Abstract

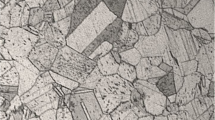

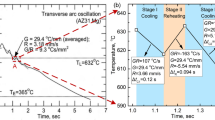

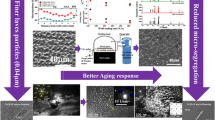

The microstructure and cast morphology of pulsed-current gas-metal arc (GMA) weld deposit of 1.6-mm-diameter aluminum (ER1100) and Al-Mg alloy (ER5183) filler wire have been studied on similar base material. The effect of the influence of the pulse frequency taken together with the peak and background currents and their durations, as defined by a dimensionless factor φ, varied in the range of 0.05 to 0.4 on the solidification behavior of the weld metal with respect to the morphology of its cast microstructure has been studied. The morphology of the dendrite as revealed under the scanning electron microscope (SEM) has been studied in reference to the change in the length of its coaxial growth, its aspect ratio, and its primary arm spacing, related to the variation in the factor φ. It is shown that the microstructure of the weld metal changes significantly with the change in the factor φ. It is also found that the variation in the mean current and heat input significantly affects the morphology of the dendrite, as defined here. The morphological characteristics of the dendrites have been correlated to the factor φ, the mean current, and the heat input. The dendrite arm spacing has been found to maintain a good correlation with the estimated cooling rate of the weld metal, in that it decreases with the increase in the cooling rate. At a given heat input, mean current, and φ, the Al-Mg alloy contains a comparatively larger fraction of finer dendrites with an appropriately similar morphology than does the aluminum weld deposit.

Similar content being viewed by others

References

E. Wiston: Data Sheets, IIW Manual, International Institute of Welding, 1974, p. 24

T. DebRoy and S.A. David: Rev. Mod. Phys., 1995, vol. 67 (1)

W. Gruhl, H. Cordier: Z. Metallkd., 1964, vol. 55, p. 557

F. Matsuda, K. Nakata, K. Tsukamoto, S. Johgan: Trans. JWRI, 1985, vol. 14 (2), p. 299

P.K. Ghosh, V. Sharma: Mater. Trans., JIM, 1991, vol. 32 (2), pp. 145–50

P.K. Ghosh, S.R. Gupta, P.C. Gupta, R. Rathi: Pract. Met., 1990, vol. 27, pp. 613–26

N.B. Potluri, P.K. Ghosh, P.C. Gupta, and Y.S. Reddy: Weld. J., 1996, vol. 75, pp. 62s–70s

P.K. Ghosh, S.R. Gupta, H.S. Randhawa: Int. J. Join. Mater., 2000, 12 (3), pp. 76–85

P.K. Ghosh: Int. J. Join. Mater., 1996, vol. 8 (4), pp. 157–61

P.K. Ghosh, B.K. Rai: ISIJ Int., 1996, vol. 36 (8), pp. 1036–45

H.S. Randhawa, P.K. Ghosh, S.R. Gupta: ISIJ Int., 1998, vol. 38 (3), pp. 276–84

P.K. Ghosh, B.K. Rai: Ind. Weld. J., 1998, vol. 31 (4), pp. 30–39

P.K. Ghosh, S.R. Gupta, H.S. Randhawa: Int. J. Join. Mater., 1999, vol. 11 (4), pp. 99–110

H.S. Randhawa, P.K. Ghosh, S.R. Gupta: ISIJ Int., 2000, vol. 40 (1), pp. 71–76

P.K. Ghosh, H.S. Randhawa, S.R. Gupta: Metall. Trans. A, 2000, vol. 31A (12), pp. 2247–59

P.K. Ghosh, L. Dorn, S.F. Goecke: Int. J. Join. Mater., 2001, vol. 13 (2), pp. 40–47

P. K. Ghosh, L. Dorn, Marc Hübner, and V.K. Goyal: J. Mater. Processing Technol., 2006, in press

P.K. Ghosh: Int. Welding Conference (IWC 99), on Welding and Allied Technology, New Delhi, India, Feb. 15–17, Indian Institute of Welding, Calcutta, 1999, pp. 18–27

M.F. Ashby, K.E. Easterling: Acta Metall., 1982, vol. 30, pp. 1969–78

H.M. Hussain, P.K. Ghosh, P.C. Gupta, N.B. Potluri: J. Mater. Process. Tech., 1997, vol. 9 (2), pp. 74–80

P.K. Ghosh, V.K. Goyal, H.K. Dhiman, M. Kumar: Sci. Technol. Weld. Join., 2006, vol. 11 (2), pp. 232–42

V.K. Goyal, P.K. Ghosh, and J.S. Saini: J. Mater. Process. Technol., 2006, in press

M.E. Glicksman: Fundamentals of Dendritic Microstructures, Aluminum Transformation Technology and Applications, Proc. 2nd Int. Symp., Buenos Aires, Argentina, Aug. 1981, ASM, Metals Park, OH, 1981, pp. 24–26

M.C. Flemings: Solidification Processing, McGraw-Hill Book Company, New York, NY, 1974

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 20, 2006.

Rights and permissions

About this article

Cite this article

Goyal, V., Ghosh, P. & Saini, J. Process-Controlled Microstructure and Cast Morphology of Dendrite in Pulsed-Current Gas-Metal Arc Weld Deposits of Aluminum and Al-Mg Alloy. Metall Mater Trans A 38, 1794–1805 (2007). https://doi.org/10.1007/s11661-007-9217-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9217-3