Abstract

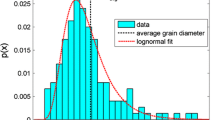

We use high-energy X-ray diffraction microscopy (HEDM) to characterize the microstructure of Ni-base alloy 725. HEDM is a non-destructive technique capable of providing three-dimensional reconstructions of grain shapes and orientations in polycrystals. The present analysis yields the grain size distribution in alloy 725 as well as the grain boundary character distribution (GBCD) as a function of lattice misorientation and boundary plane normal orientation. We find that the GBCD of Ni-base alloy 725 is similar to that previously determined in pure Ni and other fcc-base metals. We find an elevated density of Σ9 and Σ3 grain boundaries. We also observe a preponderance of grain boundaries along low-index planes, with those along (1 1 1) planes being the most common, even after Σ3 twins have been excluded from the analysis.

Similar content being viewed by others

References

J. E. Burke and D. Turnbull, Prog Met Phys 1952, vol. 3, pp. 220-292.

E. O. Hall, P Phys Soc Lond B 1951, vol. 64, pp. 747-753.

N. J. Petch, J Iron Steel I 1953, vol. 174, pp. 25-28.

3. T. Watanabe and S. Tsurekawa, Mat Sci Eng a-Struct 2004, vol. 387, pp. 447-455.

4. P. Y. Hou, J Am Ceram Soc 2003, vol. 86, pp. 660-668.

5. M. Shimada, H. Kokawa, Z. J. Wang, Y. S. Sato and I. Karibe, Acta Mater 2002, vol. 50, pp. 2331-2341.

6. R. L. Coble, J Appl Phys 1963, vol. 34, pp. 1679-1682.

7. U. Lienert, S. F. Li, C. M. Hefferan, J. Lind, R. M. Suter, J. V. Bernier, N. R. Barton, M. C. Brandes, M. J. Mills, M. P. Miller, B. Jakobsen and W. Pantleon, Jom-Us 2011, vol. 63, pp. 70-77.

L.E. Shoemaker: Superalloys 718, 625, 706 and Derivatives, Proceedings 2005, pp. 409–18.

9. E. A. Groshart, Met Finish 1984, vol. 82, pp. 49-51.

D. Nguyen, A. W. Thompson and I. M. Bernstein, Acta Metall Mater 1987, vol. 35, pp. 2417-2425.

M. Seita, J. P. Hanson, S. Gradecak and M. J. Demkowicz, Nat Commun 2015, vol. 6, p. 6161

10. C. Goux, Can Metall Quart 1974, vol. 13, pp. 9-31.

A. Morawiec: Grain Growth Polycryst. Mater. III 1998, pp. 509–14.

12. D. M. Saylor, A. Morawiec, B. L. Adams and G. S. Rohrer, Interface Sci 2000, vol. 8, pp. 131-140.

13. V. Randle, Acta Mater 1998, vol. 46, pp. 1459-1480.

14. F. Heidelbach, H. R. Wenk, S. R. Chen, J. Pospiech and S. I. Wright, Mat Sci Eng a-Struct 1996, vol. 215, pp. 39-49.

J. Pospiech, K. Sztwiertnia and F. Haessner, Texture Microstruct 1986, vol. 6, pp. 201-215.

15. D. M. Saylor, A. Morawiec and G. S. Rohrer, Acta Mater 2003, vol. 51, pp. 3663-3674.

J. Alkemper and P. W. Voorhees, Acta Mater 2001, vol. 49, pp. 897-902.

16. W. M. Williams and C. S. Smith, T Am I Min Met Eng 1952, vol. 194, pp. 755-765.

17. J. Li, S. J. Dillon and G. S. Rohrer, Acta Mater 2009, vol. 57, pp. 4304-4311.

18. S. J. Dillon and G. S. Rohrer, J Am Ceram Soc 2009, vol. 92, pp. 1580-1585.

19. H. F. Poulsen, S. F. Nielsen, E. M. Lauridsen, S. Schmidt, R. M. Suter, U. Lienert, L. Margulies, T. Lorentzen and D. J. Jensen, J Appl Crystallogr 2001, vol. 34, pp. 751-756.

20. B. W. Krakauer and D. N. Seidman, Interface Sci 2000, vol. 8, pp. 27-40.

21. J. Duyster and B. Stockhert, Contrib Mineral Petr 2001, vol. 140, pp. 567-576.

22. H. F. Poulsen, Springer Tr Mod Phys 2004, vol. 205, pp. 1-5.

R. M. Suter, D. Hennessy, C. Xiao and U. Lienert, Rev Sci Instrum 2006, vol. 77, p. 123905

23. A. D. Rollett, S. B. Lee, R. Campman and G. S. Rohrer, Annu Rev Mater Res 2007, vol. 37, pp. 627-658.

24. C. M. Hefferan, J. Lind, S. F. Li, U. Lienert, A. D. Rollett and R. M. Suter, Acta Mater 2012, vol. 60, pp. 4311-4318.

25. C. M. Hefferan, S. F. Li, J. Lind and R. M. Suter, Powder Diffr 2010, vol. 25, pp. 132-137.

C. M. Hefferan, S. F. Li, J. Lind, U. Lienert, A. D. Rollett, P. Wynblatt and R. M. Suter, Cmc-Comput Mater Con 2009, vol. 14, pp. 209-219.

S.F. Li: Ph.D. Thesis, Carnegie Mellon University, 2011.

S. F. Li and R. M. Suter, J Appl Crystallogr 2013, vol. 46, pp. 512-524.

26. P. G. Kotula, G. S. Rohrer and M. P. Marsh, Mrs Bull 2014, vol. 39, pp. 361-365.

FEI Visualization Sciences Group: Avizo, 2013. http://www.vsg3d.com/avizo/overview.

M.A. Groeber and M.A. Jackson: Integrating Materials and Manufacturing Innovation 2014, vol. 3.

D. M. Saylor, J. Fridy, B. S. El-Dasher, K. Y. Jung and A. D. Rollett, Metall Mater Trans A 2004, vol. 35A, pp. 1969-1979.

M. Groeber, S. Ghosh, M. D. Uchic and D. M. Dimiduk, Acta Mater 2008, vol. 56, pp. 1257-1273.

M. Groeber, S. Ghosh, M. D. Uchic and D. M. Dimiduk, Acta Mater 2008, vol. 56, pp. 1274-1287.

Kitware: ParaView, 2013. http://www.paraview.org/.

30. D. M. Saylor, B. S. El Dasher, A. D. Rollett and G. S. Rohrer, Acta Mater 2004, vol. 52, pp. 3649-3655.

31. J. P. Hanson, M. Seita, E. Jones, S. Gradecak and M. J. Demkowicz, CORROSION 2015. Dallas, Texas: NACE International 2015.

S. Mannan and F. Veltry: Superalloys 718, 625, 706 and Various Derivatives 2001, pp. 345–56.

33. J. C. Tucker, L. H. Chan, G. S. Rohrer, M. A. Groeber and A. D. Rollett, Scripta Mater 2012, vol. 66, pp. 554-557.

34. K. Okazaki and H. Conrad, Metall Trans 1972, vol. 3, pp. 2411-2421.

F. N. Rhines and B. R. Patterson, Metall Trans A 1982, vol. 13, pp. 985-993.

H. Conrad, M. Swintowski and S. L. Mannan, Metall Trans A 1985, vol. 16, pp. 703-708.

M. F. Vaz and M. A. Fortes, Scripta Metall Mater 1988, vol. 22, pp. 35-40.

A. Cerrone, J. Tucker, C. Stein, A. Rollett, and A. Ingraffea: EMI/PMC 2012, 17–20 June 2012, Notre Dame, IN.

36. D. G. Brandon, Acta Metall Mater 1966, vol. 14, pp. 1479-1484.

A. H. King and S. Shekhar, J Mater Sci 2006, vol. 41, pp. 7675-7682.

37. G. S. Rohrer, D. M. Saylor, B. El Dasher, B. L. Adams, A. D. Rollett and P. Wynblatt, Z Metallkd 2004, vol. 95, pp. 197-214.

38. J. K. Mackenzie, Biometrika 1958, vol. 45, pp. 229-240.

39. V. Randle, G. S. Rohrer, H. M. Miller, M. Coleman and G. T. Owen, Acta Mater 2008, vol. 56, pp. 2363-2373.

40. G. S. Rohrer, V. Randle, C. S. Kim and Y. Hu, Acta Mater 2006, vol. 54, pp. 4489-502.

41. D. L. Olmsted, S. M. Foiles and E. A. Holm, Acta Mater 2009, vol. 57, pp. 3694-703.

G. S. Rohrer, E. A. Holm, A. D. Rollett, S. M. Foiles, J. Li and D. L. Olmsted, Acta Mater 2010, vol. 58, pp. 5063-5069.

42. V. Randle and G. Owen, Acta Mater 2006, vol. 54, pp. 1777-1783.

H. Akhiani, M. Nezakat, M. Sanayei, and J. Szpunar, Mater. Sci. Eng. A, 2015, vol. 626, pp. 51–60.

43. V. Randle, Acta Mater 2004, vol. 52, pp. 4067-4081.

C.F. Hefferan: Carnegie Mellon University 2012.

J.P. Hanson, A. Bagri, J. Lind, P. Kenesei, R.M. Suter, S. Gradecak, and M.J. Demkowicz: in preparation 2016.

Acknowledgments

This work was supported by the BP-MIT Materials and Corrosion Center. This research used resources at the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. AB acknowledges support from the National Science Foundation, Grant No. 1150862, in HEDM data analysis. JPH thanks the Department of Energy Office of Science Graduate Fellowship Program (DOE SCGF), made possible in part by the American Recovery and Reinvestment Act of 2009, administered by ORISE-ORAU under Contract No. DE-AC05-06OR23100. Work at CMU was supported by the Department of Energy/Basic Energy Sciences Grant DESC0002001. Computational support for this research was provided by Grant TG-DMR130061 from the National Science Foundation’s Extreme Science and Engineering Discovery Environment (XSEDE) advanced support program.

Author information

Authors and Affiliations

Corresponding author

Additional information

The submitted manuscript has been created by UChicago Argonne, LLC, Operator of Argonne National Laboratory (“Argonne”). Argonne, a U.S. Department of Energy Office of Science laboratory, is operated under Contract no. DE-AC02-06CH11357. The U.S. Government retains for itself, and others acting on its behalf, a paid-up nonexclusive, irrevocable worldwide license in said article to reproduce, prepare derivative works, distribute copies to the public, and perform publicly and display publicly, by or on behalf of the Government.

Manuscrtipt submitted March 4, 2016.

Rights and permissions

About this article

Cite this article

Bagri, A., Hanson, J.P., Lind, J. et al. Measuring Grain Boundary Character Distributions in Ni-Base Alloy 725 Using High-Energy Diffraction Microscopy. Metall Mater Trans A 48, 354–361 (2017). https://doi.org/10.1007/s11661-016-3831-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3831-x