Abstract

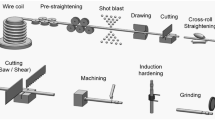

In this investigation, a design of experiments analysis of distortion for a typical manufacturing process involving pre-straightening, cold drawing, and induction hardening of AISI 1045 cylindrical steel bars was carried out. A careful characterization of the material, including residual stress states and geometrical changes, was done for the different manufacturing steps. In order to identify effects and correlations on distortion behavior, the investigated variables included the batch influence, the combined drawing process itself with two different drawing angles and two different polishing and straightening (P.S.) angles, a stress relief treatment which was applied to a part of the samples, and finally induction hardening with two different surface hardening depths. Main and statistically significant effects on the distortion of the induction-hardened samples were found to be in this order: first, the interaction between the drawing angle and batch, then the interaction between drawing angles, and finally drawing angle and induction hardened layer. It was also found that the distortion potentials are transmitted from the drawing process to further manufacturing steps and, consequently, from one production site to the next.

Similar content being viewed by others

Abbreviations

- AISI:

-

American Iron and Steel Institute

- d 0 :

-

Interplanar spacing

- DoE:

-

Design of experiments

- IH:

-

Induction hardening

- PAG:

-

Polyalkylene glycol

- P.S.:

-

Polishing and straightening process

- r :

-

Radius

- RS:

-

Residual stress

- SR:

-

Stress relief

- XRD:

-

X-ray diffraction

- SHD:

-

Surface hardening depth

- α :

-

Statistical significance

- α 1 :

-

Semi-die angle in wire drawing process

References

F. Hoffmann, O. Kessler, T. Lubben and P. Mayr, Heat Treat Met-Uk 2004, vol. 31, pp. 27-30.

H. W. Zoch, Materialwiss Werkst 2012, vol. 43, pp. 9-15.

K. D. Thoben, D. Klein, M. Seifert and T. Wuest, Materialwiss Werkst 2012, vol. 43, pp. 178-185.

H. L. Yu, J. W. Kang and T. Y. Huang, Sci China Technol Sc 2011, vol. 54, pp. 81-87.

H. W. Zoch, Materialwiss Werkst 2006, vol. 37, pp. 6-10.

T. Kuboki, H. Yoshikawa, Y. Neishi, K. Kuroda and M. Akiyama, Ironmak Steelmak 2001, vol. 28, pp. 117-121.

A. S. Rocha, R. M. Nunes and T. Hirsch, P I Mech Eng B-J Eng 2012, vol. 226, pp. 459-465.

H. Surm, O. Kessler, F. Hoffmann and P. Mayr, Int J Mater Prod Tec 2005, vol. 24, pp. 270-281.

F. Frerichs, D. Landek, T. Lubben, F. Hoffmann and H. W. Zoch, Materialwiss Werkst 2006, vol. 37, pp. 63-68.

J. Epp, T. Hirsch, M. Hunkel and R. Wimpory, Mechanical Stress Evaluation by Neutrons and Synchrotron Radiation 2010, vol. 652, pp. 37-43.

J. M. Atienza and M. Elices, Mater Struct 2004, vol. 37, pp. 301-304.

J. M. Atienza and M. Elices, Mater Struct 2003, vol. 36, pp. 548-552.

M. L. Martinez-Perez, F. J. Mompean, J. Ruiz-Hervias, C. R. Borlado, J. M. Atienza, M. Garcia-Hernandez, M. Elices, J. Gil-Sevillano, R. L. Peng and T. Buslaps, Acta Mater 2004, vol. 52, pp. 5303-5313.

K. Tanaka and Y. Akiniwa, Jsme Int J a-Solid M 2004, vol. 47, pp. 252-263.

T. Poeste, R.C. Wimpory, and R. Schneider: Mater. Sci. Forum, 2006, vol. 524–525, pp. 223–28.

M. R. Ripoll, S. M. Weygand and H. Riedel, Mat Sci Eng a-Struct 2010, vol. 527, pp. 3064-3072.

M. Moore, W. Evans, SAE Tech P 1958, vol. 66, pp. 340–345.

J. Epp and T. Hirsch, Materialwiss Werkst 2012, vol. 43, pp. 112-119.

J. Epp, H. Surm, J. Kovac, T. Hirsch and F. Hoffmann, Metall Mater Trans A 2011, vol. 42A, pp. 1205-1214.

Acknowledgments

This work was developed in the frame of the “BRAGECRIM” program (Brazilian German Cooperation Research Initiative in Manufacturing). The authors are deeply indebted to the DFG, CAPES, CNPq, and Finep for financial support and to HZB Berlin (neutron diffraction measurements). Preliminary cooperation also would not have been possible without support from the DAAD and CAPES. The neutron diffraction analysis has been supported by the European Commission under the 7th Framework Program through the Key Action: Strengthening the European Research Area, Research Infrastructures: Contract No. 226507 (NIMI3).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 15, 2013.

Rights and permissions

About this article

Cite this article

Hirsch, T.G.K., da Silva Rocha, A. & Menezes Nunes, R. Distortion Analysis in the Manufacturing of Cold-Drawn and Induction-Hardened Components. Metall Mater Trans A 44, 5806–5816 (2013). https://doi.org/10.1007/s11661-013-1952-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1952-z