Abstract

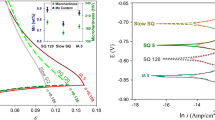

Electron work function (EWF) is correlated to intrinsic properties of metallic materials and can be an alternative parameter to obtain supplementary clues for guiding material design and modification. A higher EWF corresponds to a more stable electronic state, leading to higher resistance to any attempt to change the material structure and properties. In this study, effects of Ni as a solute with a higher EWF on mechanical, electrochemical, and tribological properties of low-carbon steel were investigated. Added Ni, which has more valence electrons, enhanced the electrons-nuclei interaction in the steel, corresponding to higher EWF. As a result, the Ni-added steel showed increased mechanical strength and corrosion resistance, resulting in higher resistances to wear and corrosive wear. Mechanism for the improvements is elucidated through analyzing EWF-related variations in Young’s modulus, hardness, corrosion potential, and tribological behavior.

Similar content being viewed by others

References

W. Li, D.Y. Li: Wear, 2003, vol. 255, pp. 333-340.

H. Fu, Q. Xiao, J. Kuang, Z. Jiang, J. Xing: Mater. Sci. Eng. A, 2007, vol. 466, pp. 160-165.

K. Van Acker, D. Vanhoyweghen, R. Persoons, J. Vangrunderbeek: Wear, 2005, vol. 258, pp. 194-202.

Y. Sun, T. Bell: Mater. Sci. Eng. A, 1991, vol. 140, pp. 419-434.

A. Leyland, A. Matthews: Wear, 2000, vol. 246, p. 1-11.

B. Podgornik, B. Žužek, F. Kafexhiu, V. Leskovšek: Tribol. Lett., 2016, vol. 63, pp. 1-10.

L. Li, D.Y. Li: Wear, 2013, vol. 301, pp. 70-75.

X.H. Tang, L. Li, B. Hinckley, K. Dolman, L. Parent, D.Y. Li: Tribol. Lett., 2015, vol. 58, pp. 1-10.

J. Cui, H. Guo, J.W. Li, D.Y. Li, L. Parent, H. Tian: Tribol. Lett., 2016, vol. 103, pp. 432-439.

M. Filipovic, Z. Kamberovic, M. Korac, M. Gavrilovski: Met. Mater. Int, 2013, vol. 19, pp. 473-481.

S. Halas: Mater. Sci-Pol., 2006, vol. 24, pp. 952-966.

N.D. Lang, W. Kohn: Phys. Rev. B, 1971, vol. 3 pp. 1215-1223.

G.V. Samsonov, V.S. Fomenko, I.A. Podchernyaeva, L.N. Okhremchuk: Sov. Powder Metall. Met. Ceram. 1974, vol. 13, pp. 836-842.

G. Hua, D. Li: Appl. Phys. Lett., 2011, vol. 99, pp. 041907.

G.M. Hua, D.Y. Li: Phys. Status Solidi B, 2012, vol. 249 pp. 1517-1520.

H. Lu, D. Li: Phys. Status Solidi B, 2014, vol. 251, pp. 815-820.

H. Lu, G. Hua, D. Li: Appl. Phys. Lett., 2013, vol. 103 pp. 261902.

H. Lu, X. Huang, D. Li: J. Appl. Phys, 2014, vol. 116, pp. 173506.

H. Lu, Z. Liu, X. Yan, D. Li, L. Parent, H. Tian: Sci. Rep., 2016, vol. 6, pp. 24366.

Y. Li, D.Y. Li: J. Appl. Phys, 2004, vol. 95 pp. 7961.

J. Krim, C. Daly, A. Dayo: Tribol. Lett, 1995, vol. 1, pp. 211-218.

S. Liu, H. Lu, D.Y. Li: Appl. Surf. Sci., 2015, vol. 351, pp. 316-319.

Y. Li, D.Y. Li: Wear, 2005, vol. 259, pp. 1432-1436.

A.L. Zharin, D.A. Rigney: Tribol. Lett., 1998, vol. 4, pp. 205-213.

X.C. Huang, H. Lu, D.Y. Li: Mater. Chem. Phys, 2016, vol. 173, pp. 238-245.

C. Oernek, D.L. Engelberg: J. Mater. Sci., 2016, vol. 51, pp. 1931-1948.

W. Li, D.Y. Li: Surf. Rev. Lett., 2004, vol. 11, pp. 173-178.

Z.Yang, H. Lu, Z. Liu, X. Yan, D. Li: RSC Adv., 2016, vol. 6 pp. 18793-18799.

S.S. Sohn, S.Y. Han, S.Y. Shin, J. Bae, S. Lee: Met. Mater. Int., 2013, vol. 19 pp. 423-431.

C.Y. Tang, D.Y. Li, G.W. Wen: Tribol. Lett., 2011, vol. 41, pp. 569-572.

L. Yue, H. Zhang, D.Y. Li: Scripta Mater., 2010, vol. 63, pp.1116-1119.

D. Zhu, H. Zhang, D. Y. Li: J Appl. Phys., 2011, vol. 110, pp.124911.

W. Li, D.Y. Li: Mater. Sci. Technol., 2002. vol. 18, pp. 1057-1060.

W. Li, Y. Wang, D.Y. Li: Phys. Status Solidi A, 2004, vol. 201 pp. 2005-2012.

W. Li, D.Y. Li: J Appl. Phys, 2006, vol. 99, pp. 073502.

H.B. Michaelson: J. Appl. Phys., 1977, vol. 48 pp. 4729-4733.

K. L. Johnson: Contact Mechanics, Cambridge University Press, Cambridge, UK, 1985.

S. Halas, T. Durakiewicz: J. Phys. Condens. Matter., 1999, vol. 10, pp. 10815.

E. Rabinowicz: Friction and wear of materials, Wiley, New York, NY, 1965.

M. Methfessel, D. Hennig, M. Scheffler: Phys. Rev. B, 1992, vol. 46, pp. 4816-4829.

S. Mosleh-Shirazi, G. Hua, F. Akhlaghi, X. Yan, D. Li: Sci. Rep., 2015, vol. 5, pp. 18154.

Acknowledgments

The authors are grateful for financial support from the Natural Science and Engineering Research Council of Canada, Suncor Energy, GIW Industries Inc., Camber Technology Corporation, Shell Canada Ltd., Magna International Inc. and Volant Products Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 23, 2017.

Rights and permissions

About this article

Cite this article

Lu, H., Huang, X., Hou, R. et al. Understanding the Effect of Ni on Mechanical and Wear Properties of Low-Carbon Steel from a View-Point of Electron Work Function. Metall Mater Trans A 49, 2612–2621 (2018). https://doi.org/10.1007/s11661-018-4616-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4616-1