Abstract

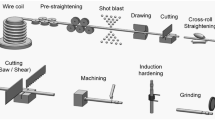

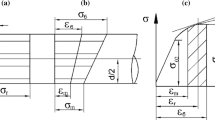

Shafts are usually manufactured from bars that are cold drawn, cut machined, induction hardened, straightened, and finally ground. The main distortion is characterized by bending that appears after induction hardening and is corrected by straightening and/or grinding. In this work, the consequence of the variation of manufacturing parameters on the distortion was analyzed for a complete manufacturing route for production of induction hardened shafts made of Grade 1045 steel. A DoE plan was implemented varying the drawing angle, cutting method, induction hardening layer depth, and grinding penetration depth. The distortion was determined by calculating curvature vectors from dimensional analysis by 3D coordinate measurements. Optical microscopy, microhardness testing, residual stress analysis, and FEM process simulation were used to evaluate and understand effects of the main carriers of distortion potential. The drawing process was identified as the most significant influence on the final distortion of the shafts.

Similar content being viewed by others

References

H W. Zoch: Proceedings 2nd Int. Conf. on distortion engineering IDE, 2008, Bremen, Germany, pp. 3–12.

Rocha AS, Nunes RM, de Souza, TF, Soares CAT, Stephan H, Tekkaya AE, Hirsch TK.: 3rd Int. Conference on distortion engineering IDE, 2011, Bremen, Germany; pp. 229–38.

Rocha AS, Nunes RM, Hirsch TK.: Materials Research, 2012, v15, pp. 266–76.

Hirsch TK, Rocha, AdaS, Nunes RM.: Metall. Mater. Trans. A 2013, 44A: 5806–16.

Rudnev V, Totten GE.: Handbook Volume 4C: Induction heating and heat treating, 2014.

Surm H, Kessler O, Hoffmann F, Mayer P.: International Journal of Materials and Product Technology, 2005, 24(1–4), pp. 270–81.

Frerichs F, Landek D, Lubben T, Hoffmann F, Zoch HW. : Materialwissenschaft und Werkstofftechnik, 2006, 37(1), pp. 63–68.

Dong J, Epp J, Rocha AS, Nunes RM, Zoch H-W, Wimpory R.: HTM J. Heat Treat. Mat, 2014, 69, pp. 348–59.

Soares CAT, Zottis J, Souza TF, Freitas LM, Colombo T, Rocha AS.: Estudos Tecnológicos em Engenharia, 2013; 9(2): pp. 54–62.

Prinz C, Hunkel M, Clausen B, Hoffmann, F, Zoch H-W: Proceedings 2nd Int. Conf. on distortion engineering IDE, 2008, Bremen, Germany, pp. 61–68

Hunkel M.: Proceedings 2nd Int. Conf. on distortion engineering IDE, 2008, Bremen, Germany, pp. 399–410

J. Dong, J. Epp, A. da S. Rocha, R. M. Nunes and H-W Zoch: Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, 2016, v 47A, pp. 877–88.

Rocha AS, Nunes RM, Metz M, Hirsch TK: Proceedings 2nd Int. Conf. On Distortion Engineering IDE, 2008, Bremen, Germany, pp. 3–12.

Acknowledgments

The authors would like to thank the funding agencies CAPES and CNPq from Brazil and DFG from Germany for the financial support for this work within the framework of the BRAGECRIM program and the HZB Berlin for the neutron measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 8, 2016.

Rights and permissions

About this article

Cite this article

Dias, V.W., da Silva Rocha, A., Zottis, J. et al. Bending Distortion Analysis of a Steel Shaft Manufacturing Chain from Cold Drawing to Grinding. Metall Mater Trans A 48, 1893–1902 (2017). https://doi.org/10.1007/s11661-016-3948-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3948-y