Abstract

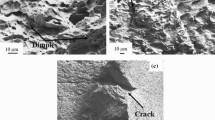

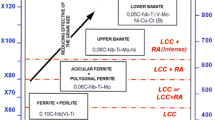

The effects of microstructure on inverse fracture occurring in the hammer-impacted region were analyzed after conducting a drop-weight tear test (DWTT) on high-toughness pipeline steels. Three kinds of steels were fabricated by varying the alloying elements, and their microstructures were varied by the rolling conditions. The pressed-notch (PN) or chevron-notch (CN) DWTT and Charpy V-notch (CVN) impact tests were conducted on the rolled steel specimens, and the results were discussed in comparison with the data obtained from CVN tests of prestrained specimens. In the hammer-impacted region of the DWTT specimens, abnormal inverse fracture having a cleavage fracture mode appeared, and the inverse fracture area correlated well with the upper-shelf energy (USE) obtained from the CVN test and with the grain size. The steel specimens having a higher USE or having coarse polygonal ferrite tended to have a larger inverse fracture area than those having a lower USE or having fine acicular ferrite. This was because steels having a higher impact absorption energy required higher energy for fracture initiation and propagation during the DWTT. These results were confirmed by the CVN data of prestrained steel specimens.

Similar content being viewed by others

References

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi: Thermomechanical Processing of High-Strength Low-Alloy Steels, Butterworth & Co., Ltd, London, 1988.

R. Denys: Pipeline Technology, Proc. 3rd Int. Pipeline Technology Conf., Elsevier, Brugge, Belgium, 2000, vol. I & II.

J.R. Ellwood: Proc. 2000 Int. Pipeline Conf., ASME, Calgary, AB, Canada, 2000.

X.W. Zhao, J.H. Luo, M. Zheng, M.X. Lu, and H.L. Li: Met. Mater. Int., 2002, vol. 8, pp. 479–85.

J.S. Chung and S. Prinsenberg: Proc. 13th Int. Offshore and Polar Engineering Conf. and The ISOPE Symp. on High-Performance Materials in Offshore Industry (HMOI), Honolulu, HI, 2003.

N. Iwasaki, T. Yamaguchi, and T. Taira: Mech. Work Steel Process, 1975, vol. 13, pp. 294–314.

H. Kashimura, M. Ogasawara, and H. Mimura: Metal Prog., 1976, Nov., pp. 58–62.

N. Nozaki, K. Bessyo, Y. Sumitomo, I. Takeuchi, and A. Yamashita: Sumitomo Search, 1981, vol. 26, pp. 76–90.

K. Seifert: Mater. Testing, 1984, vol. 26, pp. 277–80.

L. Pussegoda, L. Malik, A. Dinovitzer, B.A. Graville, and A.B. Rothwell: in Proc. 2000 Int. Pipeline Conf., J.R. Ellwood, ASME, New York, NY, 2000, vol. 1, pp. 239–45.

G. Mannucci and D. Harris: “Fracture Properties of API X100 Gas Pipeline Steels,” Final Report, European Commission, Brussels, Belgium, 2002.

B. Hwang, S. Lee, Y.M. Kim, N.J. Kim, J.Y. Yoo, and C.S. Woo: Mater. Sci. Eng. A, 2003, vol. A368, pp. 18–27.

S. Lee, B. Hwang, Y.M. Kim, N.J. Kim, and J.Y. Yoo: Proc. 17th Conf. on Mechanical Behaviors of Materials, J.H. Hong and Y.S. Kim, eds., Pohang, Korea, 2003, pp. 40–49.

B. Hwang, Y.M. Kim, S. Lee, N.J. Kim, and S.S. Ahn: Metall. Mater. Trans. A, in press.

API Recommended Practice 5L3, API, Washington, D.C., 1996.

E. Heier: “Drop Weight Tear Testing of High Toughness Pipeline Material,” Technical Report, Det Norske Veritas, Norway, 2003.

G.M. McClure, A.R. Duffy, and R.J. Eiber: J. Eng. Industry, 1965, vol. 4, pp. 265–78.

J.Y. Koo, M.J. Luton, N.V. Bangaru, R.A. Petkovic, D.P. Fairchild, C.W. Petersen, H. Asahi, T. Hara, Y. Terada, M. Sugiyama, H. Tamehiro, Y. Komizo, S. Okaguchi, M. Hamada, A. Yamamoto, and I. Takeuchi: Proc. 13th Int. Offshore and Polar Engineering Conf., J.S. Chung and S. Prinsenberg, eds., Honolulu, HI, 2003, pp. 10–18.

A.K. De, J.G. Speer, and D.K. Matlock: Adv. Mater. Process, 2003, vol. 161, pp. 27–30.

ASTM Standard E23-02, ASTM, Philadelphia, PA, 2002.

W. Oldfield: ASTM Standardizations News, 1975, pp. 24–29.

J.H. Hollomon and J.D. Lubahn: Phys. Rev., 1946, vol. 70, p. 775

S.K. Kim: Ph.D. Dissertation, POSTECH, Pohang, Korea, 2002.

H.W. Swift: Met. Ind., 1940, vol. 56, pp. 127–30

Atlas for Bainitic Microstructures, ISIJ, Tokyo, 1992, vol. 1.

T. Hayashi, F. Kawabata, and K. Amano: Conf. Proc. from Materials Solution ’97 on Accelerated Cooling/Direct Quenching of Steels, R. Asfahani, ed., ASM INTERNATIONAL, Materials Park, OH, 1997, pp. 93–99.

G. Krauss and S.W. Thompson: Iron Steel Inst. Jpn. Int., 1995, vol. 35, pp. 937–45.

N.J. Kim, A.J. Yang, and G. Thomas: Metall. Trans. A, 1985, vol. 16A, pp. 471–74.

J.Y. Yoo and J.S. Woo: Proc. Int. Pipe Dreamer’s Conf., M. Toyoda and R. Denys, eds., Scientific Surveys, Ltd., Yokohama, Japan, 2002, pp. 441–56.

S. Okaguchi, H. Makino, M. Hamada, A. Yamamoto, T. Ikeda, I. Takeuchi, D.P. Fairchild, M.L. Macia, S.D. Papka, J.H. Stevens, C.W. Perersen, J.Y. Koo, N.V. Bangaru, and M.J. Luton: Proc. 13th Int. Offshore and Polar Engineering Conf., J.S. Chung and S. Prinsenberg, eds., Honolulu, HI, 2003, pp. 36–42.

B.C. Kim, S. Lee, N.J. Kim, and D.Y. Lee: Metall. Trans. A, 1991, vol. 22A, pp. 139–49.

S. Kim, S. Lee, Y.R. Im, H.C. Lee, S.J. Kim, and J.H. Hong: J. Kor. Inst. Met. Mater., 2002, vol. 42, pp. 939–48.

W. Späth: Impact Testing of Materials, Gordon and Breach, New York, NY, 1961, ch. IX.

L.N. Pussegoda, L. Malik, and W.R. Tyson: Can. Metall. Q., 1997, vol. 36, pp. 39–47.

G.E. Dieter: Mechanical Metallurgy, McGraw-Hill, London, 1988.

S.D. Papka, J.H. Stevens, M.L. Macia, D.P. Fairchild, and C.W. Petersen: Int. J. Offshore and Polar Eng., 2004, vol. 14, pp. 42–51.

T.L. Anderson: Fracture Mechanics—Fundamentals and Applications, CRC Press, Boca Raton, FL, 1995.

P.E. O’Donoghue, M.F. Kanninen, C.P. Leung, G. Demofonti, and S. Venzi: Int. J. Pressure Vessel Piping, 1997, vol. 70, pp. 11–25.

C.G. Lee, S.-J. Kim, B.-H. Song, and S. Lee: Met. Mater. Int., 2002, vol. 8, pp. 435–41.

C.-M. Kim, W.-S. Kim, and Y.-T. Kho: Met. Mater. Int., 2002, vol. 8, pp. 197–202.

D.J. Horsley: Eng. Fract. Mech., 2003, vol. 70, pp. 547–52.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hwang, B., Kim, Y.G., Lee, S. et al. Effects of microstructure on inverse fracture occurring during drop-weight tear testing of high-toughness X70 pipeline steels. Metall Mater Trans A 36, 371–387 (2005). https://doi.org/10.1007/s11661-005-0309-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0309-7