Abstract

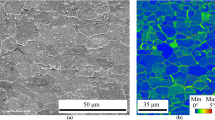

The impact response and microstructural evolution of 316L stainless steel are examined at strain rates ranging from 1 × 103 to 5 × 103 s−1 and temperatures between 298 K and 1073 K (25 °C and 800 °C) using a split Hopkinson pressure bar and transmission electron microscopy (TEM). The results show that the flow behavior, mechanical strength, and work-hardening properties of 316L stainless steel are significantly dependent on the strain rate and temperature. The TEM observations reveal that the dislocation density increases with increasing strain rate but decreases with increasing temperature. Moreover, twinning occurs only in the specimens deformed at 298 K (25 °C), which suggests that the threshold stress for twinning is higher than that for slip under impact loading. Finally, it is found that the volume fraction of transformed α′ martensite increases with increasing strain rate or decreasing temperature. Overall, the results suggest that the increased flow stress observed in 316L stainless steel under higher strain rates and lower temperatures is determined by the combined effects of dislocation multiplication, twin nucleation and growth, and martensite transformation.

Similar content being viewed by others

References

R.A. Luna, J.G. Parr, and A. Hanson: Stainless Steel, ASM, Materials Park, OH, 1986, pp. 60–70.

S.G. Hong and S.B. Lee: Int. J. Fatigue, 2004, vol. 26, pp. 899–910.

M.C. Mataya, E.R. Nilsson, E.L. Brown, and G. Krauss: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1683–1703.

M.F. Abbod, C.M. Sellars, A. Tanaka, D.A. Linkens, and M. Mahfouf: Mater. Sci. Eng. A, 2009, vol. A491, pp. 290–96.

E. Otero, A. Pardo, M.V. Utrilla, E. Saenz, and J.F. Alvarez: Corros. Sci., 1988, vol. 40, pp. 1421–34.

W.S. Lee and T.J. Liu: J. Nucl. Mater., 2006, vol. 359, pp. 247–57.

R. Liang and A.S. Khan: Int. J. Plastic., 1999, vol. 15, pp. 963–80.

W.S. Lee, C.F. Lin, T.H. Chen, and H.H. Huang: J. Mech. Behav. Biomed., 2008, vol. 1, pp. 336–44.

G. Regazzoni, U.F. Kocks, and P.S. Follansbee: Acta Metall., 1987, vol. 35, pp. 2865–75.

W.S. Lee, C.F. Lin, T.H. Chen, and M.C. Yang: Mater. Sci. Eng. A, 2010, A527, pp. 3127–37.

P.S. Follansbee and U.F. Kocks: Acta Metall., 1988, vol. 36, pp. 81–93.

W.S. Lee and C.F. Lin: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2801–10.

X. Feaugas: Acta Mater., 1999, vol. 37, pp. 3617–32.

K. Yasunaga, M. Iseki, and M. Kiritanii: Mater. Sci. Eng. A, 2003, vol. A350, pp. 76–80.

H. Jarmakani, J.M. McNaney, B. Kad, D. Orlikowshi, J.H. Nguyen, and M.A. Meyers: Mater. Sci. Eng. A, 2007, vol. A463, pp. 249–62.

M.E. Kassner: Acta Mater., 2004, vol. 52, pp. 1–9.

M. Blicharski and S. Gorczyca: Met. Sci., 1978, vol. 12, pp. 303–12.

F. Greulich and L.E. Murr: Mater. Sci. Eng., 1979, vol. 39, pp. 81–93.

W.S. Lee and C.F. Lin: Metall. Trans., 2001, vol. 42, pp. 2080–86.

G.G. Yapici, I. Karaman, and Z.P. Luo: Acta Mater., 2006, vol. 54, pp. 3755–71.

A.J. W. Johnson, C.W. Bull, K.S. Kumar, and C.L. Briant: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 295–306.

S.K. Varma, J. Kalyanam, L.E. Murr, and V. Srinivas: J. Mater. Sci. Lett., 1994, vol. 13, pp. 107–11.

J.Y. Choi and W. Jin: Scripta Mater., 1997, vol. 36, pp. 99–104.

S.S. Hecker, M.G. Stout, K.P. Staudhammer, and J.L. Smith: Metall. Trans. A, 1982, vol. 13A, pp. 619–26.

W.S. Lee, T.H. Chen, C.F. Lin, and W.Z. Luo: Bioinorg. Chem. Appl., 2011, vol. 2011, p. 173782.

W. Osterle: Prakt. Metallogr., 1992, vol. 29, pp. 401–13.

R.K. Ham: Philos. Mag., 1961, vol. 6, pp. 1183–84.

J. Litonski: Bull. Acad. Pol. Sci. Ser. Sci. Technol., 1977, vol. 25, pp. 7–14.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng. A, 2004, vols. A387–89, pp. 158–62.

A. Rohatgi, K.S. Vecchio, and G.T. Gray III: Metall. Mater. Trans. A, 2001, vol. 32A, pp.135–45.

M.F. de Campos, S.A. Loureiro, D. Rodrigues, M.C.A. da Silra, and N.B. de Lima: Mater. Sci. Forum, 2008, vols. 591–93, pp. 3–7.

W.S. Lee, T.H. Chen, and S.C. Huang: J. Nucl. Mater., 2010, vol. 402, pp. 1–7.

W.S. Lee, C.F. Lin, T.H. Chen, and M.C. Yang: Mater. Sci. Eng. A, 2010, vol. A527, pp. 3127–37.

L.E. Murr: Shock Waves and High-Strain-Rate Phenomena in Metals, M. A. Meyers and L.E. Murr, eds., Plenum Press, New York, NY, 1981, pp. 607–73.

D.R. Chichili, K.T. Ramesh, and K.J. Hemker: Acta Mater., 1998, vol. 46, pp. 1025–43.

Acknowledgments

The authors gratefully acknowledge the financial support provided to this study by the National Science Council of the Republic of China under Grant No. NSC99-2221-E-006-020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 18, 2011.

Rights and permissions

About this article

Cite this article

Lee, WS., Chen, TH., Lin, CF. et al. Impact Response and Microstructural Evolution of 316L Stainless Steel under Ambient and Elevated Temperature Conditions. Metall Mater Trans A 43, 3998–4005 (2012). https://doi.org/10.1007/s11661-012-1233-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1233-2