Abstract

Dies and tools used in hot metal forming are exposed to elevated temperatures and high contact pressures, and therefore to wear and fatigue. Fracture toughness is thus one of the main material properties used when selecting and optimizing heat treatment of tools. However, fracture toughness data alone is not sufficient and need to be supported by other material properties and features. The aim of the present research work was to correlate fracture toughness properties of hot-work tool steel, especially its variation to the local microstructure, microhardness, and composition and to establish methodology for proper evaluation of tool steel’s fracture toughness. Research was performed on H11-type hot-work tool steel specimens, heat treated under the same conditions but displaying greatly different fracture toughness. Results show that the presence of any weak point, either in a form of non-metallic inclusions and/or large undissolved eutectic carbide clusters, located in the region of positive segregation with high microhardness will lead to considerable reduction in fracture toughness.

Similar content being viewed by others

References

J.A. Schey: Tribology in Metalworking: Friction, Lubrication and Wear, ASM, Ohio, 1984.

R. Seidel and H. Luig: in Proc. Int. Eur. Conf. Tool. Mater. H. Berns, M. Hofmann, L.A. Norström, K. Rasche, and A.M. Schindler, eds., Interlaken, Switzerland, 1992, pp. 467–80.

O. Barrau, C. Boher, C. Vergne, and F. Rezai-Aria: in Proc. 6th Int. Tool. Conf. J. Bergstrom, G. Fredriksson, M. Johansson, O. Kotik, and F. Thuvander, eds., Karlstad, Sweden, 2002, pp. 81–94.

O. Barrau, C. Boher, R. Gras and F.A. Reazai: Wear, 2003, Vol. 255, pp. 1444-1454.

P.H. Hansen: Ph. D. Thesis, Technical University of Denmark, Lyngby, 1990.

R. Ebara and K. Kubota: Eng. Fail. Anal., 2008, Vol. 15, pp. 881-893.

L. Lavtar, T. Muhic, G. Kugler and M. Tercelj: Eng. Fail. Anal., 2011, Vol. 18, pp. 1143-1152.

M. Bayramoglu, H. Polat and N. Geren: J. Mater. Process. Technol., 2008, Vol. 205, pp. 394-403.

H. Saiki, Y. Marumo, A. Minami and T. Sonoi: J. Mater. Process. Technol., 2001, Vol. 113, pp. 22-27.

M. Bahrami, S.H. Mousavi, M.A. Golozar, M. Shamanian and N. Varahram: Wear, 2004, Vol. 258, pp. 846-851.

V. Leskovsek, B. Sustarsic and G. Jutrisa: J. Mater. Process. Technol., 2006, Vol. 178, pp. 328-334.

V. Leskovsek, B. Ule and B. Liscic: J. Mater. Process. Technol., 2002, Vol. 127, pp. 298-308.

H. Jesperson: in Proc. 5th Int. Conf. Tool., F. Jeglitsch, R. Ebner, and H. Leitner, eds., Leoben, Austria, 1999, pp. 93–102.

R. Ebner, H. Leitner, F. Jeglitsch, and D. Caliskanoglu: in Proc. 5th Int. Conf. Tool., F. Jeglitsch, R. Ebner, and H. Leitner, eds., Leoben, Austria, 1999, pp. 3–12.

M. Janssen, J. Zuidema and R.J.H. Wanhill: Fracture Mechanics, 2nd ed., Delft University Press, Delft, 2002.

B.A. Behrens, E. Doege, S. Reinsch, K. Telkamp. H. Daehndel and A. Specker: J. Mater. Process. Technol., 2007, Vol. 185, pp. 139-146.

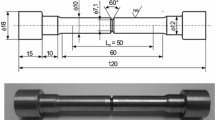

ASTM E399-12e1 Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness K Ic of Metallic Materials, ASTM, 2012.

ASTM E1820-11e2 Standard Test Method for Measurement of Fracture Toughness. ASTM, West Conshohocken, 2011.

V. Leskovsek and B. Podgornik: Mater. Sci. Eng. A, 2012, Vol. 531, pp. 119-129.

W. Chang: Eng. Fract. Mech., 1988, Vol. 31, pp. 807-816.

W. Chang: Eng. Fract. Mech., 1990, Vol. 36, pp. 313-320.

B. Ule, V. Leskovsek and B. Tuma: Eng. Fract. Mech., 2000, Vol. 65, pp. 559-572.

V. Leskovsek, B. Ule and A. Rodic: Met. Alloys Technol., 1993, Vol. 27, pp. 195-204.

S. Wei, Z. Tingshi, G. Daxing, L. Dunkang, L. Poliang and Q. Xiaoyun: Eng. Fract. Mech., 1982, Vol. 16, pp. 69-82.

M.A.N. Shabara, A.A. El-Domiaty and M.D. Al-Ansary: Eng. Fract. Mech., 1988, Vol. 54, pp. 533-541.

R.O. Ritchie and R.M. Horn: Metall. Trans. A, 9A, 1978, pp. 331-341.

K.H. Schwalbe: Eng. Fract. Mech., 1977, Vol. 9, pp. 795-832.

U. Krupp: Fatigue Crack Propagation in Metals and Alloys: Microstructural Aspects and Modelling Concepts, Wiley-VCH GmbH & Co, Weinheim, 2007.

E.E. Gdoutos: Fracture Mechanics Criteria and Applications, Kluwer Academic Publishers, London, 1990.

J.F. Knott: Fundamentals of fracture mechanics, Butterworth, London, 1973.

B. Ule: Mater. Techn., 2005, Vol. 39, pp. 189-209.

Acknowledgments

This investigation was part of a bigger project financially supported by Slovenian steel company Metal Ravne d.o.o. Involvement of Mr. A. Vrečič and Mrs. T. Vrečko-Pirtovšek, M.Sc. from Metal Ravne is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 21, 2013.

Rights and permissions

About this article

Cite this article

Podgornik, B., Leskovšek, V. Microstructure and Origin of Hot-Work Tool Steel Fracture Toughness Deviation. Metall Mater Trans A 44, 5694–5702 (2013). https://doi.org/10.1007/s11661-013-1921-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1921-6