Abstract

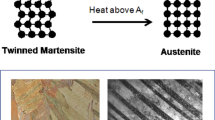

Shape memory behavior in stoichiometric Ni–Hf–Ti shape memory alloys with high Hf was evaluated. Five alloy compositions with a hafnium content from 30 to 50 at.% were arc melted, homogenized, and tested to reveal microstructure and shape memory properties. Transformation temperatures increased linearly with Hf addition, reaching a maximum austenite finish temperature of 1190 °C at 50Hf, measured using differential scanning calorimetry (DSC). The low temperature stable microstructures were composed of a majority B33 orthorhombic phase, with traces of B19′ monoclinic structure below the martensite finish temperature, as revealed by X-ray diffraction (XRD) and Transmission Electron Microscopy (TEM). These microstructures convert to a B2 cubic structure at higher temperature. Macroscopically, specimens were tested isothermally at room temperature, and endured stresses as high as 1 GPa in compression. Strain recovery decreased from nearly 100% recovery in the 30Hf alloy, to nearly 0% at 50Hf alloy, as plasticity mechanisms dominated at high temperatures in the higher Hf alloys. Uniaxial constant-force thermal cycling (UCFTC) experiments revealed limited work output at high temperatures due to creep-dominant mechanisms simultaneously occurring during the phase transformation process.

Similar content being viewed by others

References

Benafan O, Bigelow GS, Garg A, Noebe RD, Gaydosh DJ, Rogers RB (2021) Processing and scalability of NiTiHf high-temperature shape memory alloys. Shape Mem Superelast 7(1):109–165

Yamabe-Mitarai Y (2020) TiPd-and TiPt-based high-temperature shape memory alloys: a review on recent advances. Metals 10(11):1531

Chastaing K, Denquin A, Portier R, Vermaut P (2008) High-temperature shape memory alloys based on the RuNb system. Mater Sci Eng A 481:702–706

Canadinc D, Trehern W, Ma J, Karaman I, Sun F, Chaudhry Z (2019) Ultra-high temperature multi-component shape memory alloys. Scripta Mater 158:83–87

AbuJudom DN, Thoma PE, Kao MY, Angst DR (1992) High transformation temperature shape memory alloy, U.S. Patent No. 5,114,504

Angst DR, Thoma PE, Kao MY (1995) The effect of hafnium content on the transformation temperatures of Ni49Ti51-xHfx. Shape memory alloys. J Phys IV France 05(C8):C8-747-C8-752

Pu ZJ, Tseng HK, Wu KH (1994) Innovative system of high-temperature shape memory alloys, Proc. SPIE 2189, Smart Structures and Materials 1994: Smart Materials, pp. 289–297.

Zhu Y, Pu Z, Li C, Wu K (1994) Stability of NiTi-Pd and NiTi-Hf high temperature shape memory alloys. Florida International Univ, Miami

Wu KH, Pu ZJ, Tseng HK, Biancaniello FS (1994) The Shape Memory Effect of the NiTi-Hf High Temperature Shape Memory Alloy, Proc. The 1st International Conference on Shape Memory and Superelastic Technologies, Pacific Grove, CA, pp. 61–66.

Potapov PL, Shelyakov AV, Gulyaev AA, Svistunov EL, Matveeva NM, Hodgson D (1997) Effect of Hf on the structure of Ni-Ti martensitic alloys. Mater Lett 32(4):247–250

Gu H, Leung K, Chung C (1998) Growth of high-temperature NiTi1–x Hfx shape memory alloy thin films by laser ablation of composite targets. J Vac Sci Technol A 16(6):3420–3422

Kang S-H, Nam T-H (2001) Crystal structure of (TiHf) Ni phase formed in a 20Ti− 50Ni− 30Hf (at.%) alloy. Metals Mater Int 7(5):443–446

Sanjabi S, Cao Y, Barber Z (2005) Multi-target sputter deposition of Ni50Ti50− xHfx shape memory thin films for high temperature microactuator application. Sens Actuators A 121(2):543–548

Muir Wood AJ, Sanjabi S, Fu YQ, Barber ZH, Clyne TW (2008) Nanoindentation of binary and ternary Ni–Ti-based shape memory alloy thin films. Surf Coat Technol 202(13):3115–3120

Tong Y, Liu Y, Miao J (2008) Phase transformation in NiTiHf shape memory alloy thin films. Thin Solid Films 516(16):5393–5396

Rao J, Roberts T, Lawson K, Nicholls J (2010) Nickel titanium and nickel titanium hafnium shape memory alloy thin films. Surf Coat Technol 204(15):2331–2336

Santamarta R, Arróyave R, Pons J, Evirgen A, Karaman I, Karaca H, Noebe R (2013) TEM study of structural and microstructural characteristics of a precipitate phase in Ni-rich Ni–Ti–Hf and Ni–Ti–Zr shape memory alloys. Acta Mater 61(16):6191–6206

Patriarca L, Sehitoglu H (2015) High-temperature superelasticity of Ni50. 6Ti24. 4Hf25. 0 shape memory alloy. Scripta Mater 101:12–15

Patriarca L, Sehitoglu H, Panchenko EY, Chumlyakov Y (2016) High-temperature functional behavior of single crystal Ni51. 2Ti23. 4Hf25. 4 shape memory alloy. Acta Mater 106:333–343

Abuzaid W, Sehitoglu H (2017) Functional fatigue of Ni50. 3Ti25Hf24.7–Heterogeneities and evolution of local transformation strains. Mater Sci Eng A 696:482–492

Sehitoglu H, Wu Y, Patriarca L (2017) Shape memory functionality under multi-cycles in NiTiHf. Scripta Mater 129:11–15

Bucsek AN, Hudish GA, Bigelow GS, Noebe RD, Stebner AP (2016) Composition, compatibility, and the functional performances of ternary NiTiX high-temperature shape memory alloys. Shape Mem Superelast 2(1):62–79

Umale T, Salas D, Tomes B, Arroyave R, Karaman I (2019) The effects of wide range of compositional changes on the martensitic transformation characteristics of NiTiHf shape memory alloys. Scripta Mater 161:78–83

Yeremenko V, Semenova E, Tretyachenko L, Petyukh V (1993) Constitution of the Hf-Ni system up to 50.at% Ni. J Alloys Compds 191(1):117–119

Gupta K (2001) The Hf-Ni-Ti (hafnium-nickel-titanium) system. J Phase Equilibr 22(1):69–72

Cacciamani G, Riani P, Valenza F (2011) Equilibrium between MB2 (M= Ti, Zr, Hf) UHTC and Ni: a thermodynamic database for the B-Hf–Ni–Ti–Zr system. Calphad 35(4):601–619

Nash P, Nash A (1983) The Hf-Ni (hafnium-nickel) system. Bull Alloy Phase Diagr 4(3):250–253

Semenova EL (2001) The solidus surface in the Ti-Ni-Hf system in the Ti-TiNi-HfNi-Hf region. Powder Metall Met Ceram 40(7):414–425

Ross AJ, Gheno T, Ray PK, Kramer MJ, Liu XL, Lindwall G, Zhou B, Shang SL, Gleeson B, Liu ZK (2018) A first-principles based description of the Hf-Ni system supported by high-temperature synchrotron experiments. Thermochim Acta 668:142–151

Liu J, Zhu L, Huang X, Cai G, Jin Z (2017) Investigation of the phase equilibria in Ti-Ni-Hf system using diffusion triples and equilibrated alloys. Calphad 58:160–168

ASTM E3097–17, Standard Test Method for Mechanical Uniaxial Constant Force Thermal Cycling of Shape Memory Alloys, ASTM International, West Conshohocken, PA, 2017, www.astm.org.

ASTM E3098–17, Standard Test Method for Mechanical Uniaxial Pre-strain and Thermal Free Recovery of Shape Memory Alloys, ASTM International, West Conshohocken, PA, 2017, www.astm.org.

Zunger A, Wei S-H, Ferreira L, Bernard JE (1990) Special quasirandom structures. Phys Rev Lett 65(3):353

Van de Walle A, Tiwary P, De Jong M, Olmsted D, Asta M, Dick A, Shin D, Wang Y, Chen L-Q, Liu Z-K (2013) Efficient stochastic generation of special quasirandom structures. Calphad 42:13–18

Kresse G, Hafner J (1993) Ab initio molecular dynamics for liquid metals. Phys Rev B 47(1):558

Kresse G, Hafner J (1994) Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys Rev B 49(20):14251

Kresse G, Furthmüller J (1996) Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci 6(1):15–50

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54(16):11169

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77(18):3865

Blöchl PE (1994) Projector augmented-wave method. Phys Rev B 50(24):17953

Kresse G, Joubert D (1999) From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B 59(3):1758

Wu Z, Lawson JW (2022) Theoretical investigation of phase transitions in the shape memory alloy NiTi. Phys Rev B 106(14):L140102

ASTM F2004–17, Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis, ASTM International, West Conshohocken, PA, 2017, www.astm.org, 2017.

Wolten G (1963) Diffusionless phase transformations in zirconia and hafnia. J Am Ceram Soc 46(9):418–422

Benafan O, Bigelow GS, Young AW (2020) Shape memory materials database tool—a compendium of functional data for shape memory materials. Adv Eng Mater 22(7):1901370

Caltagirone PE, Benafan O (2023) Shape memory materials analysis and research tool (SM2ART): finding data anomalies and trends. Shap Mem Superelasticity 9:558–584

Li K, Zheng W (2023) Thermodynamic modeling of the Ni–Ti–Hf system. Calphad 81:102558

Raj S, Noebe R (2013) Low temperature creep of hot-extruded near-stoichiometric NiTi shape memory alloy part II: effect of thermal cycling. Mater Sci Eng A 581:154–163

Kumar PK, Desai U, Monroe JA, Lagoudas DC, Karaman I, Bigelow G, Noebe RD (2011) Experimental investigation of simultaneous creep, plasticity and transformation of Ti50. 5Pd30Ni19. 5 high temperature shape memory alloy during cyclic actuation. Mater Sci Eng A 530:117–127

Chaugule PS, Benafan O, le Graverend J-B (2021) Phase transformation and viscoplasticity coupling in polycrystalline nickel-titanium-hafnium high-temperature shape memory alloys. Acta Mater 221:117381

Acknowledgements

Funding from the NASA Aeronautics Research Mission Directorate (ARMD) Transformational Tools and Technologies (TTT) project is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Benafan, O., Bigelow, G.S., Garg, A. et al. Ultra-High Temperature Shape Memory Behavior in Ni–Ti–Hf Alloys. Shap. Mem. Superelasticity 10, 55–69 (2024). https://doi.org/10.1007/s40830-024-00473-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-024-00473-1