Abstract

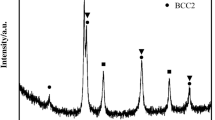

To explore the correlation between the stress corrosion sensitivity and formation processing for high-strength Al-Zn-Mg alloy, extrusion surface and the matrix were investigated by microstructural characterizations, electrochemistry, and stress corrosion cracking (SCC) tests. Larger, but with low density and discontinuity, grain boundary precipitates (GBPs, − 60 nm and − 3.7% area fraction) and intermetallic particles (IMPs, − 0.5% area fraction) were achieved in the secondary recrystallized (SR) coarse-grained layer compared with the non-recrystallized matrix. The maximum Volta potential differences between the IMPs and Al matrix were about 373 mV, causing the pitting initiation by micro-galvanic effect. The decreased pitting density and the low residual stress in the SR layer reduced the available initiation sites for SCC. Thus, the SR layer acted as a barrier layer to reduce the SCC susceptibility of the extruded Al-Zn-Mg alloy in Cl−-containing environments.

taken from the extruded Al-Zn-Mg alloy

Similar content being viewed by others

References

S.P. Knight, K. Pohl, N.J.H. Holroyd, N. Birbilis, P.A. Rometsch, B.C. Muddle, R. Goswami and S.P. Lynch, Some Effects of Alloy Composition on Stress Corrosion Cracking in Al-Zn-Mg-Cu Alloys, Corros. Sci., 2015, 98, p 50–62.

P.K. Rout, M.M. Ghosh and K.S. Ghosh, Effect of Solution pH on Electrochemical and Stress Corrosion Cracking Behaviour of a 7150 Al–Zn–Mg–Cu alloy, Mater. Sci. Eng. A, 2014, 604, p 156–165.

Y. Zhang, S. Jin, P.W. Trimby, X. Liao, M.Y. Murashkin, R.Z. Valiev, J. Liu, J.M. Cairney, S.P. Ringer and G. Sha, Dynamic Precipitation, Segregation and Strengthening of an Al-Zn-Mg-Cu Alloy (AA7075) Processed by High-Pressure Torsion, Acta Mater., 2019, 162, p 19–32.

L. De and W.Z. Pari Jr., Misiolek. Acta. Mater., 2018, 56, p 6174.

T.T. Sasaki, K. Yamamoto, T. Honma, S. Kamado and K. Hono, A High-Strength Mg–Sn–Zn–Al Alloy Extruded at Low Temperature, Scr. Mater., 2008, 59, p 1111–1114.

W.H. Van Geertruyden, H.M. Browne, W.Z. Misiolek and P.T. Wang, Evolution of Surface Recrystallization During Indirect Extrusion of 6xxx Aluminum Alloys, Metall. Mater. Trans. A, 2005, 36(4), p 1049–1056.

P. De Luigi Jr. and Z.M. Wojciech, Theoretical Predictions and Experimental Verification of Surface Grain Structure Evolution for AA6061 During Hot Rolling, Acta Mater., 2008, 56, p 6174–6185.

A. Güzel, A. Jäger, F. Parvizian, H.-G. Lambers, A.E. Tekkaya, B. Svendsen and H.J. Maier, A New Method for Determining Dynamic Grain Structure Evolution During Hot Aluminum Extrusion, J. Mater. Process. Tech., 2012, 212, p 323–330.

Y. Ning and C. Sun, Study on the Coarse and Fine Grains of Aluminum Alloys LY12CZ, Mater. Mech. Eng., 1992, 4, p 39–43.

Z. Peng and T. Sheppard, Simulation of Multi-hole Die Extrusion, Mater. Sci. Eng. A., 2004, 367, p 329–342.

L. Ye, X. Yao, H. Lin, S. Liu, Y. Deng and X. Zhang, Coarse grain layer on stress corrosion cracking resistance of Al–Zn–Mg Alloy, Chinese Materials Conference. Springer, Singapore, 2017, p 337–347

C. Duan, J. Tang, W. Ma, L. Ye, H. Jiang, Y. Deng and X. Zhang, Intergranular Corrosion Behavior of Extruded 6005A Alloy Profile with Different Microstructures, J. Mater. Sci., 2020, 5, p 10833–10848.

X. Zhang, X. Zhou, J.-O. Nilsson, Z. Dong and C. Cai, Corrosion Behaviour of AA6082 Al-Mg-Si Alloy Extrusion: Recrystallized and Non-Recrystallized Structures, Corros. Sci., 2018, 144, p 163–171.

J. Wloka, T. Hack and S. Virtanen, Influence of Temper and Surface Condition on the Exfoliation Behaviour of High Strength Al–Zn–Mg–Cu Alloys, Corros. Sci., 2007, 49, p 1437–1449.

W. Mai and S. Soghrati, A Phase Field Model for Simulating the Stress Corrosion Cracking Initiated from Pits, Corros. Sci., 2017, 125, p 87–98.

L. Chang, M.G. Burke and F. Scenini, Stress Corrosion Crack Initiation in Machined Type 316L Austenitic Stainless Steel in Simulated Pressurized Water Reactor Primary Water, Corros. Sci., 2018, 138, p 54–65.

Li. Wang, C. Dong, J. Yao, Z. Dai, C. Man, Y. Yin and K.X.X. Li, The Effect of ɳ-Ni3Ti Precipitates and Reversed Austenite on the Passive Film Stability of Nickel-Rich Custom 465 Steel, Corros. Sci., 2019, 154, p 178–190.

S.K. Kairy, S. Turk, N. Birbilis and A. Shekhter, The Role of Microstructure and Microchemistry on Intergranular Corrosion of Aluminum Alloy AA7085-T7452, Corros. Sci., 2018, 143, p 414–427.

H.C. Ma, Z.Y. Liu, C.W. Du, H.R. Wang, X.G. Lia, D.W. Zhang and Z.Y. Cui, Stress Corrosion Cracking of E690 Steel as a Welded Joint in a Simulated Marine Atmosphere Containing Sulphur Dioxide, Corros. Sci., 2015, 100, p 627–641.

D. Kong, C. Dong, X. Ni, L. Zhang, H. Luo, R. Li, L. Wang, C. Man and X. Li, Superior Resistance to Hydrogen Damage for Selective Laser Melted 316L Stainless Steel in a Proton Exchange Membrane Fuel Cell Environment, Corros. Sci., 2020, 166, p 108425.

X. Wang, Q. Pan, L. Liu, S. Xiong, W. Wang, J. Lai, Y. Sun and Z. Huang, Characterization of Hot Extrusion and Heat Treatment on Mechanical Properties in a Spray Formed Ultra-High Strength Al-Zn-Mg-Cu Alloy, Mater. Charact., 2018, 144, p 131–140.

G. Sha and A. Cerezo, Early-stage Precipitation in Al–Zn–Mg–Cu Alloy (7050), Acta Mater., 2004, 52(15), p 4503–4516.

R. Goswami, S. Lynch, N.J. Henry Holroyd, S.P. Knight and R.L. Holtz, Evolution of Grain Boundary Precipitates in Al 7075 Upon Aging and Correlation with Stress Corrosion Cracking Behavior, Metall. Mater. Trans. A, 2013, 44, p 1268–1278.

P.K. Poulose, J.E. Morral and A.J. Mcevily, Stress Corrosion Crack Velocity and Grain Boundary Precipitates in an Al-Zn-Mg Alloy, Metall. Mater. Trans. A, 1974, 5(6), p 1393–1400.

A. Wagner and R.N. Shenoy, The Effect of Copper, Chromium, and Zirconium on the Microstructure and Mechanical Properties of Al-Zn-Mg-Cu alloys, Metall. Mater Trans. A., 1991, 22, p 2809–2818. https://doi.org/10.1007/BF02851375

T.M. Yue, L.J. Yan, C.P. Chan, C.F. Dong, H.C. Man and G.K.H. Pang, Excimer Laser Surface Treatment of Aluminum alloy AA7075 to Improve Corrosion Resistance, Surf. Coat. Tech., 2004, 179, p 158–164.

G. Šekularac and I. Milošev, Corrosion of Aluminium Alloy AlSi7Mg03 in Artificial Sea Water with Added Sodium Sulphide, Corros. Sci., 2018, 144, p 54–73.

P. Yi, C. Dong, K. Xiao, C. Man and X. Li, In-situ Investigation of The Semi Conductive Properties and Protective Role of Cu2O Layer Formed on Copper in a Borate Buffer Solution, J. Electroanal. Chem., 2018, 809, p 52–58.

D. Kong, C. Dong, X. Ni, L. Zhang, J. Yao, C. Man, X. Cheng, K. Xiao and X. Li, Mechanical Properties and Corrosion Behavior of Selective Laser Melted 316L Stainless Steel After Different Heat Treatment Processes, J. Mater. Sci. Technol., 2019, 35(7), p 1499–1507.

M. Urquidi and D.D. Macdonald, Solute-Vacancy Interaction Model and the Effect of Minor Alloying Elements on the Initiation of Pitting Corrosion, J. Electrochem. Soc., 1985, 132(3), p 555–558.

F.-l Zeng, Z.-L. Wei, J.-F. Li, C.-X. Li, X. Tan, Z. Zhang and Z.-Q. Zheng, Corrosion Mechanism Associated with Mg2Si and Si Particles in Al–Mg–Si Alloys, Trans. Nonferrous Metals Soc., 2011, 21, p 2559–2567.

E. McCafferty, Sequence of Steps in the Pitting of Aluminum by Chloride Ions, Corros. Sci., 2003, 45(7), p 1421–1438.

N. Birbilis, M.K. Cavanaugh and R.G. Buchheit, Electrochemical Behavior and Localized Corrosion Associated with Al7Cu2Fe Particles in Aluminum alloy 7075–T651, Corros. Sci., 2006, 48(12), p 4202–4215.

Lu. Yalin, J. Wang, X. Li, W. Li, R. Li and D. Zhou, Effects of Pre-Deformation on the Microstructures and Corrosion Behavior of 2219 Aluminum Alloys, Mater. Sci. Eng. A, 2018, 723, p 204–211.

P.S. Pao, S.J. Gill and C.R. Feng, On Fatigue Crack Initiation from Corrosion Pits in 7075–t7351 Aluminum Alloy, Scr. Mater., 2000, 43, p 391–396.

A.C.U. Rao, V. Vasu, M. Govindaraju and K.V.S. Srinadh, Stress Corrosion Cracking Behaviour of 7xxx Aluminum Alloys: A Literature Review, Trans. Nonferrous Metals Soc., 2016, 26(6), p 1447–1471.

G.S. Chen, K.C. Wan, M. Gao, R.P. Wei and T.H. Flournoy, Transition from Pitting to Fatigue Crack Growth-Modeling of Corrosion Fatigue Crack Nucleation in a 2024–T3 Aluminum Alloy, Mater. Sci. Eng. A, 1996, 219(1–2), p 126–132.

H.C. Fang, F.H. Luo and K.H. Chen, Effect of Intermetallic Phases and Recrystallization on the Corrosion and Fracture Behavior of an Al-Zn-Mg-Cu-Zr-Yb-Cr Alloy, Mater. Sci. Eng. A., 2017, 684, p 480–490.

X.M. Li and M.J. Starink, Identification and Analysis of Intermetallic Phases in Overaged Zr-Containing and Cr-Containing Al-Zn-Mg-Cu Alloys, J. Alloy Compd., 2011, 509(2), p 471–476.

M.H. Maghsoudi, A. Zarei-Hanzaki, H.R. Abedi et al., The Evolution of γ-Mg17Al12 Intermetallic Compound During Accumulative Back Extrusion and Subsequent Ageing Treatment, Philos. Mag., 2015, 95(31), p 3497–3523.

K.D. Ralston, N. Birbilis, M. Weyland and C.R. Hutchinson, The Effect of Precipitate Size on the Yield Strength-Pitting Corrosion Correlation in Al–Cu–Mg Alloys, Acta Mater., 2010, 58(18), p 5941–5948.

N. Li, C.F. Dong, C. Man and J.Z. Yao, In situ Electrochemical Atomic Force Microscopy and Auger Electro Spectroscopy Study on The Passive Film Structure of 2024–T3 Aluminum Alloy Combined with a Density Functional Theory Calculation, Adv. Eng. Mater., 2019, 21, p 1900386.

T.J. Stannard, J.J. Williams, S.S. Singh, A.S.S. Singaravelu, X. Xiao and N. Chawla, 3D Time-Resolved Observations of Corrosion and Corrosion-Fatigue Crack Initiation and Growth in Peak-Aged Al 7075 Using Synchrotron X-ray Tomography, Corros. Sci., 2018, 138, p 340–352.

B.J. Wang, D.K. Xub, J. Sun and E.H. Han, Effect of Grain Structure on The Stress Corrosion Cracking (SCC) Behavior of An as-Extruded Mg-Zn-Zr alloy, Corros. Sci., 2019, 157, p 347–356.

Y. Du, Y.A. Chang, B. Huang, W. Gong, Z. Jin, H. Xu, Z. Yuan, Y. Liu, Y. He and F.Y. Xie, Diffusion Coefficients of Some Solutes in fcc and Liquid Al: Critical Evaluation and Correlation, Mater. Sci. Eng. A, 2003, 363, p 140–151.

Y. Wang, L. Cao, X. Wu, X. Tong, B. Liao, G. Huang and Z. Wang, Effect of Retrogression Treatments on Microstructure, Hardness and Corrosion Behaviors of Aluminum Alloy 7085, J. Alloy Compd., 2020, 814, p 152264.

C. Meng, Di. Zhang, L. Zhuang and J. Zhang, Correlations Between Stress Corrosion Cracking, Grain Boundary Precipitates and Zn Content of Al–Mg–Zn Alloys, J. Alloy Compd., 2016, 655, p 178–187.

Y. Ji, C. Dong, L. Chen, K. Xiao and X. Li, High-Throughput Computing for Screening the Potential Alloying Elements of a 7xxx Aluminum Alloy for Increasing the Alloy Resistance to Stress Corrosion Cracking, Corros. Sci., 2021, 183, p 109304.

X. Fang, M. Song, K. Li, Y. Du, D.D. Zhao, C. Jiang and H. Zhang, Effects of Cu and Al on the Crystal Structure and Composition of η (MgZn2) Phase in Over-aged Al–Zn–Mg–Cu Alloys, J. Mater. Sci., 2012, 47, p 5419–5427.

T. Ramgopal, P. Schmutz and G.S. Frankel, Electrochemical Behavior of Thin Film Analogs of Mg(Zn, Cu, Al)2, J. Electrochem. Soc., 2001, 148, p B348–B356.

X.Y. Sun, B. Zhang, H.Q. Lin, Y. Zhou, L. Sun, J.Q. Wang, E.H. Han and W. Ke, Correlations Between Stress Corrosion Cracking Susceptibility and Grain Boundary Microstructures for an Al–Zn–Mg Alloy, Corros. Sci, 2013, 77, p 103–112.

K. Rajan, W. Wallace and J.C. Beddoes, Microstructural Study of a High-Strength Stress-Corrosion Resistant 7075 Aluminum Alloy, J. Mater. Sci., 1982, 17(10), p 2817–2824.

H. Su, H. Toda, R. Masunaga, K. Shimizu, H. Gao, K. Sasaki, M.S. Bhuiyan, K. Uesugi, A. Takeuchi and Y. Watanabe, Influence of Hydrogen on Strain Localization and Fracture Behavior in AlZnMgCu Aluminum Alloys, Acta Mater., 2018, 159, p 332–343.

Y. Li, Z. Liu, E. Fan, Y. Huang, Yi. Fan and B. Zhao, Effect of Cathodic Potential on Stress Corrosion Cracking Behavior of Different Heat-Affected Zone Microstructures of E690 Steel in Artificial Seawater, J. Mater. Sci. Technol., 2021, 64, p 141–152.

D. Kong, X. Ni, C. Dong, X. Lei, L. Zhang, C. Man, J. Yao, X. Cheng and X. Li, Bio-Functional and Anti-Corrosive 3D Printing 316L Stainless Steel Fabricated by Selective Laser Melting, Mater. Design., 2018, 152, p 88–101.

P. Marcus, V. Maurice and H.H. Strehblow, Localized Corrosion (Pitting): A Model of Passivity Breakdown Including the Role of the Oxide Layer Nanostructure, Corros. Sci., 2008, 50, p 2704.

Acknowledgments

This work was supported by the National Key Research and Development Program of China (No. 2017YFB0702300), Fundamental Research Funds for the Central Universities (No. FRF-TP-19-003B2), and the Leading Talent Engineering Project for Taishan Industry.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ao, M., Dong, C., Li, N. et al. Unexpected Stress Corrosion Cracking Improvement Achieved by Recrystallized Layer in Al-Zn-Mg Alloy. J. of Materi Eng and Perform 30, 6258–6268 (2021). https://doi.org/10.1007/s11665-021-05856-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05856-4