Abstract

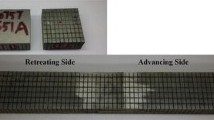

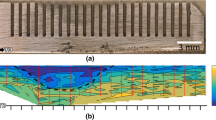

The dislocation density and subgrain size were determined in the base material and friction-stir welds of 6061-T6 aluminum alloy. High-resolution X-ray diffraction measurement was performed in the base material. The result of the line profile analysis of the X-ray diffraction peak shows that the dislocation density is about 4.5 × 1014 m−2 and the subgrain size is about 200 nm. Meanwhile, neutron diffraction measurements have been performed to observe the diffraction peaks during friction-stir welding (FSW). The deep penetration capability of the neutron enables us to measure the peaks from the midplane of the Al plate underneath the tool shoulder of the friction-stir welds. The peak broadening analysis result using the Williamson–Hall method shows the dislocation density of about 3.2 × 1015 m−2 and subgrain size of about 160 nm. The significant increase of the dislocation density is likely due to the severe plastic deformation during FSW. This study provides an insight into understanding the transient behavior of the microstructure under severe thermomechanical deformation.

Similar content being viewed by others

References

Y. Wang, M. Chen, F. Zhou, and E. Ma: Nature, 2002, vol. 419, pp. 912–15.

R. Valiev: Nat. Mater., 2004, vol. 3, pp. 511–16.

M.A. Krivoglaz: Theory of X-ray and Thermal Neutron Scattering by Real Crystals, Plenum Press, New York, NY, 1996.

B.D. Cullity and S.R. Stock: Elements of X-ray Diffraction, Prentice Hall, Upper Saddle River, NJ, 2001.

M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, R.A. Spurling, and W.H. Bingle: Mater. Trans. A, 1998, vol. 29, pp. 1955–64.

R.S. Mishra and Z.Y. MA: Mater. Sci. Eng. R, 2005, vol. 50, pp. 1–78.

L.E. Murr, G. Liu, and J.C. McClure: J. Mater. Sci., 1998, vol. 33, pp. 1243–51.

K.V. Jata and S.L. Semiatin: Scripta Mater., 2000, vol. 43, pp. 743–49.

J.Q. Su, T.W. Nelson, R. Mishra, and M. Mahoney: Acta Mater., 2003, vol. 53, pp. 713–29.

P.B. Prangnell and C.P. Heason: Acta Mater., 2005, vol. 53, pp. 3179–92.

W. Woo, H. Choo, D.W. Brown, and Z. Feng: Metall. Mater. Trans. A, 2007, vol. 38, pp. 69–76.

A. Simar, Y. Bréchet, B. de Meester, A. Denquin, and T. Pardoen: Acta Mater., 2007, vol. 55, pp. 6133–43.

W. Woo, Z. Feng, X-L. Wang, K. An, H. Choo, C.R. Hubbard, and S.A. David: Appl. Phys. Lett., 2006, vol. 88, p. 248623.

W. Woo, Z. Feng, X.-L. Wang, D.W. Brown, B. Clausen, K. An, H. Choo, C.R. Hubbard, and S.A. David: Sci. Technol. Weld. Join., 2007, vol. 12, pp. 298–303.

W. Woo, Z. Feng, X.-L. Wang, K. An, W.B. Bailey, S.A. David, C.R. Hubbard, and H. Choo: Residual Stresses VII, 2006, vols. 524–525, pp. 387–92.

B.E. Warren and B.L. Averbach: J. Appl. Phys., 1952, vol. 23, p. 497.

G.K. Williamson and W.H. Hall: Acta Metall., 1953, vol. 1, pp. 22–31.

T. Ungár and A. Borbély: Appl. Phys. Lett., 1996, vol. 69, pp. 3173–75.

T. Ungár, I. Dragomir, Á. Révész, and A. Borbély: J. Appl. Cryst., 1999, vol. 32, pp. 992–1002.

G. Ribárik, T. Ungár, and J. Gubicza: J. Appl. Cryst., 2001, vol. 34, pp. 669–76.

T. Ungár, J. Gubicza, G. Ribárik, and A. Borbély: J. Appl. Cryst., 2001, vol. 34, pp. 298–310.

W. Woo, L. Balogh, T. Ungár, H. Choo, and Z. Feng: Mater. Sci. Eng. A, 2008, vol. 498, pp. 308–13.

M.A.M. Bourke, D.C. Dunand, and E. Ustundag: Appl. Phys. A, 2002, vol. 74, pp. S1707-S1709.

A.C. Larson and R.B. Von Dreele: Report No. LAUR 86-748, Los Alamos National Laboratory, Los Alamos, NM, 2004.

M.T. Hutchings, P.J. Withers, T.M. Holden, and T. Lorentzen: Introduction to the Characterization of Residual Stress by Neutron Diffraction, Taylor and Francis, Boca Raton, FL, 2005.

B. Clausen, T. Lorentzen, and T. Leffers: Acta Mater., 1998, vol. 46, pp. 3087–98.

J. Gubicza, N.Q. Chinh, Z. Horita, and T.G. Langdon: Mater. Sci. Eng. A, 2004, vol. 387, pp. 55–59.

Acknowledgments

This research is sponsored by the Laboratory Directed Research and Development programme of Oak Ridge National Laboratory, managed by UT–Battelle, LLC for the United States Department of Energy under Contract No. DE-AC05-00OR22725. Research at the Oak Ridge National Laboratory SHaRE User Center was supported by the Division of Materials Sciences and Engineering, Office of Basic Energy Sciences, United States Department of Energy, under Contract No. DE-AC05-00OR22725 with UT–Battelle, LLC. One of the authors (WW) is supported by the Nuclear Research and Development Program, Korea Science and Engineering Foundation, funded by the Korean government. TU is grateful to the Hungarian National Science Foundation OTKA Nos. 71594 and 67692. The authors also thank L. Balogh, T.A. Sisneros, and D.W. Brown for their help.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given in the symposium “Neutron and X-Ray Studies of Advanced Materials,” which occurred February 15–19, 2009, during the TMS Annual Meeting in San Francisco, CA, under the auspices of TMS, TMS Structural Materials Division, TMS/ASM Mechanical Behavior of Materials Committee, TMS: Advanced Characterization, Testing, and Simulation Committee, and TMS: Titanium Committee.

Rights and permissions

About this article

Cite this article

Woo, W., Ungár, T., Feng, Z. et al. X-Ray and Neutron Diffraction Measurements of Dislocation Density and Subgrain Size in a Friction-Stir-Welded Aluminum Alloy. Metall Mater Trans A 41, 1210–1216 (2010). https://doi.org/10.1007/s11661-009-9963-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9963-5