Abstract

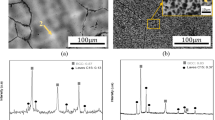

The kinetics of nitriding of Fe-2 wt pct V alloy was investigated as a function of time and temperature by exposing the alloy to a gas mixture of ammonia and hydrogen at constant nitriding potential 0.103 atm−1/2 at different nitriding temperatures, 520 °C, 550 °C, 580 °C, and 600 °C, for times up to 10, 10, 10, and 7 hours, respectively. The nitrided zone contains finely dispersed small vanadium-nitride precipitates in ferrite (α-Fe) grains. The nitrogen content within the nitrided zone is larger than expected on the basis of the vanadium content and the solubility of nitrogen in (stress-free) ferrite: excess nitrogen occurs. A model was developed that adequately predicts the evolution of the nitrogen concentration-depth profile of the nitrided layer. The model distinguishes quantitatively between the effects of mobile and immobile excess nitrogen, where immobile excess nitrogen is nitrogen adsorbed at the nitride platelet/matrix interface and mobile excess nitrogen is nitrogen dissolved in the matrix. The model has, as important (fit) parameters, the composition of the precipitated vanadium nitride, the effective diffusivity of nitrogen in the ferrite matrix surrounding the precipitates, and the solubility product of dissolved vanadium and dissolved nitrogen in the ferrite matrix. Analysis of the concentration-depth profile data at various nitriding temperatures exhibited the effect of the nitriding temperature on the amounts of mobile and immobile excess nitrogen.

Similar content being viewed by others

References

E.J. Mittemeijer, M.A.J. Somers: Surface Eng., 1997, vol. 13, p. 483

S.S. Hosmani, R.E. Schacherl, E.J. Mittemeijer: Acta Mater., 2006, vol. 54, p. 2783

R.E. Schacherl, P.C.J. Graat, E.J. Mittemeijer: Metall. Mater. Trans. A, 2004, vol. 35A, p. 3387

M.H. Biglari, C.M. Brakman, E.J. Mittemeijer, S. van der Zwaag: Phil. Mag. A, 1995, vol. 72, p. 931

S.S. Hosmani, R.E. Schacherl, E.J. Mittemeijer: Acta Mater., 2005, vol. 53, p. 2069

P.M. Hekker, H.C.F. Rozendaal, E.J. Mittemeijer: J. Mater. Sci., 1985, vol. 20, p. 718

B.J. Lightfoot, D.H. Jack: Proc. Conf. on Heat Treatment 1973, The Metals Society, London, 1975, pp. 59–65

C. Alves, J. de Anchieta Rodrigues, A. Eduardo Martinelli: Mater. Sci. Eng., 2000, vol. 279, p. 10

V.A. Philipps, A.U. Seybolt: Trans. TMS-AIME, 1968, vol. 242, p. 2415

M. Pope, P. Grieveson, K.H. Jack: Scand. J. Metall., 1973, vol. 2, p. 29.

W.D. Welch, S.H. Carpenter: Acta Metall., 1973, vol. 21, p. 1169.

A. Krawitz: Scripta Metall., 1977, vol. 11, p. 117

M.M. Yang, A.D. Krawitz: Metall. Trans. A, 1984, vol. 15A, p. 1545

T.C. Bor, A.T.W. Kempen, F.D. Tichelaar, E.J. Mittemeijer, E. van der Giessen: Phil. Mag. A, 2002, vol. 82, p. 971

M.E. Djeghlal, L. Barrallier: Ann. Chim. Sci. Mater., 2003, vol. 28, p. 43

M. Gouné, T. Belmonte, A. Redjaimia, P. Weisbecker, J.M. Fiorani, H. Michel: Mater. Sci. Eng. A, 2003, vol. 351, p. 23

H.H. Podgurski, F.N. Davis: Acta Metall., 1981, vol. 29, p. 1

M.A.J. Somers, R.M. Lankreijer, E.J. Mittemeijer: Phil. Mag. A, 1989, vol. 59, p. 353

M.H. Biglari, C.M. Brakman, E.J. Mittemeijer: Phil. Mag. A, 1995, vol. 72, p. 1281

M.H. Biglari, C.M. Brakman, M.A.J. Somers, W.G. Sloof, E.J. Mittemeijer: Z. Metallkd., 1993, vol. 84, p. 124

E.J. Mittemeijer, J.T. Slycke: Surf. Eng., 1996, vol. 12, p. 152

J.C. Grossman, A. Mizel, M. Côté, M.L. Cohen, S.G. Louie: Phys. Rev. B, 1999, vol. 60, p. 6343

A. Engström, L. Höglund, J. Ågren: Metall. Mater. Trans. A, 1994, vol. 25A, p. 1127.

C.M. Garzón, A.P. Tschiptschin: Mater. Sci. Technol., 2004, vol. 20, p. 915

J.L. Pouchau, F. Pichoir: La Recherche Aérospatial, 1984, vol. 3, pp. 167–92

W.B. Pearson: A Handbook of Lattice Spacings and Structures of Metals, Pergamon Press, London, 1968, vol. 2

J.D. Fast, M.B. Verrijp: J. Iron Steel Inst., 1954, vol. 126, p. 24

J.D. Kamminga, T.P.C. Klaver, K. Nakata, B.J. Thijsse, G.C.A.M. Janssen: J. Computer-Aided Mater. Design, 2003, vol. 10, p. 1

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 20, 2006.

Rights and permissions

About this article

Cite this article

Hosmani, S.S., Schacherl, R.E. & Mittemeijer, E.J. Kinetics of Nitriding Fe-2 Wt Pct V Alloy: Mobile and Immobile Excess Nitrogen. Metall Mater Trans A 38, 7–16 (2007). https://doi.org/10.1007/s11661-006-9046-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-9046-9