Abstract

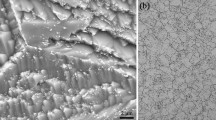

Heat-resistant ferritic steels containing Laves phase precipitates were designed supported by thermodynamic modeling. High-temperature compression tests at 1173.15 K (900 °C) and a detailed characterization of the microstructural evolution during annealing at 1173.15 K (900 °C) were carried out to investigate the effect of Laves phase formation on the high-temperature strength. Due to the addition of W/Mo and/or Nb, the high-temperature strength of the newly designed alloys is significantly higher than that of the reference steels. However, the high-temperature strength of all investigated steels decreases slightly as the annealing time is increased up to 1440 hours. To determine the influence of Laves phase formation and coarsening on the high-temperature strength during long-term annealing, the precipitates were extracted from the ferritic matrix in different annealing states. The phases in the powder residue were determined by XRD, and the chemical composition of the Laves phase in dependence of the annealing time was analyzed by EDS measurements. During annealing, steel Fe18CrMoW forms Nb(C,N), Ti(C,N), Laves phase (Fe2Nb) and Fe3Nb3C, whereas alloy Fe19CrWAl forms Nb(C,N), Ti(C,N), and Laves phase (Fe2Nb). The Laves phase within the alloys Fe18CrMoW and Fe19CrWAl differs in its morphology as well as its chemical composition. The Laves phase in steel Fe18CrMoW attains its chemical equilibrium after 192 hours, whereas alloy Fe19CrWAl required 24 hours. Overall, the formation of the Laves phase prevents significant grain growth during high-temperature annealing, thus preserving the high-temperature strength over a long time period.

Similar content being viewed by others

References

N. Fujita, K. Ohmura, M. Kikuchi, T. Suzuki, S. Funaki and I. Hiroshige: Scripta Materialia, 1996, vol. 35, no. 6 pp. 705–10.

W. Quadakkers, J. Piron-Abellan, V. Shemet and L. Singheiser: Materials at High Temperatures, 2003, vol. 20, no. 2 pp. 115–27.

T. J. Nichol, A. Datta and G. Aggen: Metallurgical Transactions A, 1980, vol. 11, no. 4 pp. 573–85.

A. van Zwieten and J. Bulloch: International Journal of Pressure Vessels and Piping, 1993, vol. 56, no. 1 pp. 1–31.

H. Berns and W. Theisen: Ferrous materials: Steel and cast iron. Springer, Berlin and London, 2008.

Y. Inoue and M. Kikuchi: Nippon Steel Technical Report, 2003, pp. 62–69.

F. Chassagne, J. Mithieux and J. Schmitt: Steel Research International, 2006, vol. 77, no. 9-10 pp. 680–85.

P. O. Santacreu, O. Cleizergues, C. Simon and P. Duroux: Revue De Metallurgie-Cahiers D Informations Techniques, 2004, vol. 101, no. 7-8 pp. 615–20.

F. Abe: Metallurgical and Materials Transactions A, 2005, vol. 36A, pp. 321–32.

Q. Li: Metallurgical and Materials Transactions A, 2006, vol. 37A, pp. 89–97.

A. Miyazaki, K. Takao and O. Furukimi: ISIJ International, 2002, vol. 42, no. 8 pp. 916–20.

G. M. Sim, J. C. Ahn, S. C. Hong, K. J. Lee and K. S. Lee: Materials Science and Engineering: A, 2005, vol. 396, no. 1-2 pp. 159–65.

H. L. Lukas, S. G. Fries and B. Sundman: Computational thermodynamics: The CALPHAD method. Cambridge University Press, Cambridge, 2007.

Thermo-Calc Software: Thermo-Calc—User’s Guide—Version S. Stockholm and Schweden, 2008.

T. Sawatani, S. Minamino and H. Morikawa: Transaction of Iron and Steel Institute of Japan, 1982, vol. 22, no. 3 pp. 172–80.

H. Kutsumi, A. Chino and Y. Ishibashi: Tetsu to Hagane-Journal of the Iron and Steel Institute of Japan, 1992, vol. 78, no. 4 pp. 594–600.

J. Froitzheim, G. Meier, L. Niewolak, P. Ennis, H. Hattendorf, L. Singheiser and W. Quadakkers: Journal of Power Sources, 2008, vol. 178, no. 1 pp. 163–73.

M. Sello and W. Stumpf: Materials Science and Engineering: A, 2010, vol. 527, no. 20 pp. 5194–202.

V. Knežević, J. Balun, G. Sauthoff, G. Inden and A. Schneider: Materials Science and Engineering: A, 2008, vol. 477, no. 1-2 pp. 334–43.

N. Nabiran, S. Weber and W. Theisen: Steel Research International, 2012, vol. 83, no. 8 pp. 758–65.

W. Gordon and A. van Bennekom: Mater. Sci. Technol., 1996, vol. 12 (2) pp. 126–31.

D. Rojas, J. Garcia, O. Prat, C. Carrasco, G. Sauthoff and A. Kaysser-Pyzalla: Materials Science and Engineering: A, 2010, vol. 527, no. 16-17 pp. 3864–76.

Y. Kato, A. Miyazaki and T. Ujiro: JFE Steel, JP, vol. 2008, no. 20 pp. 28–32.

B. Kuhn, C. A. Jimenez, L. Niewolak, T. Hüttel, T. Beck, H. Hattendorf, L. Singheiser and W. Quadakkers: Materials Science and Engineering: A, 2011, vol. 528, no. 18 pp. 5888–99.

Y. Chiu and C. Lin: Journal of Power Sources, 2012, vol. 198 pp. 149–57.

P. W. Voorhees: Journal of Statistical Physics, 1985, vol. 38, no. 1-2 pp. 231–52.

N. Fujita, K. Ohmura and A. Yamamoto: Materials Science and Engineering: A, 2003, vol. 351, no. 1-2 pp. 272–81.

G. Gottstein: Physical foundations of material science. Springer, Berlin, 2004.

Acknowledgments

The authors gratefully acknowledge financial support by the Bundesministerium für Bildung und Forschung (BMBF) for the project “Entwicklung von Höchstleistungswerkstoffen für Hochtemperatur-Wärmetauscher und PKW-Abgasanlagen” (“Development of high-performance materials for high-temperature heat carriers and automotive exhaust systems”) under Contract number 03X3520G.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 9, 2013.

Rights and permissions

About this article

Cite this article

Nabiran, N., Klein, S., Weber, S. et al. Evolution of the Laves Phase in Ferritic Heat-Resistant Steels During Long-term Annealing and its Influence on the High-Temperature Strength. Metall Mater Trans A 46, 102–114 (2015). https://doi.org/10.1007/s11661-014-2505-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2505-9