Abstract

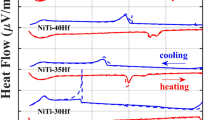

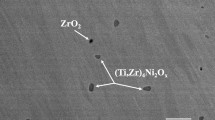

Different microstructures of Ni-Ti- and Ni-Ti-Fe-based shape memory alloys were subjected to thermal cycling: dipping in liquid nitrogen, for approximately 5 minutes, and then bringing it back to room temperature or austenite (cubic: B2) ↔ martensite (monoclinic: B19′) reversible solid-state phase transformation. Direct electron backscattered diffraction (EBSD) observations could bring out aspects of microstructural irreversibilities: namely, changes in grain size, misorientation buildup, and presence of retained martensite. The average changes in grain size (Δd) differed by almost 2 to 4 times between different microstructures. The highest Δd was typically observed in structures having maximum clustering of fine (d < 5 μm) grains. The sample with highest Δd was also subjected to multiple thermal cycling. Although Δd scaled linearly with d after the first thermal cycle, the scatter increased during subsequent thermal cycles. Grain or orientations deviating from the linear behavior were clearly anisotropic crystallographically. With repeated thermal cycling, the patterns of changes in Δd, austenite misorientation, and retained martensite content were similar. A phenomenological model or hypothesis, based on 40 deg \( \left\langle {001} \right\rangle \) orientation relationship between austenite and martensite phases, was proposed to address the observed patterns of microstructural irreversibility.

Similar content being viewed by others

References

W.A. Rachikger: J. Appl. Phys., 1958, vol. 9, pp. 250–52.

W.J. Buehler, J.V. Gilfrich, and R.C. Wiley: J. Appl. Phys., 1963, vol. 34, pp. 1475–77.

F.E. Wang, W.J. Buehler, and S.J. Pickart: J. Appl. Phys., 1965, vol. 36, pp. 3232–39.

R.J. Wasilewski, S.R. Butler, and J.E. Hanlon: Met. Sci. J., 1967, vol. 1, pp. 104–10.

F.E. Wang and W.J. Buehler: Appl. Phys. Lett., 1972, vol. 21, pp. 105–06.

C.M. Wayman and K. Shimizu: Met. Sci. J., 1972, vol. 6, pp. 175–83.

J.A. Shaw and S. Kyriakides: Acta Mater., 1997, vol. 45, pp. 683–700.

M.W.M. van der Wijst: Ph.D. Dissertation, TU Eindhoven, the Netherlands, 1992.

G.B. Kauffman and I. Mayo: Chem. Ed., 1996, vol. 2, pp. 1–21.

T.W. Duerig and A.R. Pelton: ASM Materials Properties Handbook, Titanium Alloys, ASM International, Materials Park, OH, 1994, pp. 1035–48.

J. Beyer: J. Phys. IV, 1995, vol. 5, pp. C2 433–41.

K. Madangopal: Acta Mater., 1997, vol. 45, pp. 5347–65.

K. Bhattacharya, S. Conti, G. Zanzotto, and J. Zimmer: Nature, 2004, vol. 428, pp. 55–59.

K. Otsuka and X. Ren: Prog. Mater. Sci., 2005, vol. 50, pp. 511–678.

H.S. Tzou, H.J. Lee, and S.M. Arnold: Mech. Adv. Mater. Struc., 2005, vol. 11, pp. 367–93.

T.W. Duerig: Mater. Sci. Forum, 1990, vols. 56-58, pp. 679–92.

C. Zhang and R.H. Zee: Proc. IECEC, 1996, pp. 239–44.

B. Kim, M.G. Lee, Y.P. Lee, Y.I. Kim, and G.H. Lee: Sensor Actuator, 2006, vol. A125, pp. 429–37.

A.W. Anson, D.H.R. Jenkins, and S. Andrews: Proc. Technology Transfer Workshop, ESA SP-364, 1994, pp. 73–77.

D. Mantovani: J. Min. Met. Mater. Soc., 2000, vol. 52, pp. 36–44.

T. Duerig, A. Pelton, and D. Stoeckel: Mater. Sci. Eng. A, 1999, vols. A273-5, pp. 149–60.

J.V. Humbeeck: Mater. Sci. Eng. A, 1999, vols. A273-5, pp. 134–48.

K. Gall, J. Tyber, G. Wilkesanders, S.W. Robertson, R.O. Ritchie, and H.J. Maier: Mater. Sci. Eng. A, 2008, vol. A486, pp. 389–403.

C.P. Frick, A.M. Ortega, J. Tyber, A. El. M. Maksound, H.J. Maier, Y. Liu, and K. Gall: Mater. Sci. Eng. A, 2005, vol. A405, pp. 34–49.

G. Eggeler, E. Hornbogen, A. Yawny, A. Heckmann, and M. Wagner: Mater. Sci. Eng. A, 2004, vol. A378, pp. 24–33.

N.B. Morgan and C.M. Friend: J. Phys. IV, 2001, vol. 11, pp. 325–32.

E. Hornbogen: J. Mater. Sci., 2004, vol. 39, pp. 385–99.

M.F.X. Wagner: Proc. ICSMA-15, 2010, pp. 1–8.

J.V. Humbeeck: J. Phys. IV, 1991, vol. 1, pp. C4189–97.

N. Jost: Mater. Sci. Eng. A, 1999, vols. 273-5A, pp. 649–53.

A. Mielczareka, M. Marczyk, and W. Riehemann: Solid State Phenom., 2008, vol. 137, pp. 137–44.

M. Pattabi, K. Ramakrishna, and K.K. Mahesh: Mater. Sci. Eng. A, 2007, vol. 448A, pp. 33–38.

Y Liu, J. Laeng, T.V. Chin, and T.H. Nam: J. Alloys Compd., 2008, vol. 449, pp. 144–47.

H. Matsumoto: J. Alloys Compd., 2003, vol. 350, pp. 213–27.

C. Urbina, S. De la Flor, and F. Ferrando: Mater. Sci. Eng. A, 2009, vol. A501, pp. 197–206.

D. Wurzel: Mater. Sci. Eng. A, 1999, vols. 273-5A, pp. 634–38.

I. Karaman, H.E. Karaca, H.J. Maier, and Z.P. Luo: Metall. Mater. Trans. A 2003, vol. 34A, pp. 2527–39.

D. Treppmann and E. Hornbogen: J. Phys. IV, 1997, vol. 7, pp. 211–20.

D.P. Field: Ultramicroscopy, 1997, vol. 67, pp. 1–9.

M.M. Nowell and S.I. Wright: Ultramicroscopy, 2005, vol. 103, pp. 41–58.

K. Gall and H.J. Maier: Acta Mater., 2002, vol. 50, pp. 4643–57.

B. Verlinden, J. Driver, I. Samajdar, and R.D. Doherty: Thermo-Mechanical Processing of Metallic Materials, R.W. Cahn, ed., Elsevier, Amsterdam, the Netherlands, 2007.

C.M. Wayman: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1787–95.

R.W.K Honeycomb and H.K.D.H. Bhadeshia: Steels: Microstructure and Properties, 3rd ed. Edward Arnold, ed., Butterworths-Heinemann, Oxford, UK, 2006.

K.F. Hane and T.W. Shield: Acta Mater., 2000, vol. 47, pp. 2603–17.

V.D. Hiwarkar, S.K. Sahoo, K.V. Mani Krishna, I. Samajdar, G.K. Dey, D. Srivastav, R. Tewari, S. Banarjee, and R.D. Doherty: Acta Mater., 2009, vol. 57, pp. 5812–21.

S. Miyazaki, K. Otsuka, and C.M. Wayman: Acta Metall., 1989, vol. 37, pp. 1873–84.

K. Madangopal: Acta Mater., 2000, vol. 48, pp. 1325–44.

A.J. Bogers and W.G. Burgers: Acta Metall., 1964, vol. 12, p. 255.

Acknowledgments

Support from the National Facility of Texture and OIM (a DST-IRPHA project) at IIT Bombay is acknowledged. This work was supported by a major grant from UK-India Education Research Initiative (UKIERI) and Rolls-Royce Plc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 5, 2010.

Rights and permissions

About this article

Cite this article

Basu, R., Jain, L., Maji, B.C. et al. Origin of Microstructural Irreversibility in Ni-Ti Based Shape Memory Alloys during Thermal Cycling. Metall Mater Trans A 43, 1277–1287 (2012). https://doi.org/10.1007/s11661-011-0970-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0970-y