Abstract

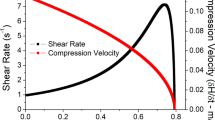

The rheological behavior of an Al-25 mass pct Si alloy, i.e., a hypereutectic Al-Si alloy, was investigated to determine its processability under semi-solid forming conditions. To measure the viscosity of the semi-solid alloy, a parallel-plate drop-forge viscometer similar to that devised by Yurko and Flemings was developed. Drop-forge experiments revealed that the viscosity initially decreased as the shear rate increased and subsequently increased as the shear rate decreased. Thus, the viscosity reached a minimum at approximately the maximum shear rate. The summarized relationship between the viscosity, μ [Pa s], and the shear rate, \( \dot{\gamma } \) [s−1], can be described by the power-law model μ = 1.78 × 107 \( \dot{\gamma } \) −1.5. The decrease in viscosity as a function of the shear rate derived from this equation depends on both the temperature and the applied force but not the duration of deformation. A convex curve was obtained when the effective duration of deformation, i.e., the actual compression time, was plotted as a function of the viscosity and the effective duration of deformation reached a maximum at approximately μ = 30 kPa s (\( \dot{\gamma } \) = 70 s−1). The origin of this profile can be attributed to a combination of both a moderate working time and an adequate deformation, which resulted from a decrease in the deformation resistance accompanied by a lowering of the viscosity. The viscosity at the maximum effective duration of deformation thus corresponds to the transition point for the change in the flow process dominant factor from plastic forming (forging) to casting. Therefore, the viscosity μ = 30 kPa s is believed to be the optimum viscosity for the semi-solid forming of the Al-25 mass pct Si alloy. The approximate temperature condition can be ranged from 855 K to 859 K (582 °C to 586 °C).

Similar content being viewed by others

References

M.C. Flemings, R.G. Rieks, and K.P. Young: Mater. Sci. Eng., 1976, vol. 25, pp. 103-17.

V. Laxmanan and M.C. Flemings: Mettal. Trans. A, 1980, vol. 11A, pp. 1927-37.

P.J. Ward, H.V. Atkinson, P.R.G. Anderson, L.G. Elias, B. Garcia, L. Kahlen, and J-M. Rodrigues-Ibabe: Acta Mater., 1996, vol. 44, pp. 1717-27.

H. Iwasaki, T. Mori, M. Mabuchi, and K. Higashi: Acta Mater., 1998, vol. 46, pp. 6351-60.

J.A. Yurko and M.C. Flemings: Mettal. Mater. Trans. A, 2002, vol. 33A, pp. 2737-46.

K. Solek, Z. Mitura, R. Kuzaik, and P. Kapranos: Solid State Phenom., 2006, vols. 116-117, pp.626-29.

O.Lashkari and R.Ghomashchi: J. Mater. Proc. Technol., 2007, vol. 182, pp. 229-40.

D.H. Kirkwood, M. Suéry, P. Kapranos, H.V. Atkinson, and K.P. Young: Semi-solid Processing of Alloys, Springer Berlin Heidelberg, Germany, 2010.

E.J. Zoqui and M.A. Naldi: J. Mater. Sci., 2011, vol.46, pp. 7558-66.

H.M. Guo, L.J. Wang, Q. Wang, and X.J. Yang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1490-95.

Y. Fukui, H. Okada, N. Kumazawa, and Y. Watanabe: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2627-36.

K. Yamagiwa, Y. Watanabe, K. Matsuda, Y. Fukui, and P. Kapranos: Mater. Sci. Eng. A, 2006, vol. 416, pp. 80-91.

M.C. Flemings: Metall. Trans. A, 1991, vol. 22A, pp. 957-81.

D.H. Kirkwood: Int. Mater. Rev., 1994, vol. 39, pp. 173-89.

T. Chucheep, J. Wannasin, R. Canyook, T. Rattanochaikul, S. Janudom, S. Wisutmethangoon, and M.C. Flemings: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 4754-63.

G.J. Dienes and H.F. Klemm: J. Appl. Phys., 1946, vol. 17, pp. 458-71.

B.K. Prasad, K. Venkateswarlu, O.P. Modi, A.K. Jha, S. Das, R. Dasgupta, and A.H. Yegneswaran: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2747-52.

A. Hekmat-Ardakan and F. Ajersch: Acta Mater., 2010, vol. 58, pp. 3422-28.

M. Sha, S. Wu, X. Wang, L. Wan, and P. An: Mater. Sci. Eng. A, 2012, vol. 535, pp. 258–63.

ASM International Handbook Committee: ASM Handbook, 9th ed., ASM International, Metals Park, OH, 1988, vol. 15, pp. 327–38.

J-J.A. Cheng, D. Apelian, and R.D. Doherty: Metall. Trans. A, 1986, vol. 17A, pp. 2049-62.

Y. Birol: J. Mater Sci., 2008, vol. 43, pp. 3577-81.

D.S.B. Heidary and F. Akhlaghi: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3435-42.

R. Wang and W. Lu: JOM, 2012, vol. 64, No. 2, pp. 330-36.

F.F. Wu, S.T. Li, G.A. Zhang, and F. Jiang: Bull. Mater. Sci., 2014, vol. 37, No. 5, pp. 1153-57.

A.Mazahery and M.O. Shabani: JOM, 2014, vol. 66, No. 5, pp. 726-38.

T.B. Massalski, ed.: Binary Alloy Phase Diagrams, 2nd ed., Plus Updates on CD-ROM Version 1.0, ASM International, 1996.

Acknowledgments

This research work has been partially support by The Light Metal Educational Foundation Incorporated. We would also like to thank Dr Masayuki Toya, a professor emeritus at Kagoshima University, for many discussions during the course of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 13, 2014.

Rights and permissions

About this article

Cite this article

Fukui, Y., Nara, D. & Kumazawa, N. Evaluation of the Deformation Behavior of a Semi-solid Hypereutectic Al-Si Alloy Compressed in a Drop-Forge Viscometer. Metall Mater Trans A 46, 1908–1916 (2015). https://doi.org/10.1007/s11661-015-2777-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2777-8