Abstract

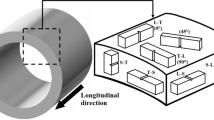

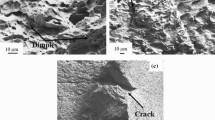

A separation phenomenon occurring during the Charpy impact test of API X80 pipeline steels was investigated in the present study. A detailed microstructural analysis of fractured impact specimens showed that the band structure of bainite elongated along the rolling direction worked as prior initiation sites for separations, and that the number and length of the separations increased with the increasing volume fraction of bainite. In the steels having high work hardenability, tearing-shaped separations were found because the hammer-impacted region was seriously hardened during the impact test, which led to the reduction in the impact toughness. As the test temperature decreased, the tendency toward separations increased, but separations were not found when the cleavage fracture prevailed at very low temperatures. These findings suggested that the formation of bainite and secondary phases should be minimized for preventing or minimizing separations, because separations deteriorated the low-temperature impact toughness.

Similar content being viewed by others

References

M.K. Gräf, H.G. Hillenbrand, C.J. Heckmann, and K.A. Niederhoff: Proc. 13th Int. Offshore and Polar Engineering Conf., R. Ayer, I. Langen, R.H. Knapp, and J.S. Chung, eds., Honolulu, HI, 2003, vol. 4, pp. 97–104.

R. Deny: Pipeline Technology, Elsevier, Amsterdam, The Netherlands, 2000, vol. I, pp. 1–116.

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi: Thermomechanical Processing of High-Strength Low-Alloy Steels, Butterworth & Co., Ltd., London, 1988, pp. 80–100.

I.D. Choi, D.M. Bruce, D.K. Matlock, and J.G.. Speer: Met. Mater. Int., 2008, vol. 14, pp. 139–47.

D.W. Suh, C.S. Oh, and S.J. Kim: Met. Mater. Int., 2008, vol. 14, pp. 175–83.

F.T. Han, B.C. Hwang, D.W. Suh, Z.C. Wang, D.L. Lee, and S.J. Kim: Met. Mater. Int., 2008, vol. 14, pp. 667–73.

M. Diaz-Fuentes, A. Iza-Mendia, and I. Gutierrez: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2505–16.

“ASTM E8m-08 Standard Test Methods for Tension Testing of Metallic Materials,” Annual Book of ASTM Standards, ASTM, West Conshohocken, PA, 2008, vol. 03.01, pp. 1–50.

“ASTM E23-07ae1 Standard Test Method for Notched Bar Impact Testing of Metallic Materials,” Annual Book of ASTM Standards, ASTM, West Conshohocken, PA, 2007, vol. 03.01, pp. 1–27.

W. Oldfield: ASTM Standardization News, 1975, Nov., pp. 24–29.

C. Jing, D.W. Suh, C.S. Oh, Z.C. Wang, and S.J. Kim: Met. Mater. Int., 2007, vol. 13, pp. 13–20.

T. Araki: Atlas for Bainitic Microstructures, ISIJ, Tokyo, 1992, pp. 1–165.

G. Krauss and S.W. Thompson: ISIJ, 1995, vol. 35, pp. 937–45.

G. Baldi and G. Buzzichell: Met. Sci., 1978, vol. 12, pp. 459–72.

B. Hwang, Y.G. Kim, S. Lee, N.J. Kim, and J.Y. Yoo: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 371–87.

D.S. Dabkowski, D.J. Konkol, and M.F. Baldi: Met. Eng. Q., 1976, vol. 16, pp. 22–32.

D.N. Hawkins: Met. Technol., 1976, vol. 3, pp. 417–21.

B.L. Bramfitt and A.R. Marder: Toughness Characterization and Specifications for HSLA and Structural Steels, AIME, New York, 1977, pp. 236–56.

S. Matsuda, Y. Kawashima, S. Sckiguchi, and M. Okamoto: Tetsu-to-Hagané, 1982, vol. 68, pp. 435–43.

M. Iino, H. Mimura, and N. Nomura: Trans. ISIJ, 1977, vol. 17, pp. 450–58.

J.F. Knott: Fundamentals of Fracture Mechanics, John Wiley & Sons, New York, NY, 1973, pp. 114–49.

J.W. Park, J.S. Kim, and I.G. Moon: J. Kor. Inst. Met. Mater., 1984, vol. 22, pp. 5–15.

Acknowledgments

This work was supported by the National Research Laboratory Program (Grant No. ROA-2004-000-10361-0(2008)) funded by the Korea Science and Engineering Foundation (KOSEF) and by POSCO under Contract No. 2008Y220.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 10, 2008.

Rights and permissions

About this article

Cite this article

Shin, S.Y., Hong, S., Bae, JH. et al. Separation Phenomenon Occurring during the Charpy Impact Test of API X80 Pipeline Steels. Metall Mater Trans A 40, 2333–2349 (2009). https://doi.org/10.1007/s11661-009-9943-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9943-9