Abstract

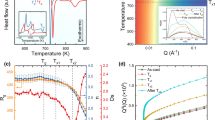

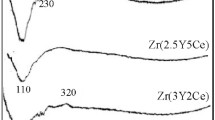

The current study examines the evolution of nanocrystallites of ZrO2 with time and temperature in a Fe-ZrO2 composite. The crystallite sizes were determined through X-ray peak broadening analysis by the Williamson–Hall method together with dark field transmission electron microscopy. The ZrO2 crystallites were found to be stable and retained their sizes at 973 K and 1073 K for hold durations up to 600 minutes. On the other hand, the crystallites were seen to grow at 1173 K and reached up to ~ 200 nm for a hold time of 600 minutes. The Ostwald ripening model was adopted to understand crystallite growth while a dislocation-driven pipe diffusion was adopted for understanding the kinetics of grain growth. The activation energy of grain growth was calculated as ~ 379 kJ mol−1. The modeled and experimentally calculated size evolutions with time and temperature were shown to be in good agreement with each other. A detailed discussion on the kinetics and activation energy of grain growth of ZrO2 crystallites in a Fe matrix is presented in this manuscript.

Similar content being viewed by others

References

G. K. Rane, U. Welzel and E. J. Mittemeijer, Acta Materialia 2012, vol. 60, pp. 7011-7023.

R. A. Andrievski, Journal of Materials Science 2014, vol. 49, pp. 1449-1460.

3.C. Suryanarayana, Bull. Mater. Sci., 1994, vol. 17, pp. 307-346.

4.B. S. Murty, M. K. Datta and S. K. Pabi, Sadhana, 2003, vol. 28, pp. 23-45.

Mostafa Saber, Carl C. Koch and Ronald O. Scattergood, Materials Research Letters 2015, vol. 3, pp. 65-75.

6.CC Koch, RO Scattergood, M Saber, H Kotan, J. Mater. Res. 2013, vol. 28, pp. 1785-1791.

H. R. Peng, M. M. Gong, Y. Z. Chen and F. Liu, International materials reviews 2017, vol. 62, pp. 303-333.

Suveen N. Mathaudhu and Brad L. Boyce, JOM 2015, vol. 67, pp. 2785-2787.

Shigeharu Ukai, Toshio Nishida, Hirokazu Okada, Takanari Okuda, Masayuki Fujiwara and Kazutaka Asabe, Journal of Nuclear Science and Technology 1997, vol. 34, pp. 256-263.

Shigeharu Ukai and Masayuki Fujiwara, Journal of Nuclear Materials 2002, vol. 307–311, Part 1, pp. 749-757.

S. Ukai, S. Ohtsuka, T. Kaito, H. Sakasegawa, N. Chikata, S. Hayashi and S. Ohnuki, Materials Science and Engineering: A 2009, vol. 510–511, pp. 115-120.

Somayeh Pasebani, Indrajit Charit, Darryl P. Butt and James I. Cole, Journal of Nuclear Materials 2013, vol. 434, pp. 282-286.

Jan Hoffmann, Michael Rieth, Rainer Lindau, Michael Klimenkov, Anton Möslang and Hugo Ricardo Zschommler Sandim, Journal of Nuclear Materials 2013, vol. 442, pp. 444-448.

14. K. G. Raghavendra, A Dasgupta, P Bhaskar, K. Jayasankar, C. N. Athreya, P Panda, S. Saroja, V. SubramanyaSarma and R. Ramaseshan, Powder Technol. 2016, vol. 287, pp. 190-200.

L.R. Curwick, Y.G. Kim, and H.F. Merrick: The International Nickel Company, Inc. Paul D. Merica Research Laboratory and NASA-Lewis Research Center, 1977

R. Le Pierres, S.J. Dewson, X. Li: in ICAPP ’06 (2006).

B. A. Wang, N. Wang, Y. J. Yang, H. Zhong, M. Z. Ma, X. Y. Zhang and R. P. Liu, Materials Science and Engineering: A 2017, vol. 692, pp. 168-173.

W. Z. Xu, L. L. Li, M. Saber, C. C. Koch, Y. T. Zhu and R. O. Scattergood, Journal of Nuclear Materials 2014, vol. 452, pp. 434-439.

Mostafa Saber, Hasan Kotan, Carl C. Koch and Ronald O. Scattergood, Materials Science and Engineering: A 2012, vol. 556, pp. 664-670.

S. C. Axtell and R. Schalek, Journal of Applied Physics 1996, vol. 79, pp. 5263-5265.

Pushkar Jha, Pallav Gupta, Devendra Kumar and Om Parkash, Journal of Composite Materials 2014, vol. 48, pp. 2107-2115.

Joel Hemanth, Materials Science and Engineering: A 2009, vol. 507, pp. 110-113.

Zbigniew Oksiuta, Pawel Kozikowski, Malgorzata Lewandowska, Masato Ohnuma, Koppoju Suresh and Krzysztof J. Kurzydlowski, Journal of Materials Science 2013, vol. 48, pp. 4620-4625.

24. X Mao, TK Kim, SS Kim, KH Oh, J Jang. J. Nucl. Mater. 2012, vol. 428, pp. 82-89.

25. P. Krautwasser, M. Widera, D. Esser, BD Wirth, D Sporer, High Temp. High Press. 1994, vol. 26, pp. 549-560.

S. Y. Zhong, J. Ribis, V. Klosek, Y. de Carlan, N. Lochet, V. Ji and M. H. Mathon, Journal of Nuclear Materials 2012, vol. 428, pp. 154-159.

N. H. Oono, S. Ukai, S. Hayashi, S. Ohtsuka, T. Kaito, A. Kimura, T. Torimaru and K. Sakamoto, Journal of Nuclear Materials 2017, vol. 493, pp. 180-188.

N. Oono, K. Nakamura, S. Ukai, T. Kaito, T. Torimaru, A. Kimura and S. Hayashi, Nuclear Materials and Energy 2016, vol. 9, pp. 342-345.

Tong Liu, Hailong Shen, Chenxi Wang and Wusheng Chou, Progress in Natural Science: Materials International 2013, vol. 23, pp. 434-439.

P.K. Parida, A. Dasgupta, K.G. Raghavendra, S. Chakravarty, K. Jayasankar, and S. Saibaba: in European Microscopy Congress 2016: Proceedings, Wiley, 2016.

31 PK Parida, A Dasgupta, K. Jayasankar, M. Kamruddin and S. Saroja, Journal of Nuclear Materials 2013, vol. 441, pp. 331-336.

S. Takaki Y. Kimura, S. Suejima, R. Uemor, H. Tamehiro, ISIJ International 1999, vol. 39 pp. 176-182.

Lei Dai, Yongchang Liu and Zhizhong Dong, Powder Technology 2012, vol. 217, pp. 281-287.

C. Heintze, M. Hernández-Mayoral, A. Ulbricht, F. Bergner, A. Shariq, T. Weissgärber and H. Frielinghaus, Journal of Nuclear Materials 2012, vol. 428, pp. 139-146.

J. K. L. Lai, C. H. Shek and G. M. Lin, Scripta Materialia 2003, vol. 49, pp. 441-446.

Z.W. Chen, C.H. Shek and J.K.L. Lai, Appl. Phys. A 2005, vol. 80, pp. 703-707.

H. Natter, M. Schmelzer, M. S. Löffler, C. E. Krill, A. Fitch and R. Hempelmann, The Journal of Physical Chemistry B 2000, vol. 104, pp. 2467-2476.

C. Suryanarayana and M. Grant Norton: X-Ray Diffraction—A Practical Approach, Springer US, 1998.

Shou-Gang Chen, Yan-Sheng Yin, Dao-Ping Wang and Jia Li, Journal of Crystal Growth 2004, vol. 267, pp. 100-109.

40.A. Baldan: J. Mater. Sci., 2002, vol. 37, pp. 2171-2202.

M. J. Mayo, International materials reviews 1996, vol. 41, pp. 85-115.

C.C. Koch, I.A. Ovid’ko, S. Seal, and S. Veprek: Structural Nanocrystalline Materials: Fundamentals and Applications, Cambridge University Press, 2007.

T. G. Nieh and J. Wadsworth, Acta Metallurgica et Materialia 1990, vol. 38, pp. 1121-1133.

Anne P. Hynes, Robert H. Doremus and Richard W. Siegel, Journal of the American Ceramic Society 2002, vol. 85, pp. 1979-1987.

Rachman Chaim, Amit Shlayer and Claude Estournes, Journal of the European Ceramic Society 2009, vol. 29, pp. 91-98.

46. K.G. Raghavendra, A. Dasgupta, C. Ghosh, K. Jayasankar, V. Srihari, S. Saroja, Powder Technol. 2018, Vol 327, pp. 267-274

Acknowledgements

The authors thank Dr. A.K. Bhaduri, Director of IGCAR, and Dr. G Amarendra, Director of MMG, for their constant support and encouragement during the course of this work. The authors gratefully acknowledge the experimental support provided by the UGC DAE CSR Kalpakkam node for the SEM facility. One of the authors (RKG) acknowledges DAE, India, for the fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 8, 2017.

Rights and permissions

About this article

Cite this article

Raghavendra, K.G., Dasgupta, A., Athreya, C.N. et al. Microstructural Evolution of Nanocrystalline ZrO2 in a Fe Matrix During High-Temperature Exposure. Metall Mater Trans A 49, 3565–3574 (2018). https://doi.org/10.1007/s11661-018-4715-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4715-z