015, vol. 51, pp. 382–404.

B.B. Straumal, S.A. Polyakov, E. Bischoff, W. Gust, and E.J. Mittemeijer: Interface Sci., 2001, vol. 9, pp. 287–92.

S.P. Ringer, W.B. Li, and K.E. Easterling: Acta Metall., 1989, vol. 37, pp. 831–41.

R.W. Balluffi: Phys. Status Solidi, 1970, vol. 11, pp. 11–34.

A. Devaux, B. Picqué, M.F. Gervais, E. Georges, T. Poulain, and P. Héritier: Superalloys 2012, 2012, pp. 911–19.

H. Grimmer, W. Bollmann, and D.H. Warrington: Acta Crystallogr. Sect. A, 1974, vol. 30, pp. 197–207.

Acknowledgment

The authors would like to acknowledge the financial support of the ANR-Safran industrial chair OPALE.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 10, 2018.

Rights and permissions

About this article

Cite this article

Vernier, S., Franchet, JM., Dumont, C. et al. A Mechanism Leading to γ′ Precipitates with {111} Facets and Unusual Orientation Relationships to the Matrix in γ–γ′ Nickel-Based Superalloys. Metall Mater Trans A 49, 4308–4323 (2018). https://doi.org/10.1007/s11661-018-4734-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4734-9