Abstract

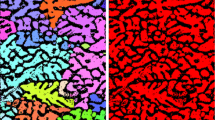

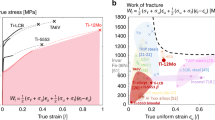

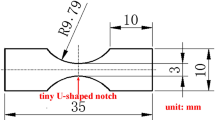

Fracture properties of Ti-based amorphous alloys containing ductile β dendrites were explained by directly observing microfracture processes. Three Ti-based amorphous alloys were fabricated by adding Ti, Zr, V, Ni, Al, and Be into a Ti-6Al-4V alloy by a vacuum arc melting method. The effective sizes of dendrites varied from 63 to 104 μm, while their volume fractions were almost constant within the range from 74 to 76 pct. The observation of the microfracture of the alloy containing coarse dendrites revealed that a microcrack initiated at the amorphous matrix of the notch tip and propagated along the amorphous matrix. In the alloy containing fine dendrites, the crack propagation was frequently blocked by dendrites, and many deformation bands were formed near or in front of the propagating crack, thereby resulting in a zig-zag fracture path. Crack initiation toughness was almost the same at 35 to 36 MPa√m within error ranges in the three alloys because it was heavily affected by the stress applied to the specimen at the time of crack initiation at the crack tip as well as strength levels of the alloys. According to the R-curve behavior, however, the best overall fracture properties in the alloy containing fine dendrites were explained by mechanisms of blocking of the crack growth and crack blunting and deformation band formation at dendrites.

Similar content being viewed by others

References

W. Chen, Y. Wang, J. Qiang, and V. Dong: Acta Mater., 2003, vol. 51, pp. 1899-1907.

H. A. Shivaee, A. Castellero, P. Rizzi, P. Tiberto, H.R.M. Hosseini, and M. Baricco: Met. Mater. Int., 2013, vol. 19, pp. 643-49.

Y.C. Kim, J.M. Park, J.K. Lee, F.H. Bae, W.T. Kim, and D.H. Kim: Mater. Sci. Eng., 2004, vol. A375-377, pp. 749-53.

R. Busch, A. Masuhr, and W.L. Johnson: Mater. Sci. Eng., 2001, vol. A304-306, pp. 97-102.

J.M. Park, H.J. Chang, K.H. Han, W.T. Kim, and D.H. Kim: Scr. Mater., 2005, vol. 53, pp. 1-6.

M. Taboosi, F. Karimzadeh, M.H. Enayati, S. Lee, and H.S. Kim: Met. Mater. Int., 2013, vol. 19, pp. 901-06.

D.E. Polk and D. Turnbull: Acta Metall., 1972, vol. 20, pp. 493-98.

C.A. Pampillow: Scr. Metall., 1972, vol. 6, pp. 915-17.

T.E. Kim, S.W. Sohn, J.M. Park, C.W. Bang, W.T. Kim, and D.H. Kim: Met. Mater. Int., 2013, vol. 19, pp. 667-71.

C.C. Hays, C.P. Kim, and W.L. Johnson: Phys. Rev. Lett., 2000, vol. 84, pp. 2901-04.

C.C. Hays, W.L. Johnson, and C.P. Kim: Mater. Sci. Eng., 2001, vol. A304-306, pp. 650-55.

D.C. Hofmann, J.-Y. Suh, A. Wiest, G. Duan, M.-L. Lind, M.D. Demetriou, and W.L. Johnson: Nature, 2008, vol. 451, pp. 1085-89.

Y.S. Oh, C.P. Kim, S. Lee, and N.J. Kim: Acta Mater., 2011, vol. 59, pp. 7277-86.

D.J. Ha, C.P. Kim, and S. Lee: Mater. Sci. Eng., 2012, vol. A552, pp. 404-09.

D.J. Ha, C.P. Kim, and S. Lee: Mater. Sci. Eng., 2012, vol. A558, pp. 558-65.

D.L. Davison: Metall. Trans., 1987, vol. 18A, pp. 2115-28.

J.G. Lee, D.-G. Lee, S. Lee, and N.J. Kim: Metall. Mater. Trans., 2004, vol. 35A, pp. 3753-61.

S.R. Nutt and L.M. Duva: Scr. Metall., 1986, vol. 20, pp. 1055-58.

M. Tavoosi, M.H. Enayati, and F. Karimzadeh: Met. Mater. Inter., 2011, vol. 17, pp. 853-56.

D.C. Hofmann, J.-Y. Suh, A. Wiest, M.L. Lind, M.D. Demetriou, and W.L. Johnson: Proc. Natl. Acad. Sci. USA, 2008, vol. 105, pp. 20136-40.

C. Jeon, C.P. Kim, S.-H. Joo, H.S. Kim, and S. Lee: Acta Mater., 2013, vol. 61, pp. 3012-26.

M.W. Lee, H.J. Shin, S.H. Hong, J.T. Kim, H. Choi-Yim, Y. Seo, W.H. Lee, P. Yu, M. Qian, J.K. Lee, and K.B. Kim: Met. Mater. Int., 2014, vol 20, pp. 1-5.

J.G. Lee, K.-S. Sohn, S. Lee, N.J. Kim, and C.P. Kim: Mater. Sci. Eng., 2007, vol. A464, pp. 261-68.

C.-Y. Son, C.K. Kim, S.Y. Shin, and S. Lee: Mater. Sci. Eng., 2009, vol. A508, pp. 15-22.

C. Jeon, C.P. Kim, and S. Lee: Metall. Mater. Trans., 2012, vol. 43A, pp. 3675-86.

J.G. Lee, S.S. Park, D.-G. Lee, S. Lee, and N.J. Kim: Intermetallics, 2004, vol. 12, pp. 1125-31.

B. Kim, J. Do, S. Lee, and I. Park: Mater. Sci. Eng., 2010, vol. A527, pp. 6745-57.

D.-G. Lee, S. Lee, and C.S. Lee: Mater. Sci. Eng., 2004, vol. A366, pp. 25-37.

J.W. Qiao, J.T. Zhang, F. Jiang, Y. Zhang, P.K. Liaw, Y. Ren, and G.L. Chen: Mater. Sci. Eng., 2010, vol. A527, pp. 7752-56.

S. Lee, K.-S. Sohn, C.G. Lee, and B.I. Jung: Metall. Mater. Trans., 1997, vol. 28A, pp. 123-34.

J.J. Lewandowski, M. Shazly, and A. Shmimi Nouri: Scr. Mater., 2006, vol. 54, pp. 337-41.

B. Gludovatz, S.E. Naleway, R.O. Ritchie, and J.J. Kruzic: Acta Mater., 2014, vol. 70, pp. 198-207.

D. Broek: Elementary Engineering Fracture Mechanics, Martinus Nijhoff Publishers, Boston, 1982, pp. 297-309.

Acknowledgments

This study was supported by the National Research Foundation of Korea (NRF) Grant (No. 2010-0026981) funded by the Ministry of Education, Science, and Technology, Korea, and by the Brain Korea 21 PLUS Project for Center for Creative Industrial Materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 15, 2014.

Rights and permissions

About this article

Cite this article

Jeon, C., Kim, C.P., Kim, H.S. et al. Interpretation of Fracture Toughness and R-Curve Behavior by Direct Observation of Microfracture Process in Ti-Based Dendrite-Containing Amorphous Alloys. Metall Mater Trans A 46, 1588–1596 (2015). https://doi.org/10.1007/s11661-015-2743-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2743-5