Abstract

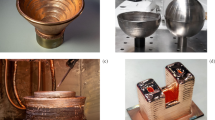

This letter introduces a method for designing hierarchical cellular metals employing multipass accumulative bundle extrusion and selective dissolving. The method provides several degrees of freedom for manipulating both the cell-wall properties and architecture of cellular materials. Cellular copper was produced and analyzed as an example of implementing the proposed method. The material hierarchy that can be formed and controlled by means of multipass accumulative extrusion assures strength and enables the material to perform the prescribed functions.

Similar content being viewed by others

References

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties, Cambridge University Press, Cambridge, 1997.

D. N. Lee and H. S. Kim: Powder Metall., 1992, vol. 35, pp. 275–79.

H. Utsunomiya, H. Koh, J. Miyamoto, and T. Sakai: Adv. Eng. Mater., 2008, vol. 10, pp 826–29.

R. Lakes: Nature, 1993, vol. 361, pp. 511–15.

C.M. Taylor, C.W. Smith, W. Miller, and K.E. Evans: Int. J. Solids Struct., 2010, vol. 48, pp. 1330–39.

A.G. Evans, J.W. Hutchinson, N.A. Fleck, M.F. Ashby, and H.N.G. Wadley: Prog. Mater. Sci., 2001, vol. 46, 309–27.

N.M. Pugno and A. Carpinteri: Philos. Mag. Lett., 2008, vol. 88, pp. 397–405.

M.J. Silva and L.J. Gibson: Int. J. Mech. Sci., 1997, vol. 39, pp. 549–63.

F.P. Levi: J. Appl. Phys., 1960, vol. 320, pp. 1469–71.

L. Thilly, F. Lecouturier, G. Coffe, J. P. Peyrade, and S. Askénazy: Physica B, 2001, vol. 294–295, pp. 648–52.

V. Vidal, L. Thilly, F. Lecouturier, and P. O. Renault: Scripta Mater., 2007, vol. 57, pp. 245–48.

M. Thirumurugan, S. A. Rao, S. Kumaran, and T. S. Rao: J. Mater. Process. Technol., 2011, vol. 211, pp. 1637–42.

T. Lee, C. H. Park, S. Y. Lee, I. H. Son, D. L. Lee, and C. S. Lee: Met. Mater. Int., 2012, vol. 18, pp. 391–96.

Y. Kimura, T. Inoue, F. Yin, and K. Tsuzaki: Science, 2008, vol. 320, pp. 1057–60.

T. Marr, J. Freudenberger, D. Seifert, H. Klauss, J. Romberg, I. Okulov, A. Eschke, C-G. Oertel, W. Skrotzki, U. Kuehn, J. Eckert, and L. Schultz: Metals, 2011, vol. 1, pp. 79–97.

T.L. Warren: J. Appl. Phys., 1990, vol. 67, pp. 7591–94.

M. Raney: US Patent #1,628,190, 1927.

T. Wada, K. Yubuta, A. Inoue, and H. Kato: Mater. Lett., 2011, 65, pp. 1076–78.

G. Gottstein and U. F. Kocks: Acta Metall., 1983, vol. 31, pp. 175–88.

C. M. Taylor, C. W. Smith, W. Miller, and K. E. Evans: Compos. Struct., 2012, vol. 94, pp. 2296–2305.

A. Ajdari, P. Canavan, H. Nayeb-Hashemi, and G. Warner: Mater. Sci. Eng. A, 2009, vol. 499, pp. 434–39.

C.C. Bampton: US Patent #5,620,537, 1997.

K. M. Ryu, J. Y. An, W. S. Cho, Y. C. Yoo, and H. S. Kim: Mater. Trans., 2005, vol. 46, pp. 622–25.

H. Gilani, S. Jafari, R. Gholami, A. Habibolahzadeh, and M. Mirshahi: Met. Mater. Int., 2012, vol. 18, pp. 327–33.

B. H. Son, J. G. Hong, Y. T. Hyun, S. C. Bae, and S. E. Kim: J. Korean Inst. Met. Mater., 2012, vol. 50, pp. 100–06.

The authors are grateful to Dr. Maxim Yutkin and Dr. Sergey Sapchenko for discussions at the early stages of the current study. The current study was supported by a grant from the Fundamental R&D Program for Core Technology of Materials (10037206) funded by the Ministry of Knowledge Economy, Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 20, 2012.

Rights and permissions

About this article

Cite this article

Latypov, M.I., Lee, D.J., Jeong, HG. et al. Design of Hierarchical Cellular Metals Using Accumulative Bundle Extrusion. Metall Mater Trans A 44, 4031–4036 (2013). https://doi.org/10.1007/s11661-013-1844-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1844-2