Abstract

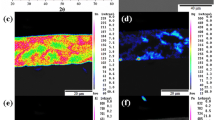

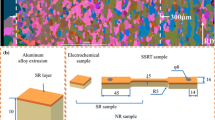

Direct hot press forming of Zn-coated 22MnB5 steels is impeded by micro-cracks that occur in the substrate due to the presence of Zn during the forming process. A study was therefore undertaken to quantify concentration of Zn across the α-Fe(Zn) coating and on grain boundaries in the α-Fe(Zn) layer and the underlying γ-Fe(Zn) substrate after isothermal annealing of Zn-coated 22MnB5 at 1173 K (900 °C) and to link the Zn distribution to the amount and type of micro-cracks observed in deformed samples. Finite difference model was developed to describe Zn diffusion and the growth of the α-Fe(Zn) layer. The penetration of Zn into the γ-Fe(Zn) substrate after 600 seconds annealing at 1173 K (900 °C) through bulk diffusion is estimated to be 3 μm, and the diffusion depth of Zn on the γ-Fe(Zn) grain boundaries is estimated to be 6 μm, which is significantly shorter than the maximum length (15 to 50 μm) of the micro-cracks formed in the severely stressed conditions, indicating that the Zn diffusion into the γ-Fe(Zn) from the α-Fe(Zn) during annealing is not correlated to the depth of micro-cracks. On the other hand, the maximum amount of Zn present in α-Fe(Zn) layer decreases with annealing time as the layer grows and Zn oxidizes, and the amount of Zn-enriched areas inside the α-Fe(Zn) layer is reduced leading to reduced length of cracking. Solid-Metal-Induced Embrittlement mechanism is proposed to explain the benefit of extended annealing on reduced depth of micro-crack penetration into the γ-Fe(Zn) substrate.

Similar content being viewed by others

References

European Automotive Research Partners Association R&D technology Roadmap, http://www.earpa.eu/docs/2005/furore_road_map_final.pdf

T Altan, Update: Hot-stamping boron-alloyed steels for automotive parts, Stamping Journal, March/April, (2011)

S. Kim, I. Son, D. Kim, and S. Kim: 4th Int. Conf. on Hot Sheet Met. Forming of UHSS, Lulea, 2013.

P. Drillet, R. Grigorieva, G. Leuillier, and T. Vietoris: Study of Cracks Propagation Inside the Steel on Press Hardened Steel Zinc Based Coatings, 2011, Galvatech, Genova

M.J. van Genderen, W. Verloop, J. Loiseaux, and G. Hensen: 3rd Int. Conf. on Hot Sheet Met. Forming of UHSS, Kassel, 2011

C.W. Lee, D.W. Fan, I.R. Sohn, S.J. Lee, and B.C. De Cooman: Metall. Mater. Trans. A, 2012, vol. 43, 5122-5127

L Cho, H Kang, C Lee, BC De Cooman, Scripta Mater 90-91 (2014) 25-28.

T. Kurz, G. Luckeneder, T. Manzenreiter, and H. Schwinghammer: Zinc Coated Press-Hardening Steel—Challenges and Solutions, SAE Technical Paper 2015-01-0565, 2015

G. Hensen, W. Melfo, and S.P. Chen: 4th Int. Conf. on Hot Sheet Met. Forming of UHSS, Lulea, 2013.

A.R. Marder: Prog. Mater. Sci., 2000, vol. 45, pp. 199–271.

R Autengruber, G Luckeneder, S Kolnberger, J Faderl, A W Hassel, Steel Research Int 83 (2012) 1005–11

V. Janik, P. Beentjes, D. Norman, G. Hensen, and S. Seetharaman: Proceedings of MST2014 Conference, Pittsburgh, 2014, p. 299

I Richter, M Feller-Kniepmeier, Phys. Status Solidi (A) 68 (1981) 289–300.

E.A. Brandes and G.B. Brook, eds.: Smithells Metals Reference Book, 7th ed., Butterworth & Heinemann, Oxford, 1992.

JS Dohie, JR Cahoon, WF Caley, JPEDAV 28 (2007) 322-327.

P. Heitjans and J. Karger, eds., Diffusion in Condensed Matter: Methods, Materials, Models, 2nd ed., Birkhauser, Boston, 2005.

RTP Whipple, Philos Mag 45 (1954) 1225.

H. Schwinghammer, G. Luckenender, T. Manzenreiter, M. Rosner, P. Tsipouridis, and T. Kurz: 4th Int. Conf. on Hot Sheet Met. Forming of UHSS, Lulea, 2013.

SP Lynch, Mat Sci Eng A108 (1989) 203-212

SP Lynch, Mat Characterization 28 (1992) 279-289.

P. Gordon: Metall. Trans., 1978, vol. 9A, pp. 267–273

S.P. Lynch: Acta Metall., 1988, vol. 36, pp. 2639–61

S.P. Lynch: in Environment Induced Cracking of Materials, S. Shipilov, R. Jones, J.-M. Olive, and R. Rebak, eds., Elsevier, Amsterdam, 2007, pp. 167–177.

S.P. Lynch: Metall. Trans., 2013, vol. 44A, 1209–29.

Acknowledgments

The financial assistance from the WMG Centre High Value Manufacturing Catapult with focus on low C mobility and Tata Steel is gratefully acknowledged. The authors are thankful for the assistance from Dr. Richard Beanland and Steven Hindmarsh at MAS, University of Warwick with the TEM analysis with FIB lift-out. The authors also wish to thank Dr Didier Farrugia for discussing aspects of the diffusion modeling.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 11, 2014.

Rights and permissions

About this article

Cite this article

Janik, V., Lan, Y., Beentjes, P. et al. Zn Diffusion and α-Fe(Zn) Layer Growth During Annealing of Zn-Coated B Steel. Metall Mater Trans A 47, 400–411 (2016). https://doi.org/10.1007/s11661-015-3203-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3203-y