Abstract

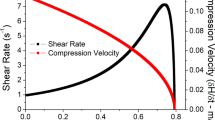

This paper reports the experimental and finite element analyses of the solidification behavior of Al/SiCp composites, fabricated by the squeeze casting technique. Experiments were carried out by varying the melt temperatures for cylindrical-shaped composite castings. The composite samples were produced at the following constant temperatures: melt—1023 K, 1073 K, 1123 K, and 1173 K (750 °C, 800 °C, 850 °C, and 900 °C); and die—673 K (400 °C). The pressure applied throughout the experiment is 100 MPa. The melt temperature shows significant influence on the solidification behavior of the metal matrix composite. It was observed that the solidification time was 40 seconds when the melt temperature was 1023 K (750 °C) but it increased to 51 seconds when the melt temperature was at 1173 K (900 °C). The results also showed that the cooling rate decreased on increasing the melt temperature. Cooling curves for our system, squeeze cast composites, were predicted using the finite element software ANSYS. K-type thermocouples were interfaced to the die and the microcomputer from which the experimental cooling curves were constructed. The experimental and predicted cooling curves were then compared. While both show similar trends, the finite element analysis consistently under-predicts the temperature. In addition, finite element stress analysis reveals that both radial and tangential thermal stresses increase with the melt temperature.

Similar content being viewed by others

References

S. Balasivanandha Prabu, L. Karunamoorthy and S. Kathiresan: J. Mater. Process. Technol, 2006, vol. 171, pp. 268-73.

[2] M. Khakbiz and F. Akhlaghi: J. Alloys. Compd, 2009, vol. 479, p. 334-41.

[3] J. Hashim, L. Looney and M.S.J. Hashmi: J. Mater. Process. Technol, 2002, vol.123, pp. 258-63.

[4] S. Rajagopal: J. Applied Metalworking, 1981, vol.1, pp. 4-14.

[5] M.R. Ghomashchi and A. Vikhrov: J. Mater. Process. Technol, 2000, vol. 101, pp. 1-9.

[6] D.J. Lloyd: Compos. Sci. Technol, 1989, vol. 35, pp.159-79.

[7] G.S. Hanumanth and G.A. Irons: Metall. Mater. Trans B, 1996, vol. 27, pp. 663-71.

[8] T.P.D. Rajan, K. Narayan Prabhu, B.C. Pillai and B.C. Pai: Compos. Sci. Technol, 2007, vol. 67, pp. 70-8.

[9] L.J. Yang: J. Mater. Process. Technol, 2007, vol. 192–193, pp. 114-20.

[10] C.S. Ramesh, S.K. Jagadeesh and R. Keshavamurthy: J. Alloys. Compd, 2011, vol.509S, pp. S371-4.

[11] K.C.Mills: Recommended Values of Thermophysical Properties for Selected Commercial Alloys, first ed., Woodhead Publication Limited, Cambridge, England, 2002, pp. 43-9.

[12] Y.M. Youssef, R.J. Dashwood and P.D. Lee: Composites Part A, 2005, vol. 36 (6), pp.747-63.

[13] S.K. Jagadeesh, C.S. Ramesh, J.M. Mallikarjuna and R. Keshavamurthy: J. Mater. Process. Technol, 2010, vol. 210, pp. 618-23.

[14] M.S. Yong and A.J. Clegg: J. Mater. Process. Technol, 2004, vol. 145, pp. 134-41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 19, 2014.

Rights and permissions

About this article

Cite this article

Gurusamy, P., Balasivanandha Prabu, S. & Paskaramoorthy, R. Prediction of Cooling Curves for Squeeze Cast Al/SiCp Composites Using Finite Element Analysis. Metall Mater Trans A 46, 1697–1703 (2015). https://doi.org/10.1007/s11661-015-2742-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2742-6