Abstract

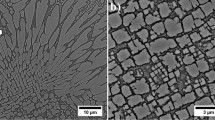

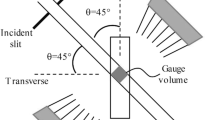

The evolution of lattice misfit in the polycrystalline nickel-base superalloy, RR1000, has been investigated using high resolution neutron diffraction at interrupted time intervals during an aging heat treatment. Samples were subjected to a super-solvus heat treatment followed by either a 100 or a 1 K min−1 cooling rate prior to aging. Irrespective of cooling rate, the lattice misfit remained unchanged at approximately 0.1 pct throughout the aging cycle, indicating the microstructure remained stable. Microstructural observations validated this result for samples cooled at 1 K min−1. However, for the faster, 100 K min−1, cooling rate, whilst the secondary γ′ remained unchanged, the tertiary γ′ showed significant coarsening. Simulated diffraction patterns were used to investigate the influence of volume fraction, particle size, and lattice parameter of individual γ′ distributions on the measured lattice misfit. The results obtained indicate that conventional methods of measuring lattice misfit will be dominated by the γ′ distribution with the highest volume fraction, and may therefore obscure subtle changes in the γ′ distributions with lower a volume fraction.

Similar content being viewed by others

References

R.C. Reed, The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, 2006.

R.J. Mitchell, J.A. Lemsky, R. Ramanathan, H.Y. Li, K.M. Perkins, L.D. Connor, TMS Superalloys, Seven Springs, Pennsylvania, 2008.

L. Connor: Ph.D. Thesis, Department of Materials Science and Metallurgy, University of Cambridge, 2009

S.K. Sondhi, B.F. Dyson, M. McLean, Acta Materialia, 52 (2004) 1761-1772.

M.P. Jackson, R.C. Reed, Materials Science and Engineering A, 259 (1999) 85-97.

J.J. Schirra, P.L. Reynolds: Superalloys, TMS, Warrendale, PA, 2004, pp. 341–50.

J. Lemsky: Assessment of NASA Dual Microstructure Heat Treatment Method Utilizing Ladish SupercoolerTM Cooling Technology, National Aeronautics and Space Administration (NASA), Washington, DC, 2005, p. 15. http://ntrs.nasa.gov/search.jsp.

D.U. Furrer and H.-J. Fecht: Superalloys, TMS, Warrendale, PA, 2000, pp. 415–24.

D.M. Collins, B.D. Conduit, H.J. Stone, M.C. Hardy, G.J. Conduit, R.J. Mitchell, Acta Materialia, 61 (2013) 3378-3391.

J.W. Christian, The Theory of Transformations in Metals and Alloys, Pergamon, Oxford, 2002.

P.W. Voorhees, Journal of Statistical Physics, 38 (1985) 231-252.

L. Ratke, C. Beckermann, Acta Materialia, 49 (2001) 4041-4054.

A.J. Ardell, Metallurgical Transactions A, 16A (1985) 2131-2165.

J. Tiley, G.B. Viswanathan, J.Y. Hwang, A. Shiveley, R. Banerjee, Materials Science and Engineering: A, 528 (2010) 32-36.

J. Li, R.P. Wahi, Acta Metallurgica et Materialia, 43 (1995) 507-517.

R.J. Mitchell, M. Preuss, Metallurgical and Materials Transactions A, 38A (2007) 615-627.

R.J. Mitchell, M. Preuss, M.C. Hardy, S. Tin, Materials Science and Engineering A, 423 (2006) 282-291.

D.M. Collins, L. Yan, E.A. Marquis, L.D. Connor, J.J. Ciardiello, A.D. Evans, H.J. Stone, Acta Materialia, 61 (2013) 7791-7804.

R.M. Ibberson, W.I.F. David, and K.S. Knight: ISIS Spallation Neutron & Muon Source, 1992, p. 24. http://www.isis.stfc.ac.uk/instruments/hrpd/documents/hrpd-documents4439.html.

A.C. Larson and R.B. Von Dreele: General Structure Analysis System (GSAS), Los Alamos National Laboratory Report LAUR 86-748 (1994).

S. Ikeda, J.M. Carpenter, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 239 (1985) 536-544.

Sundman B.: ThermoCalc User Guide, KTH Stockholm, 1993.

ThermoTech Ltd.: TTNi6, TT Ni-based Superalloys Database, Surrey Technology Center, Guildford, 2003.

H.J. Stone, T.M. Holden, R.C. Reed, Acta Materialia, 47 (1999) 4435-4448.

S.J. Hessel, W. Voice, A.W. James, S.A. Blackham, C.J. Small, and M.R. Winstone: Patent Number EP0803585, 2000.

CrystalMaker, Oxfordshire. www.crystalmaker.com. Accessed 8 Dec 2012.

CrystalDiffract, Oxfordshire. www.crystalmaker.com/crystaldiffract/index.html. Accessed 8 Dec 2012.

R.A. Ricks, A.J. Porter, R.C. Ecob, Acta Metallurgica, 31 (1983) 43-53.

A. Hazotte, A. Racine, A. Denis, Journal de Physique IV, 6 (1996) 9.

R.W. Kozar, A. Suzuki, W.W. Milligan, J.J. Schirra, M.F. Savage, T.M. Pollock, Metallurgical and Material Transactions A, 40 (2009) 1588-1603.

D.M. Collins and H.J. Stone: Int. J. Plast., 2014, vol. 54, pp. 96–112.

Acknowledgments

Financial support from the EPSRC and Rolls-Royce plc. is acknowledged (DMC supported by a DTA studentship, HJS supported by the Rolls-Royce EPSRC Strategic Partnership—EP/H500375/1). The authors are grateful to M.C. Hardy and R.J. Mitchell (Rolls-Royce plc.) for their technical support during this work. The authors are additionally grateful for the allocation of experimental time on the HRPD instrument at the ISIS neutron spallation source (RB610489) and the technical support by R.M. Ibberson.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 17, 2013.

Rights and permissions

About this article

Cite this article

Connor, L.D., Stone, H.J., Collins, D.M. et al. The Effect of Cooling Rate from Solution on the Lattice Misfit During Isothermal Aging of a Ni-Base Superalloy. Metall Mater Trans A 45, 2436–2444 (2014). https://doi.org/10.1007/s11661-014-2197-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2197-1