Abstract

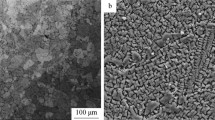

Stress rupture behavior and microstructure evolution of nickel-based superalloy Waspaloy specimens from tenon teeth of an as-received 60,000-hour service-exposed gas turbine disk were studied between 923 K and 1088 K (650 °C and 815 °C) under initial applied stresses varying from 150 to 840 MPa. Good microstructure stability and performance were verified for this turbine disk prior to stress rupture testing. Microstructure instability, such as the coarsening and dissolution of γ′ precipitates at the varying test conditions, was observed to be increased with temperature and reduced stress. Little microstructure variation was observed at 923 K (650 °C). Only secondary γ′ instability occurred at 973 K (700 °C). Four fracture mechanisms were obtained. Transgranular creep fracture was exhibited up to 923 K (650 °C) and at high stress. A mixed mode of transgranular and intergranular creep fracture occurred with reduced stress as a transition to intergranular creep fracture (ICF) at low stress. ICF was dominated by grain boundary sliding at low temperature and by the nucleation and growth of grain boundary cavities due to microstructure instability at high temperature. The fracture mechanism map and microstructure-related fracture model were constructed. Residual lifetime was also evaluated by the Larson–Miller parameter method.

Similar content being viewed by others

Notes

Waspaloy is a trademark of Special Metals Corporation, New Hartford, NY.

References

S.L. Semiatin, P.N. Fagin, M.G. Glavicic and D. Raabe: Scripta Mater., 2004, vol. 50, pp. 625-29.

Z.H. Yao, J.X. Dong and M.C. Zhang: Acta Metall. Sin., 2011, vol. 12, pp. 1581-90.

M. Gao and R.P. Wei: Scripta Metall., 1994, vol. 30 (8), pp. 1009-14.

M. Brogdon and A.H. Rosenberger: Superalloys 2008, R.C. Reed, K.A. Green, P. Caron, T.P. Gabb, M.G Fahrmann, E.S. Huron, and S.A. Woodard, eds., TMS, Warrendale, PA, 2008, pp. 583–88.

V.S.K.G. Kelekanjeri, L.K. Moss, R.A. Gerhardt and J. Ilavsky: Acta Mater., 2009, vol. 57, pp. 4658-70.

R.J. Moat, A.J. Pinkerton, L. Li, P.J. Withers, and M. Preuss: Mater. Sci. Eng. A, 2011, 528 (6), pp. 2288–98.

V.S. Kumar, G. Kelekanjeri and R.A. Gerhardt: Electrochim. Acta, 2006, vol. 51, pp. 1873-80.

K. Tokoro, N.P. Wikstrom, O.A. Ojo, and M.C. Chaturvedi: Mater. Sci. Eng. A, 2008, vol. 477, pp. 311–18.

A. Chamanfar, M. Jahazi, J. Gholipour, P. Wanjara, and S. Yue: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 729–44.

V.S.K. Kelekanjeri and R.A. Gerhardt: Acta Mater., 2009, vol. 57, pp. 616-27.

J. Tsang, R.M. Kearsey, P. Au, D. Seo, S. Oppenheimer and W. Cao: Mater. High Temp., 2010, vol. 27, pp. 79-88.

B. Wilshire and P.J. Scharning: Mater. Sci. Technol., 2009, vol. 25, pp. 242-48.

M.P. Jackson and R.C. Reed: Mater. Sci. Eng. A, 1999, vol. 259, pp. 85–97.

X.Liu and B. Kang: Mater. Sci. Eng. A, 2003, vol. 340, pp. 8–14.

J. Busby: Metall. Met. Form., 1972, pp. 325–28.

L. Liu, F. Sommer and H.Z. Fu: Scripta Metall. Mater., 1994, vol. 30 (5), pp. 587-91.

T.J. Garosshen and G.P. McCarthy: Metall. Trans. A, 1985, vol. 16A, pp. 1213–23.

R.A. Stevens and P.E.J. Flewitt: Mater. Sci. Eng., 1979, vol. 37 A, pp. 237–47.

A.K. Koul and R. Castillo: Metall. Trans. A, 1988, vol. 19A, pp. 2049–66.

W. Sha: Scripta Mater., 2000, vol. 42, pp. 549-53.

C.M.F. Rae and R.C. Reed: Acta Mater., 2001, vol. 49, pp. 4113-25.

X.Z. Qin, J.T. Guo, C. Yuan, C.L. Chen, J.S. Hou and H.Q. Ye: Mater. Sci. Eng., 2008, vol. 485 (25) A, pp. 74-79.

K.M. Chang and X.B. Liu: Mater. Sci. Eng., 2001, vol. 308 A, pp. 1-8.

Y. Lindblom and G. Engberg: in High Temperature Alloys for Gas Turbines, R. Brunetard, D. Coutsouradis, T.B. Gibbons, Y. Lindblom, D.B. Meadowcroft and R. Stickler, eds., D. Reidel, Dordrecht, 1982, pp. 447–54.

W.L. Kimmerle, J.K. Tien and W.H. Couts: Scripta Metall., 1987, vol. 21, pp. 1553-57.

T.H. Hyde, L. Xia, A.A. Becker and W. Sun: Fatigue Fract. Eng. Mater. Struct., 1997, vol. 20, pp. 1295-03.

C.G. McKamey and E.P. George: Creep Fract. Eng. Mater. Struct., The Institute of Materials, London, 2001, pp. 393–99.

H. J. Frost and M. F. Ashby: Deformation-Mechanism Maps, Pergamon Press, Elmsford, NY, 1982.

D. Teirlinck, F. Zok, J.D. Embury and M.F. Ashby: Acta Metall., 1988, vol. 36, pp. 1213-28.

A.N. Stroh: Proc. R. Soc., London A, 1954, vol. 223, pp. 404–14.

D.A. Curry: Met. Sci., 1980, vol. 14, pp. 319-26.

R. R. Unocic, G. B. Viswanathan, P. M. Sarosi, S. Karthikeyan, J. Li and M. J. Mills: Mater. Sci. Eng., 2008, vol. A483-484, pp. 25-32.

A. Epishin, T. Link, H. Harada, Y. Koizumi, and T. Kobayashi: Superalloys 2004, K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, S. Walston, eds., The Minerals, Metals and Materials Society, 2004, pp. 137–143.

Y. Yuan, Y. F. Gu, C. Y. Cui, T. Osada, T. Tetsui, T. Yokokawa, and H. Harada: Mater. Sci. Eng., 2011, vol. 528 A, pp. 5106–11.

J. X. Zhang, T. Murakumo, H. Harada, Y. Koizumi, and T. Kobayashi: Superalloys 2004, K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, S. Walston, eds., The Minerals, Metals and Materials Society, 2004, pp. 189–95.

K. Kakehi: Mater. Sci. Eng. A, 2000, vol. 278 A, pp. 135–41.

H.J. Penkalla, J. Wosik and A.C. Filemonowicz: Mater. Chem. and Phys., 2003, vol. 81, pp. 417-23.

J. Wosik, B. Dubiel, A. Kruk, H.J. Penkalla, F. Schubert and A. C. Filemonowicz: Mater. Charact., 2001, vol. 46, pp. 119-23.

F. D. Rosi and F. C. Perkins: J. Metals, 1953, vol. 5, pp. 1083-84.

S.J. Zinkle and G.E. Lucas: in Fusion Materials Semi-annual Progress Report for Period ending. June 30, 2003, DOE/ER-0313/34, Oak Ridge National Laboratory, 2003, pp. 101–25.

S. Xu, X. J. Wu, A. K. Koul and J. I. Dickson: Metall. Mater. Trans., 1999, vol. 30A, pp. 1039-45.

X.J. Wu and A.K. Koul: in Creep and Stress Relaxation in Miniature Structures and Components, H.D. Merchant, ed., TMS, 1996, pp. 3–19.

X.J. Wu and A.K. Koul: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 905–14.

S. Xu, A.K. Koul, and J.I. Dickson: Metall. Mater. Trans., 2001, vol. 32 A, pp. 795-804.

A.K. Ray, Y.N. Tiwari, P.K. Roy, and S. Chaudhuri: Mater. Sci. Eng. A, 2007, vol. 454, pp. 679–84.

P. Dowson, D. Rishcl and N. Bornstcin: Proceedings of the Twenty-fourth Turomachinery symposium, Texas A&M University, Colloge station, Texas, 1995, pp. 11-26.

H. J. Kim: Eng. Failure Anal., 2005, vol. 12, pp. 578-85.

A. Kim, K. Tunvir, S.H. Nahm and S.S. Cho: J. Mater. Process. Technol., 2008, vol. 202, pp. 450-56.

Acknowledgments

The authors thank Professor X.S. Xie for his helpful and rewarding comments on the stress rupture behavior. The work presented here was funded by the National Natural Science Foundation of China (51071017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Waspaloy is a trademark of Special Metals Corporation, New Hartford, NY.

Manuscript submitted January 27, 2011.

Rights and permissions

About this article

Cite this article

Yao, Z., Zhang, M. & Dong, J. Stress Rupture Fracture Model and Microstructure Evolution for Waspaloy. Metall Mater Trans A 44, 3084–3098 (2013). https://doi.org/10.1007/s11661-013-1660-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1660-8