Abstract

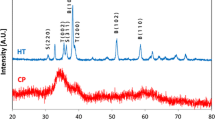

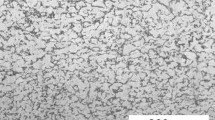

The microstructural evolution of compound layers grown on 1-mm thick α-iron substrates after nitrocarburizing at 853 K (580 °C) in NH3/H2/N2/CO gas mixtures was investigated by light optical microscopy and X-ray diffraction. The evolution of the microstructure can be divided into several stages. Starting with the formation of the carbon-rich phase cementite, which practically does not contain nitrogen, the phase constitution of the compound layer develops through successive stages of microstructural change into the direction of the nitrogen-richer and carbon-poorer phases ε and γ’. These results are the consequences of (1) the kinetics of nitrogen and carbon uptake at the gas–solid interface and the considerably different solubilities of nitrogen and carbon in the α-iron substrate and (2) the occurrence of local equilibrium conditions prevailing at the solid–solid interphase boundaries in the compound layer. The change of the microstructure as a function of depth in the compound layer is shown to be compatible with so-called “diffusion paths” in the ternary Fe-N-C phase diagram.

Similar content being viewed by others

Notes

Inhomogeneous means that the phase constitution of the microstructure and, thus, the composition in the compound layer varies as function of the lateral position on the specimen cross section. According to the current observations, the position/height of the specimen in the furnace did not influence the distribution of the different microstructures: The linear gas flow rates in the furnace are high enough so that the effective chemical potentials of N and C are constant along the surface of the specimen during the heat treatment.

A time-invariant phase constitution (microstructure) of the compound layer is expected to occur only for the case of a constant nitrogen and carbon concentration at the surface of the compound layer (implying local equilibrium or stationary state at the gas–solid interface) in combination with (1) a nitrogen and carbon saturated substrate or (2) an infinitely thick substrate with initially constant nitrogen and carbon content. In such cases (and assuming local equilibrium at the solid–solid interfaces in the compound layer), the so-called Boltzmann transformation can be applied to Fick’s second law, implying a time-invariant diffusion path (lateral gross composition as a function of depth) and a parabolic growth of the compound-layer thickness.[4,7,35]

For example, if the recombination and desorption of adsorbed nitrogen atoms from the specimen surface cannot be neglected compared with the rate of NH3 dissociation, a stationary state instead of a local equilibrium occurs, i.e., the chemical potential of nitrogen in the solid at the surface of the specimen is lower than that pertaining to the nitrocarburizing atmosphere.[12,36]

Even in the case of finite but about equal transfer rates of nitrogen and carbon, the solubility limit of carbon will be surpassed first as a consequence of the large difference of the solubility limits of nitrogen and carbon.

“Metastable” because θ, ε, and γ’ are considered not to decompose into graphite, nitrogen gas, and α-Fe as required for “stable” phase equilibria.

The possible conversion of cementite into ε was first reported in Reference 39 after nitriding of pearlitic substrates at 843 K (570 °C).

Moreover, as shown in Figure 7, the formation of a single-phase γ’ layer from a cementite and/or an ε containing compound layer is possible only if the carbon content in the α-iron substrate at the layer/substrate interface is decreased.

The diffusional flux of carbon into the α-iron substrate can be neglected because of the small solubility limit of carbon in ferrite; see Table I.

References

F.J.J. Van Loo, M.R. Rijnders, K.J. Ronka, J.H. Gulpen, and A.A. Kodentsov: Solid State Ionics, 1997, vol. 95, nos. 1–2, pp. 95–106.

P.M. Unterweiser: Source Book on Nitriding, ASM, Materials Park, OH, 1977.

A.A. Kodentsov, G.F. Bastin, and F.J.J. Van Loo: J. Alloys Compd., 2001, vol. 320, pp. 207–17.

F.J.J. Van Loo: Progr. Solid State Chem., 1990, vol. 20, pp. 47–99.

J.M.G. Vilar and J.M. Rubí: Proc. Natl. Acad. Sci. U S A, 2001, vol. 98, pp. 11081–84.

Y.H. Sohn and M.A. Dayananda: Acta Mater., 2000, vol. 48, pp. 1427–33.

J.S. Kirkaldy and D.J. Young: Diffusion in the Condensated State, The Institute of Metals, London, U.K., 1987.

G. Ghosh: J. Electron. Mater., 1998, vol. 27, pp. 1154–60.

M.A.J. Somers: Heat Treat. Met., 2000, vol. 4, pp. 92–102.

J. Slycke: Nitrieren und Nitrocarburieren, AWT, Darmstadt, Germany, 1996, pp. 19–28.

M.A.J. Somers and E.J. Mittemeijer: Surf. Eng., 1987, vol. 3, pp. 123–37.

E.J. Mittemeijer and M.A.J. Somers: Surf. Eng., 1997, vol. 13, pp. 483–37.

P.F. Colijn, E.J. Mittemeijer, and H.C.F. Rozendaal: Z. Metallkd., 1983, vol. 74, pp. 620–27.

J. Slycke and L. Sproge: Surf. Eng., 1989, vol. 5, pp. 125–40.

T. Gressmann, M. Nikolussi, A. Leineweber, and E.J. Mittemeijer: Scripta Mater., 2006, vol. 55, pp. 723–26.

H. Du: J. Phase Equil., 1993, vol. 14, pp. 682–93.

J. Kunze: Nitrogen and Carbon in Iron and Steel, Akademie-Verlag Berlin, Germany, 1990.

T. Bell: Heat Treat. Met., 1975, vol. 2, pp. 39–49.

C. Dawes and D.F. Tranter: Heat Treat. Met., 1985, vol. 3, pp. 70–76.

T. Bell and D.H. Thomas: Metall. Trans. A, 1979, vol. 10A, pp. 79–84.

E.J. Mittemeijer: J. Heat Treat., 1983, vol. 3, pp. 114–19.

M.A.J. Somers, P.F. Colijn, W.G. Sloof, and E.J. Mittemeijer: Z. Metallkd., 1990, vol. 81, pp. 33–43.

H. Du, M.A.J. Somers, and J. Ågren: Metall. Mater. Trans. A 2000, vol. 31A, pp. 195–211, 801.

M. Nikolussi, A. Leineweber, E. Bischoff, and E.J. Mittemeijer: Int. J. Mater. Res., 2007, vol. 98, pp. 1086–92.

T. Woehrle, A. Leineweber, and E.J. Mittemeijer: HTM J. Heat Treat. Mater., 2010, vol. 65, pp. 243–48.

M. Nikolussi, A. Leineweber, and E.J. Mittemeijer: J. Mater. Sci. 2009, vol. 44, pp. 770–77.

E. Lehrer: Z. Elektrochem., 1930, vol. 36, pp. 383–92.

S.S. Hosmani, R.E. Schacherl, and E.J. Mittemeijer: Acta Mater., 2006, vol. 54, pp. 2783–92.

H.A. Wriedt, N.A. Gokcen, and R.H. Nafziger: Bull. Alloy. Phase. Diagr., 1987, vol. 8, pp. 355–77.

A. Wells: J. Mater. Sci., 1985, vol. 20, pp. 2439–45.

G. Petzow: Metallographic Etching, ASM International, Materials Park, OH, 1999.

M. Nikolussi, A. Leineweber, and E.J. Mittemeijer: Phil. Mag., 2010, vol. 90, pp. 1105–22.

M.A.J. Somers and E.J. Mittemeijer: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 57–74.

T. Sone, E. Tsunasawa, and K. Yamanaka: Trans. Japan Inst. Met., 1981, vol. 22, pp. 237–43.

J. Crank: The Mathematics of Diffusion, Oxford Science Publications, Oxford, U.K., 1975.

E.J. Mittemeijer and J.T. Slycke: Heat Treat. Met., 1996, vol. 3, pp. 67–71.

H.J. Grabke: Archiv Eisenhütten., 1975, vol. 46, pp. 75–81.

M. Weller: Mater. Sci. Forum, 2001, vols. 366–368, p. 95.

E.J. Mittemeijer, W.T.M. Straver, P.F. Colijn, P.J. van der Schaaf, and J.A. van der Hoeven: Scripta Metall., 1980, vol. 14, pp. 1189–92.

J. Kunze: Härterei-Tech. Mitt., 1996, vol. 51, pp. 348–55.

J. Slycke, L. Sproge, and J. Ågren: Scand. J. Metall., 1988, vol. 17, pp. 122–26.

H. Du and J. Ågren: Z. Metallkd., 1995, vol. 86, pp. 522–29.

Acknowledgment

The authors are grateful to Dr. Thomas Gressmann for his help with the nitrocarburizing experiments and the scientific discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 7, 2011.

Rights and permissions

About this article

Cite this article

Woehrle, T., Leineweber, A. & Mittemeijer, E.J. Microstructural and Phase Evolution of Compound Layers Growing on α–Iron During Gaseous Nitrocarburizing. Metall Mater Trans A 43, 2401–2413 (2012). https://doi.org/10.1007/s11661-012-1100-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1100-1