Abstract

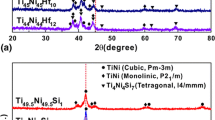

The effect of Si addition on the microstructure and shape recovery of FeMnSiCrNi shape memory alloys has been studied. The microstructural observations revealed that in these alloys the microstructure remains single-phase austenite (γ) up to 6 pct Si and, beyond that, becomes two-phase γ + δ ferrite. The Fe5Ni3Si2 type intermetallic phase starts appearing in the microstructure after 7 pct Si and makes these alloys brittle. Silicon addition does not affect the transformation temperature and mechanical properties of the γ phase until 6 pct, though the amount of shape recovery is observed to increase monotonically. Alloys having more than 6 pct Si show poor recovery due to the formation of δ-ferrite. The shape memory effect (SME) in these alloys is essentially due to the γ to stress-induced ε martensite transformation, and the extent of recovery is proportional to the amount of stress-induced ε martensite. Alloys containing less than 4 pct and more than 6 pct Si exhibit poor recovery due to the formation of stress-induced α′ martensite through γ-ε-α′ transformation and the large volume fraction of δ-ferrite, respectively. Silicon addition decreases the stacking fault energy (SFE) and the shear modulus of these alloys and results in easy nucleation of stress-induced ε martensite; consequently, the amount of shape recovery is enhanced. The amount of athermal ε martensite formed during cooling is also observed to decrease with the increase in Si.

Similar content being viewed by others

References

K. Enami, A. Nagasawa, and S. Nenno: Scripta Metall., 1975, vol. 9, pp. 941–48.

A. Sato, E. Chisima, K. Soma, and T. Mori: Acta Metall., 1982, vol. 30, pp. 1177–83.

M. Murakami, H. Otsuka, H. Suzuki, and S. Matsuda: Trans. ISIJ, 1987, vol. 27, p. B-88.

H. Otsuka, H. Yamada, H. Tanahashi, and T. Maruyama: Mater. Sci. Forum, 1990, vols. 56–58, pp. 655–60.

T.Y. Hsu: J. Mater. Sci. Technol., 1994, vol. 10, pp. 107–10.

A. Ariapour, I. Yakubtsov, and D. Perovic: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1621–28.

H. Otsuka, S. Kajiwara, and T. Ishihara: Mater. Charact., 1994, vol. 32, pp. 229–35.

S. Kajiwara, D. Liu, T. Kikuchi, and N. Shinya: Scripta Mater., 2001, vol. 44, pp. 2809–14.

A. Sato, Y. Yamaji, and T. Mori: Acta Metall., 1986, vol. 34, pp. 287–94.

M. Murakami, H. Otsuka, H. Suzuki, and S. Matsuda: Proc. Int. Conf. on Martensitic Transformations (ICOMAT-86), Nara, Japan, 1986, pp. 985–90.

M. Andersson, R. Stalmans, and J. Agren: Acta Metall., 1998, vol. 46, pp. 3883–91.

A.A. Gulyaev: J. Phys. IV, 1995, vol. 5, pp. 469–74.

X. Tian and Y. Zhang: Mater. Sci. Eng. A, 2009, vol. 516A, pp. 73–77.

K. Tsuzaki, M. Ikegami, Y. Tomota, K. Kurokawa, W. Nakagawara, and T. Maki: Mater. Trans. JIM, 1992, vol. 33, pp. 236–70.

Y. Tamota, M. Piao, T. Hasunuma, and Y. Kimura: Jpn. Inst. Met., 1990, vol. 54, pp. 628–34.

V.G. Gavriljuk, V.V. Bliznuk, B.D. Shanina, and S.P. Kolesnik: Mater. Sci. Eng. A, 2005, vol. 406A, pp. 1–10.

H. Otsuka, H. Yamada, T. Maruyama, H. Tanahashi, S. Matsuda, and M. Murakami: ISIJ Int., 1990, vol. 30, pp. 674–79.

F.B. Pickering: Physical Metallurgy and the Design of Steels, Applied Science Publishers Ltd., London, 1978, p. 226.

E.I. Gladyshevskii, P.I. Kripyakevich, and Y.B. Kuz’ma: J. Str. Chem., 1962, vol. 3, pp. 402–10.

H.M. Rietveld: Acta Cryst., 1967, vol. 22, pp. 151–52.

A. Le Bail, H. Duroy, and J.L. Fourquet: Mater. Res. Bull., 1988, vol. 23, pp. 447–52.

J.H. Yang and C.M. Wayman: Mater. Character., 1992, vol. 28, pp. 23–35.

B.C. Maji, M. Krishnan, and V.V. Rama Rao: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1029–42.

L. Federzoni and G. Guenin: Scripta Metall. Mater., 1994, vol. 31, pp. 25–30.

J.H. Jun, W. Jin, and C.S. Choi: Scripta Metall. Mater., 1995, vol. 33, pp. 1339–44.

J.H. Yang and C.M. Wayman: Metall. Trans. A, 1992, vol. 23A, pp. 1445–54.

B.C. Maji and M. Krishnan: Scripta Mater., 2003, vol. 48, pp. 71–77.

C. Zhao: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2599–2604.

B.E. Warren and B.L. Averbach: J. Appl. Phys., 1950, vol. 21, pp. 595–99.

Schramm and R.P. Reed: Metall. Trans. A, 1975, vol. 6A, pp. 1345–51.

G. Ghosh and G.B. Olson: Acta Mater., 2002, vol. 50, pp. 2655–75.

Acknowledgments

The authors are grateful to Dr. A.K. Suri, Director, Materials Group, BARC, and Dr. G.K. Dey, Head, Materials Science Division, BARC, for their support and encouragement for the work on shape memory alloys. We thank Mr. A. Laik, Dr. C.B. Basak, and Dr. S. Majumdar for the help received in carrying out the EPMA and SEM during this work. We are also grateful to Messrs. V.C. Krishnamohan Nair and S. Yadav for the melting and fabrication of alloys used in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 5, 2010.

Rights and permissions

About this article

Cite this article

Maji, B.C., Krishnan, M., Gouthama et al. Role of Si in Improving the Shape Recovery of FeMnSiCrNi Shape Memory Alloys. Metall Mater Trans A 42, 2153–2165 (2011). https://doi.org/10.1007/s11661-011-0651-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0651-x