Abstract

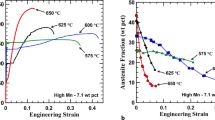

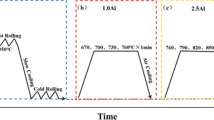

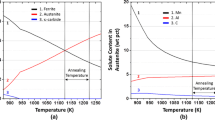

Medium manganese steels alloyed with sufficient aluminum and silicon amounts contain high fractions of retained austenite adjustable to various transformation-induced plasticity/twinning-induced plasticity effects, in addition to a reduced density suitable for lightweight vehicle body-in-white assemblies. Two hot rolled medium manganese steels containing 3 wt pct aluminum and 3 wt pct silicon were subjected to different annealing treatments in the present study. The evolution of the microstructure in terms of austenite transformation upon reheating and the subsequent austenite decomposition during quenching was investigated. Manganese content of the steels prevailed the microstructural response. The microstructure of the leaner alloy with 7 wt pct Mn (7Mn) was substantially influenced by the annealing temperature, including the variation of phase constituents, the morphology and composition of intercritical austenite, the Ms temperature and the retained austenite fraction. In contrast, the richer variant 10 wt pct Mn steel (10Mn) exhibited a substantially stable ferrite-austenite duplex phase microstructure containing a fixed amount of retained austenite which was found to be independent of the variations of intercritical annealing temperature. Austenite formation from hot band ferrite-pearlite/bainite mixtures was very rapid during annealing at 1273 K (1000 °C), regardless of Mn contents. Austenite growth was believed to be controlled at early stages by carbon diffusion following pearlite/bainite dissolution. The redistribution of Mn in ferrite and particularly in austenite at later stages was too subtle to result in a measureable change in austenite fraction. Further, the hot band microstructure of both steels contained a large fraction of coarse-grained δ-ferrite, which remained almost unchanged during intercritical annealing. A recently developed thermodynamic database was evaluated using the experimental data. The new database achieved a better agreement with the experimental results for the 7Mn steel compared with the existing commercial TCFE database; however, some discrepancy in the predicted phase fractions and compositions still existed. The phase transformation behavior of the two steels during annealing and its implication on the design of high aluminum-silicon medium manganese steels were discussed in detail.

Similar content being viewed by others

References

N. Fonstein: Advanced High Strength Sheet Steels: Physical Metallurgy, Design, Processing, and Properties, Springer International Publishing Switzerland 2015, 2015, pp. 297–323

2. Y.K. Lee and J. Han: Mater. Sci. Technol., 2015, vol. 31, pp. 843-56.

3. O. Bouaziz, H. Zurob, and M. Huang: Steel Res. Int., 2013. vol. 84, pp. 937-47.

4. R.L. Miller: Metall. Trans., 1972, vol. 3, pp. 905-12.

5. H. Aydin, E. Essadiqi, I.H. Jung, and S. Yue: Mater. Sci. Eng. A, 2013, vol. 564, pp. 501-08.

6. A. Arlazarov, M. Gouné, O. Bouaziz, A. Hazotte, G. Petitgand, and P. Barges: Mater. Sci. Eng. A, 2012, vol. 542, pp. 31-39.

7. P.J. Gibbs, E. De Moor, M.J. Merwin, B. Clausen, J.G. Speer, and D.K. Matlock: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3691-702.

8. S. Lee and B.C. De Cooman: Metall. Mater. Trans. A, 2013, vol. 44, pp. 5018-24.

9. S.Lee, S.J. Lee, S.S. Kumar, K. Lee, and B.C. De Cooman: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3638-51.

10. W. Cao, C. Wang, J. Shi, M. Wang, W. Hui, and H. Dong: Mater. Sci. Eng. A, 2011, vol. 528, pp. 6661-66.

11. H. Huang, O. Matsumura, and T. Furukawa: Mater. Sci. Technol., 1994, vol. 10, pp. 621-26.

12. E. De Moor, D.K. Matlock, J.G. Speer, and M.J. Merwin: Scripta Mater., 2011, vol. 64, pp. 185-88.

P.J. Gibbs: Design Considerations for the Third Generation Advanced High Strength Steel, Metallurgical and Materials Engineering, Colorado School of Mines, Golden, CO, United States, 2012, pp. 1-79.

14. S. Lee, S.J. Lee, and B.C. De Cooman: Scripta Mater., 2011, vol. 65, pp. 225-28.

15. S. Lee and B.C. De Cooman: Steel Research Int., 2015, vol 86. pp.1-9.

16. S. Lee and B.C. De Cooman: Metall. Mater. Trans. A, 2014, vol. 45, pp. 6039-52.

17. B. Sun, H. Aydin, F. Fazeli, and S. Yue: Metall. Mater. Trans. A, 2016, vol.47, pp. 1782-91.

18. S.S. Sohn, K. Choi, J.H. Kwak, N.J. Kim, and S. Lee: Acta Mater., 2014, vol. 78, pp. 181-89.

19. C.Y. Lee, J. Jeong, J. Han, S.J. Lee, S. Lee, and Y.K. Lee: Acta Mater., 2015, vol. 84, pp. 1-8.

20. S. Lee, K. Lee, and B.C. De Cooman: Metall. Mater. Trans. A, 2015, vol. 46, pp. 2356-63.

21. H. Kim, D.W. Suh, and N.J. Kim: Sci. Technol. Adv. Mater., 2013, vol. 14, pp. 1-11.

22. H. Aydin, I.H. Jung, E. Essadiqi, and S. Yue: Mater. Sci. Eng. A, 2014, vol. 591, pp. 90-96.

23. K. Jeong, J.E. Jin, Y.S. Jung, S. Kang, and Y.K. Lee: Acta Mater., 2013, vol. 61, pp. 3399-410.

24. B.W. Oh, S.J. Cho, Y.G. Kim, Y.P. Kim, W.S. Kim, and S.H. Hong: Mater. Sci. Eng. A, 1995, vol. 197, pp. 147-56.

25. D.W. Suh, S.J. Park, T.H. Lee, C.S. Oh, and S.J. Kim: Metall. Mater. Trans. A, 2010, vol. 41, pp. 397-408.

26. S. Lee, Y. Estrin, and B.C. De Cooman: Metall. Mater. Trans. A, 2013, vol.44, pp. 3136-46.

B. Sun, H. Aydin, F. Fazeli and S. Yue: MS and T 2015 Conf. Proc., Columbus, United States, 2015, pp. 893–900

28. R.A. Young: The Rietveld Method, International Union of Crystallograhy, Oxford, New York, 1995.

ASTM Standard E1245 - 03: Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis, ASTM International, West Conshohocken, PA, 2012. www.astm.org.

ASTM Standard E112 - 12: Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, PA, 2012. www.astm.org.

N.H van Dijk, A.M Butt, L. Zhao, J. Sietsma, S.E Offerman, J.P Wright, and S. Van der Zwaag: Acta Mater., 2005, vol. 53, pp. 5439-47.

32. D.J. Dyson and B. Holmes: J Iron Steel Inst., 1970, vol. 208, pp. 469-74.

BD Cullity: Elements of X-Ray Diffraction, 2nd ed., Addison-Wesley Pub. Co., Cambridge, 1978, pp. 459.

34. M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738-46.

35. S.J. Lee, S. Lee, and B.C. De Cooman: Int. J. Mater. Res., 2013, vol. 104, pp. 423-29.

36. D.P. Koistinen and R.E. Marburger: Acta Metall., 1959, vol. 7, pp. 59-60.

37. S.J. Lee and C.J. Van Tyne: Metall. Mater. Trans. A, 2012, vol. 43, pp. 422-27.

38. S.J. Lee, S. Lee, and B.C. De Cooman: Scripta Mater., 2011, vol. 64, pp. 649-52.

39. M. Cai, Z. Li, Q. Chao, and P.D. Hodgson: Metall. Mater. Trans. A, 2014, vol. 45, pp. 5624-34.

International Molybdenum Association (IMOA): Practical guidelines for the fabrication of duplex stainless steels, 2nd ed., International Molybdenum Association (IMOA), London, UK, 2009, pp. 10–13.

41. S.W. Hwanga, J.H. Jib, E.G. Leeb, and K.T. Park: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5196-203.

42. D.W. Suh, J.H. Ryu, M.S. Joo, H.S. Yang, K. Lee, and H.K.D.H. Bhadeshia: Metall. Mater. Trans. A, 2013, vol. 44, pp. 286-93.

43. T. Furukawa: Mater. Sci. Technol., 1989, vol. 5, pp. 465-70.

44. J. Han and Y.K. Lee: Acta Mater., 2014, vol. 67, pp. 354-61.

B. Hallstedt, A.V. Khvan, B.B. Lindahl, and M. Selleby: CALPHAD XLIV, Loano, Italy, 2015, unpublished research

46. G.R. Speich, V.A. Demarest, and R.L. Miller: Metall. Trans. A, 1981, vol. 12, pp. 1419-28.

47. X.L. Cai, A.J. Garratt-Reed, and W.S. Owen: Metall. Trans. A, 1985, vol. 16, pp. 543-57.

48. J. Ågren: Acta Metall., 1982, vol. 30, pp. 841-51.

49. A. Arlazarov: Evolution of Microstructure and Mechanical Properties of Medium Mn Steels and Their Relationship, University of Lorraine, France, 2015, pp. 109-17.

Q. Lai: Optimization of the Microstructure of Ferritic-Martensitic Steels with 3.5 wt. % Mn: Phase Transformations and Micromechanical Modeling, Joseph Fourier University, France, 2014, pp. 44–64.

51. M. Gouné, P. Maugis, and J. Drillet: J. Mater. Sci. Technol., 2012, vol. 28, pp. 728-36.

52. G.R. Speich, A. Szirmae, and M.J. Richards: Trans. TMS-AIME, 1969, vol. 245, pp. 1063-74.

53. J.R. Yang and H.K.D.H. Bhadeshia: Mater. Sci. Eng. A, 1989, vol. 118, pp 155-70.

54. C. Wells and R.F. Mehl: Trans. Am. Inst. Min. Met. Pet. Eng, 1941, vol. 145, pp. 315-28.

55. J. Ågren: Scripta Metall., 1986, vol. 20, pp. 1507-10.

G. Neumann and C. Tuijn: Self-diffusion and Impurity Diffusion in Pure Metals: Handbook of Experimental Data, 1st ed., Elsevier Ltd., Oxford, 2009, pp. 261-274.

57. J.S. Kirkaldy, P.N. Smith, and R.C. Sharma: Metall. Trans. B, 1973, vol.4, pp. 624-25.

Acknowledgments

The authors gratefully acknowledge Dr. B. Hallstedt from Institute for Materials Applications in Mechanical Engineering (IWM), RWTH Aachen University, for providing the modified thermodynamic database. One of the authors (Binhan Sun) is grateful to the China Scholarship Council (CSC) and the McGill Engineering Doctoral Award (MEDA) program for granting a period of scholarship support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 11, 2016.

Rights and permissions

About this article

Cite this article

Sun, B., Fazeli, F., Scott, C. et al. Phase Transformation Behavior of Medium Manganese Steels with 3 Wt Pct Aluminum and 3 Wt Pct Silicon During Intercritical Annealing. Metall Mater Trans A 47, 4869–4882 (2016). https://doi.org/10.1007/s11661-016-3678-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3678-1