Abstract

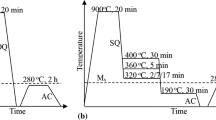

Steels with compositions that are hot rolled and cooled to exhibit high strength and good toughness often require a bainitic microstructure. This is especially true for plate steels for linepipe applications where strengths in excess of 690 MPa (100 ksi) are needed in thicknesses between approximately 6 and 30 mm. To ensure adequate strength and toughness, the steels should have adequate hardenability (C. E. >0.50 and Pcm >0.20), and are thermomechanically controlled processed, i.e., controlled rolled, followed by interrupted direct quenching to below the Bs temperature of the pancaked austenite. Bainite formed in this way can be defined as a polyphase mixture comprised a matrix phase of bainitic ferrite plus a higher carbon second phase or micro-constituent which can be martensite, retained austenite, or cementite, depending on circumstances. This second feature is predominately martensite in IDQ steels. Unlike pearlite, where the ferrite and cementite form cooperatively at the same moving interface, the bainitic ferrite and MA form in sequence with falling temperature below the Bs temperature or with increasing isothermal holding time. Several studies have found that the mechanical properties may vary strongly for different types of bainite, i.e., different forms of bainitic ferrite and/or MA. Thermomechanical controlled processing (TMCP) has been shown to be an important way to control the microstructure and mechanical properties in low carbon, high strength steel. This is especially true in the case of bainite formation, where the complexity of the austenite-bainite transformation makes its control through disciplined processing especially important. In this study, a low carbon, high manganese steel containing niobium was investigated to better understand the effects of austenite conditioning and cooling rates on the bainitic phase transformation, i.e., the formation of bainitic ferrite plus MA. Specimens were compared after transformation from recrystallized, equiaxed austenite to deformed, pancaked austenite, which were followed by seven different cooling rates ranging between 0.5 K/s (0.5 °C/s) and 40 K/s (40 °C/s). The CCT curves showed that the transformation behaviors and temperatures varied with starting austenite microstructure and cooling rate, resulting in different final microstructures. The EBSD results and the thermodynamics and kinetics analyses show that in low carbon bainite, the nucleation rate is the key factor that affects the bainitic ferrite morphology, size, and orientation. However, the growth of bainite is also quite important since the bainitic ferrite laths apparently can coalesce or coarsen into larger units with slower cooling rates or longer isothermal holding time, causing a deterioration in toughness. This paper reviews the formation of bainite in this steel and describes and rationalizes the final microstructures observed, both in terms of not only formation but also for the expected influence on mechanical properties.

Similar content being viewed by others

References

C Isaac Garcia, MJ Hua, X Liang, P Suikannen and Anthony J DeArdo, In Materials Science Forum, (Trans Tech: 2012), Stafa-Zurich pp 17-23.

A.J. DeArdo: Proc. Int. Conference Microalloying. 1995. pp 15–33.

F.G. Caballero and J. Santofimia: Novel High Strength, High Toughness Carbide-Free Bainitic Steels: Final Report, Office for Official Publications of the European Communities, 2007.

X. Liang: Ph.D. Thesis, Mechanical Engineering and Materials Science, University of Pittsburgh, 2012.

Kangying Zhu, Olivier Bouaziz, Carla Oberbillig and Mingxin Huang, Materials Science and Engineering: A 2010, vol. 527, pp. 6614-19.

C. Y. Huang, J. R. Yang and S. C. Wang, Mater Trans Jim 1993, vol. 34, pp. 658-668.

Y. Ohmori, T Iron Steel I Jpn 1973, vol. 13, pp. 56-62.

George Krauss: Steels: processing, structure, and performance. ASM International, Materials Park, OH, 2005.

Stanislaw Zajac, Volker Schwinn and KH Tacke, In Materials Science Forum, (Trans Tech Stafa-Zurich. 2005, pp 387-94.

B.L. Bramfitt and J.G. Speer: Metall. Trans. A, 1990, vol. 21A, pp. 817–29.

H.I. Aaronson, W.T. Reynolds, G.J. Shiflet, and G. Spanos: Metall. Trans. A, 1990, vol. 21A, pp. 1343–80.

P. P. Suikkanen, C. Cayron, A. J. DeArdo and L. P. Karjalainen, J Mater Sci Technol 2013, vol. 29, pp. 359-366.

P. Cizek, B. P. Wynne, C. H. J. Davies, B. C. Muddle and P. D. Hodgson, Metall Mater Trans A 2002, vol. 33, pp. 1331-1349.

H. K. D. H. Bhadeshia, Materials Science and Engineering: A 1999, vol. 273–275, pp. 58-66.

GI Rees and HKDH Bhadeshia, Mater Sci Tech-Lond 1992, vol. 8, pp. 985-993.

GI Rees and HKDH Bhadeshia, Mater Sci Tech-Lond 1992, vol. 8, pp. 994-1003.

S. M. C. van Bohemen, Philos Mag 2013, vol. 93, pp. 388-408.

HKDH Bhadeshia, Acta Metall Mater 1981, vol. 29, pp. 1117-1130.

H.K.D.H. Bhadeshia and J.W. Christian: Metall. Trans. A, 1990, vol. 21A, pp. 767–97.

JC Bokros and ER Parker, Acta Metall Mater 1963, vol. 11, pp. 1291-1301.

J.P. Naylor: Metall. Trans. A, 1979, vol. 10A, pp. 861–73.

XJ Liang, MJ Hua, C Isaac Garcia and Anthony J DeArdo, In Materials Science Forum, Trans Tech, Stafa-Zurich, 2013, pp 38-46.

G. T. Park, S. U. Koh, H. G. Jung and K. Y. Kim, Corros Sci 2008, vol. 50, pp. 1865-1871.

SU Koh, HG Jung, KB Kang, GT Park and KY Kim, Corrosion 2008, vol. 64, pp. 574-585.

E. J. Palmiere, C. I. Garcia and A. J. DeArdo, Metall Mater Trans A 1996, vol. 27, pp. 951-960.

F.G. Caballero, M.K. Miller, S.S. Babu and C Garcia-Mateo, Acta Materialia 2007, vol. 55, pp. 381-390.

H. Bhadeshia and R. Honeycombe: Steels: Microstructure and Properties: Microstructure and Properties. Butterworth-Heinemann, Oxford 2011.

J.W. Christian: The theory of transformations in metals and alloys (part I+ II). Elsevier, Oxford, 2002).

AT Davenport, RE Miner and RA Kot, AIME, New York, NY 1977, vol. 186.

K. Tsuzaki, T. Ueda, K. Fujiwara and T. Maki: Proc. 1st Jpn. Int. SAMPE Symposium and Exhibition, Society for the Advancement of Materials and Process Eng., Chiba, Japan. 1989. pp 699–704.

H.K.D.H. Bhadeshia: University of Cambridge. IOM communications. 2001.

D.A. Porter and K.E. Easterling: Phase transformations in metals and alloys. CRC press, Boca Raton, FL, 1992.

Acknowledgments

The authors would like to thank the United Metallurgical Company (OMK), Vyksa, Russia, for its partial financial support of this work, and the United States Steel Research and Technology Center and the Baosteel Research Institute, especially Dr. Sihai Jiao, for in-kind support. In addition, the authors would like to thank BAMPRI and the Materials Characterization Lab in the MEMS Department at the University of Pittsburgh for providing the facilities used to conduct this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 16, 2014.

Rights and permissions

About this article

Cite this article

Liang, X., DeArdo, A.J. A Study of the Influence of Thermomechanical Controlled Processing on the Microstructure of Bainite in High Strength Plate Steel. Metall Mater Trans A 45, 5173–5184 (2014). https://doi.org/10.1007/s11661-014-2444-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2444-5