Abstract

The microstructure and corresponding tensile properties of both plain and Nb-microalloyed grades of ultrathin cast strip (UCS) low alloy steel produced using the CASTRIP® process were studied. Both as-cast and hot-rolled strip cast steels with various levels of Nb microalloying were manufactured and investigated in this study. Hot rolling had little effect on the yield strength of Nb microalloyed UCS specimens for a given chemical composition, but resulted in a slightly finer microstructure. The effect of Nb microalloying was significant, and this is attributable to the promotion of finer, tougher austenite transformation products such as bainite and acicular ferrite at the expense of large polygonal ferrite grains. A fine dispersion of Nb solute clusters was observed in all Nb-containing steels following hot rolling, and it is suggested that this also contributes to the observed strengthening.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The CASTRIPFootnote 1 process is a revolutionary new twin-roll strip casting method of producing steel sheet directly from the liquid. Using this technique, thin (~1 to 1.5 mm) strip steel can be produced with significantly less energy, time, and floor space, while maintaining higher production levels compared to conventional slab casting techniques.[1–3] Initially, only plain carbon steels were produced using this particular strip casting method, but the production of higher strength grades using microalloyed steels has more recently been established following extensive plant trials and fundamental investigations. This study was undertaken as part of the supporting research for the manufacture of microalloyed ultrathin cast strip (UCS) steels. The effect of microalloying additions such as Nb on steel microstructure was hitherto unknown for this UCS steel. A unique feature of UCS steel is that the solidification process occurs within 200 to 300 ms, compared to conventional slab casting in which several minutes are required for complete solidification. The aim of this study is to provide new information about the microstructure-property relationships in microalloyed grades of these exciting new steels, which are expected to form an entirely new sheet steel product category with the potential to replace both hot-rolled and cold-rolled steel sheet in many applications. To this end, a series of UCS steels produced by the CASTRIP process with varying levels of Nb content were manufactured for study in both as-cast and hot-rolled states.

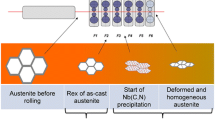

It is most noteworthy that the effects of hot rolling on steel microstructures and mechanical properties were investigated by many researchers, and a very large body of knowledge is available in this area.[4–8] It is generally accepted that hot rolling leads to finer ferrite grains. This is because hot rolling recrystallizes austenite grains, resulting in smaller austenite grains and, subsequently, finer ferrite grains. Furthermore, hot rolling refines ferrite grain size by introducing strain fields within any nonrecrystallized austenite grains, providing extra nucleation sites for ferrite to nucleate and grow intragranularly in addition to along prior austenite grain boundaries. Hot rolling was also found to retard the ferrite grain growth in these steels via mechanical stabilization,[5–8] whereby high density dislocations introduced by rolling act as obstacles to the interface migration of ferrite into austenite. These result in a finer grain structure and, consequently, better strength for the product. In respect to the effect of Nb microalloying on high-strength low-alloy steels, many studies have been carried out.[9–15] An important and widely reported effect in both theoretical and experimental studies is the decrease in the transformation start temperature, thus favoring the formation of low-temperature transformation products such as acicular ferrite and bainite. It also has been demonstrated that Nb precipitates strongly retard austenite recrystallization.[15,16] Furthermore, Nb additions are known to impart improved strength to these steels through the formation of nanoscale NbC or Nb(NC) precipitates, which retard the movement of dislocations within the grains during deformation.[9–14] In this research, we provide the first comprehensive evaluation of the effects of hot rolling and Nb microalloying on the detailed microstructure-property relationships in UCS steels.

2 Materials and methods

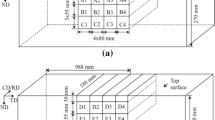

As-cast and hot-rolled UCS specimens with various Nb contents were produced using the CASTRIP process. Using this unique technique, liquid steel is passed through twin-casting rolls and solidifies within milliseconds to produce continuous as-cast steel sheet of ~1.8-mm thickness. The as-cast steel sheet is then immediately hot rolled once to achieve ~1.3-mm thickness, water spray cooled, and finally coiled as the hot-rolled commercial product.[2,3] The chemical compositions and processing parameters for the materials studied in this article are listed in Table I.

Engineering stress-strain curves were obtained using standard tensile tests on dog-bone shaped coupons with a strain rate of 0.008 s–1, and the yield strength for each specimen was determined by the stress corresponding to 0.2 pct strain. Metallographic specimens for light optical microscopy, transmission electron microscopy (TEM), and atom probe tomography (APT) were prepared from the materials in Table I using standard techniques.[17,18] An OlympusFootnote 2 BX61 metallurgical microscope was used for light microscopy, and both a 120 keV PHILIPSFootnote 3 CM12 and a 300 keV JEOLFootnote 4 3000F TEM were used for electron microscopy. APT experiments provide chemical and spatial information for the individual atoms in the material with near-atomic resolution[19,20] and were used to study the distribution of the Nb atoms in detail. They were conducted using an Imago LEAPFootnote 5 microscope[19] operating at 20 K (–253 °C) with a pulse fraction of 20 pct, a flight path of 90 mm, and a pulse repetition rate of 200 kHz. APT data were reconstructed using the method described by Gault et al.[20]

3 Results

The yield strength of each specimen is plotted in Figure 1, and the standard deviations were found to be within 10 MPa. Slightly different steel compositions were evaluated for the as-cast vs hot-rolled Nb-free steels, as indicated in Table I. Based on these results, hot rolling seems to have a minor effect on yield strength for both Nb-free and Nb microalloyed steels. The strengthening arising from microalloying with Nb was significant, leading to a plateau yield strength increase of 20 to 30 pct relative to the Nb-free hot-rolled specimen at a level of about 0.04 wt pct Nb. Hot rolling appeared to have had only a minor effect on yield strength for the Nb bearing specimens.

Figures 2 through 4 summarize the results of light optical microscopy. All the optical images were taken from cross sections along the hot rolling direction. Optical images from transverse sections and cross sections perpendicular to the hot rolling direction were also taken with no noticeable microstructure differences observed. The microstructure through the thickness of each specimen was also studied, and no substantial differences were noticed. The as-cast and hot-rolled microstructures for the Nb-free and the 0.084 wt pct Nb specimens are compared in Figures 2 and 3 at different magnifications. The images in Figure 2 show an overview of the structure, which is quite heterogeneous in some cases. The images in Figure 3 are taken at higher magnification from the areas that have the finest structure in the same specimens. The microstructure of Nb-free as-cast steel (Figure 2(a)) consisted mostly of acicular and bainitic ferrite, together with a minor amount of polygonal ferrite decorating the prior austenite grain boundaries. Figure 2(b) reveals that some prior austenite grains possess the bainite/acicular ferrite microstructure, while many others have transformed entirely to polygonal ferrite. The polygonal ferrite observed in Nb-free hot-rolled steel is finer than the corresponding as-cast one. However, in the 0.084 wt pct Nb-containing steel in the as-cast condition (Figure 2(c)), bainite and acicular ferrite dominate the microstructure and there was no polygonal ferrite observed. Figure 2(d) reveals that hot rolling of the Nb-containing steel refines the bainite and acicular ferrite. An examination of the detailed nature of the acicular ferrite in the as-cast specimens (Figures 3(a) and (c)) revealed a conventional lath structure that appeared to grow radially from the nucleation site within the prior austenite grains, resulting in an interlocking morphology. In contrast, most of the acicular ferrite observed in the hot-rolled specimens (Figures 3(b) and (d)) also exhibited interlocking acicular ferrite morphology but possessed shorter laths. Figure 4 is also a series of light optical micrographs that compare the microstructures of hot-rolled Nb-containing UCS steels. When as little as 0.026 wt pct Nb was added into the steel, the formation of classical polygonal ferrite was suppressed and replaced by bainite and acicular ferrite. This microstructure was even finer in the 0.041 wt pct Nb microalloyed steel, while further Nb addition did not seem to change the microstructure substantially.

Cross-sectional optical microstructure of (a) Nb-free as-cast, (b) Nb-free hot-rolled, (c) 0.084 wt pct Nb as-cast, and (d) 0.084 wt pct Nb hot-rolled specimens along the rolling direction. The prior austenite grain boundaries are indicated by dashed lines, and regions 1 and 2 show typical polygonal ferrite (polygon-shape ferrite) and bainite/acicular ferrite (lathlike ferrite), respectively

Cross-sectional optical micrographs showing the effect of Nb additions in hot-rolled steels: (a) 0.026 wt pct Nb, (b) 0.041 wt pct Nb, (c) 0.065 wt pct Nb, and (d) 0.084 wt pct Nb additions along the rolling direction. The prior austenite grain boundaries, elongated along the rolling direction, are indicated by dashed lines in (d)

Since ferrite laths in bainite generally exhibit very small misorientation, it is difficult to etch out the grain boundary using 2 pct nital, and TEM was used to show this microstructure in greater detail. Representative bright-field (BF) TEM images from the 0.084 wt pct Nb-containing steel after hot rolling are provided in Figure 5 and reveal both the complexity of the bainitic ferrite and the acicular ferrite microstructures. Similar structures were observed for the 0.026, 0.041, and 0.065 wt pct Nb hot-rolled steels and 0.084 wt pct as-cast steel. TEM experiments did not reveal any evidence for the presence of dispersions of second-phase precipitate particles such as Nb(C, N), despite careful tilting experiments and the application of various modalities such as selected area diffraction, high resolution imaging, and dark-field imaging. This was the case for all concentrations of Nb, and Figure 5(c) is a representative BF image for the 0.084 wt pct Nb-containing steel after hot rolling.

Atom probe microanalysis was applied to investigate the role of Nb given the absence of precipitation, and the results are summarized in Figure 6 from the 0.041wt pct Nb-containing steel after hot rolling. Figure 6(a) provides the mass spectra from the analysis and shows the various species that field evaporated and how they were identified. Figure 6(b) is an atom map with Fe atoms shown in blue and the molecular species NbN, in which Nb and N ions in the cluster were field evaporated together to give a single signal, labeled as red. It is very clear that the Nb atoms are not uniformly distributed and that, in fact, there are extremely fine atomic clusters of Nb and N atoms, which are beyond the resolution of TEM.

4 Discussion

4.1 Effect of Hot Rolling on Microstructure and Yield Strength

Previous work done on plain carbon CASTRIP steels showed that hot rolling lowered yield strength.[2,3,21] However, in this study, hot rolling was observed to have little effect on the tensile mechanical properties of both the Nb-free and Nb-containing CASTRIP steels, though there are obvious microstructural effects and these are slightly different depending on whether the steel is microalloyed. All hot rolling was carried out at 1152 K to 1185 K (879 °C to 912 °C) (Table I), which is in the austenite phase field. In the Nb-free steels, the as-cast material contains roughly equal amounts of polygonal and bainite/acicular ferrite, as shown in Figure 2(a), whereas the hot-rolled material clearly has more polygonal ferrite with only about 15 pct acicular ferrite left in the microstructure, as shown in Figure 2(b). This change probably reflects the fact that hot rolling promotes recrystallization and grain refinement of austenite,[3,21] and the resulting smaller austenite grains will discourage intragranular acicular ferrite nucleation.[22] Some small austenite grains, therefore, are completely dominated by polygonal ferrite, and the volume fraction of acicular ferrite decreases with increasing degree of hot rolling.[21] However, a small amount of acicular ferrite that results from larger austenite grains was still present in the microstructure. This indicates that a small proportion of austenite grains were not recrystallized during hot rolling. This is probably because steel sheets underwent only one-pass hot rolling in which the microstructure is not homogenized. Since a large proportion of hard acicular ferrite is replaced by soft polygonal ferrite in the Nb-free as-cast steel, a drop in the yield strength of the Nb-free hot-rolled steels might be expected. However, no obvious difference in mechanical properties between Nb-free as-cast and hot-rolled steels was noticed in this study. This discrepancy is probably due to the higher Mn content and lower coiling temperature, thus higher continuous cooling rate in the Nb-free hot-rolled steels. For coiling, the temperature drop from the hot-rolling temperature for the 0.065 wt pct Nb steel is 684 K (411 °C), compared to ~603 K (330 °C) for most of the other steels. The higher Mn content has a strengthening effect, and a higher cooling rate promotes ferrite nucleation but retards ferrite grain growth, which refines the overall microstructure from the austenite-to-ferrite transformation.

In the Nb-containing steels, the as-cast specimen microstructure comprises bainite that nucleates at prior austenite grain boundaries together with acicular ferrite throughout the intragranular region of the prior austenite grains. After hot rolling, the microstructure became more chaotic, with bainite islands and some acicular ferrite throughout the microstructure. The addition of Nb suppresses the recrystallization of austenite so that large austenite grains are deformed but the general size is retained.[3,23] Hot rolling also creates additional nucleation sites such as dislocation bands for ferrite laths to grow within the prior austenite grains. The further growth of bainite and acicular ferrite is limited by the neighboring ferrite grains nucleated on other defects within the same prior austenite grain, which results in a refined microstructure. This observation agrees with similar studies carried out on other steels with structures dominated by bainite.[6,7] The present results demonstrate that both Nb-free and Nb-containing steels contain acicular ferrite in as-cast condition and that this ferrite is made up of long, thin laths. After hot rolling, the ferrite laths were noticeably shorter. This is believed to result from the fact that hot-rolled austenite grains contain more defects that can provide nucleation sites. It is understood that this decomposition of austenite occurs more rapidly in hot-rolled steels, generating a greater number of “sympathetic” nucleation points. These nucleation points encourage the formation of acicular ferrite and subsequent growth impingement, thereby resulting in a more refined microstructure.

4.2 Effect of Microalloying with Nb

For both the as-cast and hot-rolled conditions of the UCS steels produced by the CASTRIP process, the addition of Nb increases the yield strength substantially to 0.041 wt pct Nb and then reaches a plateau with further Nb additions. This agrees well with the microstructural evolution apparent with Nb additions in Figures 2 through 4, where a higher proportion of finer phases such as acicular ferrite and bainite are observed with increasing Nb concentration. Since bainite and acicular ferrite have smaller grain sizes than polygonal ferrite, it is proposed that the Nb-containing steels are strengthened by grain refinement.

It was reported that Nb decreases the transformation start temperature of austenite to ferrite, enhancing the formation of lower temperature products such as ferrite and bainite.[24–27] It is believed that Nb, both in solution and segregated to austenite grain boundaries, retards recovery and recrystallization of deformed austenite, where defects stored in the austenite provide additional intragranular nucleation sites for ferritic phases,[27] promoting the formation of lower temperature ferrite products. Nb segregation at austenite grain boundaries also reduces the interfacial energy and, consequently, makes those grain boundaries less effective nucleation sites for polygonal ferrite;[28] thus, a transformation to bainite/acicular ferrite is favored. Furthermore, because the growth of bainite/acicular ferrite is displacive while the nucleation and growth of polygonal ferrite are diffusive, the dislocation density in bainite/acicular ferrite is higher than that in polygonal ferrite,[22] which provides additional strength in the Nb-microalloyed steels.

The fact that no Nb-rich carbo-nitride precipitation was observed via TEM suggests that there was no contribution to the strengthening from precipitation hardening.[9–14] It is conjectured that the absence of Nb(C,N) precipitation in the as-cast and hot-rolled steels is due to the fast cooling rates (60 to 80 K/s upon water cooling) applied in the CASTRIP process. Consequently, the Nb atoms are essentially retained in a supersaturated ferritic solid solution.

It was further observed that the Nb atoms are contained within the ferrite in a distinctly nonrandom configuration and seem clustered together with N atoms. These clusters may be expected to contribute a cluster strengthening effect[29] along with the more conventional forms of solid solution strengthening from individual Nb solute atoms[27,30,31] throughout the ferrite.

5 Conclusions

-

1.

Nb microalloying additions increased the yield strength of UCS steels produced by the CASTRIP process mainly by favoring the formation of bainite and acicular ferrite at the expense of the relatively softer and coarse polygonal ferrite as the products of the austenite transformation. Whereas careful TEM experiments failed to reveal any evidence of precipitation, APT confirmed the presence of Nb-N clusters, and these could also be expected to contribute to the overall strengthening of Nb-containing UCS steels.

-

2.

In the Nb-free steel, hot rolling refined austenite grains via austenite recrystallization; thus, intragranular acicular ferrite formation was suppressed. In the Nb-containing steel, hot rolling provided additional nucleation sites for bainite and acicular ferrite, resulting in a more chaotic structure. Bainite and acicular ferrite were the dominant microstructure in both steels, and no substantial differences in yield strength were observed between the as-cast and corresponding hot-rolled steels.

Notes

CASTRIP is a registered trademark of Castrip LLC, Charlotte, NC.

Olympus is a trademark of Olympus Inc, Center Valley, PA.

PHILIPS is a trademark of FEI Company, Hillsboro, OR.

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

LEAP is a trademark of CAMECA, Gennevilliers, France.

References

F.A. Burgmann, Y. Xie, J.M. Cairney, S.P. Ringer, C.R. Killmore, F.J. Barbaro, and J.G. Williams: Mater. Forum, 2008, vol. 32, pp. 9–12.

C.R. Killmore, H. Creely, A. Phillips, H.R. Kaul, P.C. Campbell, M. Schueren, J.G. Williams, and W.N. Blejde: Development of Ultra-Thin Cast Strip Products by the CASTRIP Process, AISTech, Indianapolis, IN, 2007.

C.R. Killmore, H.R. Kaul, J.R. Burg, K.R. Carpenter, J.G. Williams, D.G. Edelman, P.C. Campbell, and W.N. Blejde: 3rd Int. Conf. on ThermoMechanical Processing of Steels, AIM, Padova, Italy, 2008.

A. Bakkaloglu: Mater. Lett., 2002, vol. 56, pp. 263–72.

C.S. Chiou, J.R. Yang, and C.Y. Huang: Mater. Chem. Phys., 2001, vol. 69, pp. 113–24.

R.H. Larn and J.R. Yang: Mater. Sci. Eng. A, 1999, vol. 264, pp. 139–50.

R.H. Larn and J.R. Yang: Mater. Sci. Eng. A, 2000, vol. 278, pp. 278–91.

C.H. Lee, H.K.D.H. Bhadeshia, and H.C. Lee: Mater. Sci. Eng. A, 2003, vol. 360, pp. 249–57.

R.D.K. Misra, H. Nathani, J. Hartmann, and F. Siciliano: Mater. Sci. Eng. A, 2005, vol. 394, pp. 339–52.

C.P. Reip, S. Shanmugam, and R.D.K. Misra: Mater. Sci. Eng. A, 2006, vol. 424, pp. 307–17.

S. Shanmugam, R.D.K. Misra, J. Hartmann, and S.G. Jansto: Mater. Sci. Eng. A, 2006, vol. 441, pp. 215–29.

S. Shanmugam, R.D.K. Misra, T. Mannering, D. Panda, and S.G. Jansto: Mater. Sci. Eng. A, 2006, vol. 437, pp. 436–45.

S. Shanmugam, N.K. Ramisetti, R.D.K. Misra, J. Hartmann, and S.G. Jansto: Mater. Sci. Eng. A, 2008, vol. 478, pp. 26–37.

S. Shanmugam, N.K. Ramisetti, R.D.K. Misra, T. Mannering, D. Panda, and S.G. Jansto: Mater. Sci. Eng. A, 2007, vols. 460–461, pp. 335–43.

J. Strid: Ph.D. Thesis, University of Technology, Luleå, 1984, pp. 5–14.

A.J. DeArdo, J.M. Gray, and L. Meyer: Niobium, TMS-AIME, Warrendale, PA, 1981.

M.K. Miller, A. Cerezo, M.G. Hetherington, and G.D. Smith: Atom Probe Field Ion Microscopy, Oxford Science Publications, Oxford, United Kingdom, 1996, pp. 476–83.

D.B. Williams and B.C. Carter: Transmission Electron Microscopy, Springer, New York, NY, 1996, pp. 9–10.

B. Gault, M.P. Moody, D.W. Saxey, J.M. Cairney, Z. Liu, R.K. Zheng, R.K.W. Marceau, P.V. Liddicoat, L.T. Stephenson, and S.P. Ringer: Frontiers in Materials Research, Springer, Berlin, 2008, vol. 10, pp. 187–216.

B. Gault, M.P. Moody, F. de Geuser, G. Tsafnat, A. La Fontaine, L.T. Stephenson, D. Haley, and S.P. Ringer: J. Appl. Phys., 2009, vol. 105, pp. 0349130–39.

F.J. Barbaro, P. Krauklis, and K.E. Easterling: Mater. Sci. Technol., 1989, vol. 5, pp. 1057–68.

H.K.D.H. Bhadeshia and R.W.K. Honeycombe: Acicular Ferrite, Butterworh-Heinemann, Oxford, United Kingdom, 2006.

Z.-H. Zhang, Y.-N. Liu, X.-K. Liang, and Y. She: Mater. Sci. Eng. A, 2008, vol. 474, pp. 254–60.

T.M. Hoogendoorn and M.J. Spanraft: Proc. Conf. on Microalloying, Union Carbide Corporation, New York, 1977, vol. 75, pp. 75–85.

J. Strid and K.E. Easterling: Acta Metall., 1985, vol. 33, pp. 2057–74.

Y.-W. Wang, F. Chun, F.-Y. Xu, B.-Z. Bai, and H.-S. Fang: J. Iron Steel Res. Int., 2010, vol. 17, pp. 49–53.

Q. Yu, Z. Wang, X. Liu, and G. GWang: Mater. Sci. Eng. A, 2004, vol. 379, pp. 384–90.

M. Enomoto, N. Nojiri, and Y. Sato: Mater. Trans., JIM, 1994, vol. 35, pp. 859–67.

S.P. Ringer: Mater. Sci. Forum, 2006, vols. 519–521, pp. 25–34.

S.P. Ringer, S.K. Caraher, and I.J. Polmear: Scripta Mater., 1998, vol. 39, pp. 1559–67.

S.P. Ringer, K. Hono, T. Sakurai, and I.J. Polmear: Scripta Mater., 1997, vol. 36, pp. 517–21.

Acknowledgments

The authors are grateful for partial funding support from the Australian Research Council and BlueScope Steel Pty. Ltd. (BSL). Messrs. Kristin Carpenter and Harold Kaul (BSL) are thanked for their scientific and technical input and informative discussions. The authors are also grateful for the scientific and technical input and support from the Australian Microscopy and Microanalysis Research Facility (AMMRF) at the University of Sydney, particularly from Drs. David Mitchell and Flame Burgmann and Messrs. Peter Felfer, Adam Sikorski, and Alex La Fontaine.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 28, 2010.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Xie, K.Y., Yao, L., Zhu, C. et al. Effect of Nb Microalloying and Hot Rolling on Microstructure and Properties of Ultrathin Cast Strip Steels Produced by the CASTRIP® Process. Metall Mater Trans A 42, 2199–2206 (2011). https://doi.org/10.1007/s11661-011-0622-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0622-2