Abstract

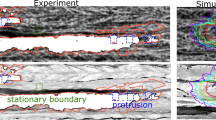

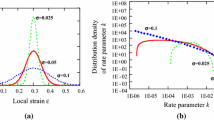

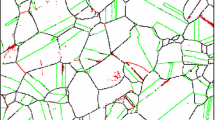

The kinetics and microstructure of the static recrystallization of strongly deformed, pure copper were investigated based on a comparison of mesoscopic, cellular automata simulations with experimental data. Physical models for the nucleation rate and the growth rate of recrystallized grains were employed, which required experimentally obtained informations about the deformed state as input. The orientation-distribution function and the misorientation-angle distribution for neighboring grains of deformed specimens were used to set up the microstructure serving as the start configuration for the simulations. The influences of a subgrain-size distribution, of an ongoing nucleation during recrystallization, of an inhomogeneously distributed stored energy in the deformed state, and of a misorientation-dependent interface mobility were investigated. The simulated microstructures after recrystallization exhibit a bimodal grain-size distribution instead of the broad, monomodal grain-size distribution found in the experiments. It is argued that spatially resolved determination of crystal (subgrain) orientation and (deformation) energy is necessary to arrive at realistic descriptions of both the recrystallization kinetics and the microstructure after completed recrystallization.

Similar content being viewed by others

Notes

The small features in deformed microstructures with dislocations forming more or less well-defined walls and relatively dislocation-free interiors are referred to as subgrains or dislocation cells in the literature. To avoid confusion between the “cells” in a deformed microstructure and the “cells” in a cellular automaton simulation, the term “subgrains” will be used for the former throughout this article.

A different model for “discontinuous subgrain coarsening” assumes that the subgrain-size criterion is fulfilled for most subgrains but that they only have immobile, low-angle grain boundaries with their neighbors. Normal subgrain growth then leads to a situation in which individual subgrains can obtain mobile, high-angle grain boundaries with their neighbors, e.g., by continuous merging of low-angle grain boundaries[8,9] and then start to grow, i.e., coarsen discontinuously.[33]

A range of values from β = 2 to 5 has been observed experimentally.[9] A sensitivity study concerning this parameter has been performed in this work, and it was found that a variation of the value of β in this range does not change the simulation results qualitatively and, thereby, the conclusions drawn.

Note that this explanation for a decreasing (average) interface velocity during recrystallization applies only if the regions with high and low deformation energy are spatially distributed randomly in the specimen and if the length scale of the stored-energy inhomogeneity is of the same order of magnitude as the size of the recrystallizing grains. If it is (much) smaller, then each recrystallizing grain sweeps through (very) many regions of different stored energy, and thus, the average interface velocity is constant throughout the recrystallization (see also the discussion in Ref. 11)

It has also been argued that the crystal-lattice orientation with respect to the specimen frame of reference, and not the misorientation between recrystallizing grain and deformed matrix, is responsible for the high growth rate of certain grains,[7] i.e., grains belonging to certain texture components have an inherently higher growth rate.

Note that the geometrical simulation is used here merely to create a space-filling structure and not to model the development of subgrains physically.

Not to be confused with the subgrains/cells of the simulated and real microstructures; see footnote in Section I.

The stored energy, which is the driving force \((-\Updelta G)\) of the recrystallization, can be taken as approximately equal to the enthalpy released \((-\Updelta H)\) during recrystallization.[45]

Note that the average size of the recrystallization nuclei is larger than the average subgrain size because (only) the large (\(r_i>r^\ast\)) subgrains act as recrystallization nuclei.

References

K.W. Mahin, K. Hanson, J.W. Morris, Acta Metall., 28, 443–53 (1980)

T.O. Sætre, O. Hunderi, E. Nes, Acta Metall., 34, 981–87 (1986)

D.J. Srolovitz, G. Grest, M.P. Anderson, Acta Metall., 34, 1833 (1986)

W.A. Johnson, R.F. Mehl, Trans. Am. Inst. Min. Metal. Eng., 135, 416–42 (1939)

M. Avrami, J. Chem. Phys., 7, 1103–12 (1939)

A.N. Kolmogorov, Izv. Akad. Nauk SSSR Ser. Mat., 1, 355–59 (1937)

D. Juul Jensen, Acta Metall. Mater., 11, 4117–29 (1995)

E.J. Mittemeijer, Fundamentals of Materials Science. (Springer Verlag, Berlin, Germany, 2010)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena. 2nd ed. (Elsevier, Amsterdam, The Netherlands, 2004)

E. Woldt, Metall. Mater. Trans. A, 32A, 2465–73 (2001)

T. Furu, K. Marthinsen, E. Nes, Mater. Sci. Tech., 6, 1093–1102 (1990)

E. Fjeldberg, K. Marthinsen, Comp. Mater. Sci., 48, 267 (2010)

K. Marthinsen, O. Lohne, E. Nes, Acta Metall., 37, 135–45 (1989)

H.S. Zurob, Y. Bréchet, J. Dunlop, Acta Mater., 54, 3983–90 (2006)

R.D. Doherty, Solid-to-Solid Phase Transformations in Inorganic Materials, J.M. Howe, D.E. Laughlin, J.K. Lee, U. Dahmen, and W.A. Soffa, eds., vol. 1, TMS, Warrendale, PA, 2005.

A. Brahme, J.M. Fridy, H. Weiland, A.D. Rollett, Model. Simul. Mater. Sci. Eng., 17, 015005 (2009)

Y.S. Seo, Y.B. Chun, S.K. Hwang, Comp. Mater. Sci., 43, 512 (2008)

Y. Suwa, Y. Saito, H. Onodera, Comp. Mater. Sci., 44, 286–95 (2008)

D. Raabe, R. Becker, Model. Simul. Mater. Sci. Eng., 8, 445 (2000)

B. Radhakrishnan, G. Sarma, T. Zacharia, Acta Mater., 46, 4415–33 (1998)

T. Takaki, Y. Tomita, Int. J. Mech. Sci., 52, 320 (2010)

E.A. Jägle and E.J. Mittemeijer, Metall. Mater. Trans. A, 43A, 1117–31 (2012)

Y.B. Chun, S.L. Semiatin, S.K. Hwang, Acta Mater., 54, 3673–89 (2006)

D. Juul Jensen, Metall. Mater. Trans. A, 28A, 15–25 (1997)

D. Weygand, Y. Bréchet, J. Lepinoux, Interface Sci., 9, 311 (2001)

A.D. Rollett, D.J. Srolovitz, R.D. Doherty, M.P. Anderson, Acta Metall., 37, 627–39 (1989)

H.W. Hesselbarth, I.R. Göbel, Acta Metall. Mater., 39, 2135–43 (1991)

K.G.F. Janssens, Model. Simul. Mater. Sci. Eng., 11, 157 (2003)

D. Raabe, Annu. Rev. Mater. Res., 32, 53 (2002)

C. Bos, M. Mecozzi, J. Sietsma, Comp. Mater. Sci., 48, 692–99 (2010)

Y. Bréchet, G. Martin, Comptes Rendus Phys., 7, 959–76 (2006)

F. Liu, F. Sommer, C. Bos, E.J. Mittemeijer, Int. Mater. Rev., 52, 193–212 (2007)

E.A. Holm, M.A. Miodownik, A.D. Rollett, Acta Mater., 51, 2701–16 (2003)

E. Woldt, D. Juul Jensen, Metall. Mater. Trans. A, 26A, 1717–24 (1995)

J.W. Cahn, Acta Metall., 4, 449–59 (1956)

R.A. Vandermeer, D. Juul Jensen, Mater. Sci. Forum, 467–470, 193–96 (2004)

E.A. Jägle, E.J. Mittemeijer, Solid State Phenom., 172–174, 1128–33 (2011)

S. Storm, D. Juul Jensen, Scripta Mater., 60, 477–80 (2009)

E.A. Jägle, E.J. Mittemeijer, Acta Mater., 59, 5775–86 (2011)

R.A. Vandermeer, D. Juul Jensen, Metall. Mater. Trans. A, 26A, 2227–35 (1995)

E.A. Jägle, E.J. Mittemeijer, Model. Simul. Mater. Sci. Eng., 18, 065010 (2010)

A. Getis, B. Boots, Models of Spatial Processes. (Cambridge University Press, Cambridge, U.K., 1978)

M. Miodownik, A.W. Godfrey, E.A. Holm, D.A. Hughes, Acta Mater., 47, 2661 (1999)

W.H. Press, B.P. Flannery, S.A. Teukolsky, W.T. Vetterling, Numerical Recipes. (Cambridge University Press, Cambridge, U.K., 1986)

J.W. Christian, The Theory of Transformations in Metals and Alloys. 3rd ed. (Pergamon, Oxford, U.K, 2002)

V. Marx, F. Reher, G. Gottstein, Acta Mater., 47, 1219–30 (1999)

J.K. Mackenzie, Biometrika, 45, 229–40 (1958)

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 20, 2011.

Rights and permissions

About this article

Cite this article

Jägle, E.A., Mittemeijer, E.J. Interplay of Kinetics and Microstructure in the Recrystallization of Pure Copper: Comparing Mesoscopic Simulations and Experiments. Metall Mater Trans A 43, 2534–2551 (2012). https://doi.org/10.1007/s11661-012-1094-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1094-8