Abstract

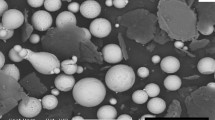

The microstructure and tribological properties of ferrous coatings applicable to cylinder bores were investigated in this study. Two kinds of ferrous powders were sprayed on Al-Si cast alloy (EN AlSi10Mg) substrate by atmospheric plasma spraying. Microstructural analysis showed that various Fe oxides were formed in the coatings. The presence of pores, unmelted particles, and Fe precipitates was also noticed. The pin-on-ring tribometer was used to carry out tribological tests under lubricated sliding conditions: sliding speed of 0.5 m/s, sliding distance of 5000 m, and normal load of 450 N. High porosity and the presence of larger and irregularly shaped pores as well as the amount of oxides were the controlling factors for the crack initiations and, consequently, the wear rate. Tribological properties of the coatings were compared with gray cast iron as a standard material for cylinder blocks and showed that, for the investigated conditions, both coatings could be an adequate substitution.

Similar content being viewed by others

References

G. Barbezat and R. Herber: Sulzer Tech. Rev., 2001, vol. 2, pp. 8–11.

J. Dohmen, F.G. Hermsen, G. Barbezat: MTZ, 2004, vol. 65, pp. 204–08

G. Barbezat: in Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple, C. Moreau, eds., ASM INTERNATIONAL, Materials Park, OH, 2003, pp. 139–42

G. Barbezat, J. Schmid: MTZ, 2001, vol. 62, pp. 314–20

G. Barbezat: Int. J. Auto. Technol., 2001, vol. 2, pp. 47–52

D.A. Rigney: Wear, 1994, vol. 175, pp. 63–69

S. Usmani, S. Sampath: Wear, 1999, vols. 225–229, pp. 1131–40

S.F. Wayne, S. Sampath, V. Anand: Tribol. Trans., 1994, vol. 37, pp. 636–40

L. Prchlik, S. Sampath: Wear, 2007, vol. 262, pp. 11–23

B. Hwang, S. Lee, J. Ahn: Mater. Sci. Eng. A, 2002, vol. 335, pp. 268–80

B. Hwang, J. Ahn, S. Lee: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2933–45

A. Rabiei, D.R. Mumm, J.W. Hutchinson, R. Schweinfest, M. Rühle, A.G. Evans: Mater. Sci. Eng. A, 1999, vol. 269, pp. 152–65

D.S. Rickerby, K.T. Scott, G. Eckold, and D. Lloyd-Thomas: in Proc. 1st Plasma-Technik-Symp., S. Sandneier, ed., Plasmatechnik AG, Wohlen, Switzerland, 1988, vol. 2, pp. 267–76

Turbojet Engine—Standard Practices Manual (PN 582005), Pratt & Whitney, East Hartford, CT, 2002

ASTM Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings, ASTM C633-01, ASTM International, West Conshohocken, PA, 2001

ISO 6621-3:2000 Internal Combustion Engines—Piston Rings—Part 3: Material Specifications, ISO, Geneva, Switzerland, 2000

ASTM Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test, ASTM G77-98, ASTM International, West Conshohocken, PA, 2001

Metco ® 92F High Carbon Iron Powder, Technical Bulletin, Metco Inc., New York, NY, 1975

Acknowledgments

This work was performed under the EUREKA program project E! 3240. The assistance of the partners of the project (Petar Drapšin, Serbia, for providing and preparing the test specimens), as well as the financial support received from the Republic of Serbia, Ministry of Science and Environmental Protection, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 30, 2008.

Rights and permissions

About this article

Cite this article

Vencl, A., Mrdak, M. & Banjac, M. Correlation of Microstructures and Tribological Properties of Ferrous Coatings Deposited by Atmospheric Plasma Spraying on Al-Si Cast Alloy Substrate. Metall Mater Trans A 40, 398–405 (2009). https://doi.org/10.1007/s11661-008-9693-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9693-0