Abstract

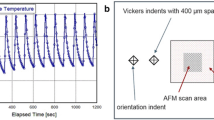

We demonstrate the rapid growth of grains in nonpassivated, sputtered Al-1 at. pct Si interconnects during 200 Hz thermal cycling induced by alternating current. Mean grain diameters were observed by use of automated electron backscatter diffraction (EBSD) to increase by more than 70 pct after an accumulated cycling time of less than 6 minutes over a temperature range of 200 °C, which corresponded to a total strain range of 4 × 10−3. Plasticity in growing grains primarily took the form of topography formation at the free surface and grain rotation, while consumed grains tended to retain relatively high dislocation content. Grain growth was characterized by means of pairwise comparisons in EBSD pattern quality across moving boundaries. Out of 92 cases where a grain was observed to grow into its neighbor, 61 cases indicated that the growing grain had a higher average pattern quality factor than that of the consumed grain, at the 95 pct confidence level. The results are consistent with a strain-induced boundary migration mechanism, wherein stored plastic strain energy differences from grain to grain drive growth, some of which was observed after only 10 seconds of cycling.

Similar content being viewed by others

References

Nabarro F.R.N. (1987) Theory of Crystal Dislocations, 2nd ed. Dover Publications, New York, NY, pp. 618–41

Huang A., Suo Z., Ma Q. (2002) J. Mech. Phys. Solids 50:1079–98

R.R. Keller, R. Mönig, C.A. Volkert, E. Arzt, R. Schwaiger, and O. Kraft: Stress-Induced Phenomena in Metallizations: 6th Int. Workshop, 2002, pp. 119–32

Flinn P. (1991) J. Mater. Res. 6:1498–1501

Gardner D.S., Flinn P.A. (1990) J. Appl. Phys. 67:1831–44

Thouless M., Gupta J., Harper J. (1993) J. Mater. Res. 8:1845–52

A. Witvrouw, P. Flinn, and K. Maex: MRS Symp. Proc.: Materials Reliability in Microelectronics VI, Materials Research Society, Pittsburgh, PA, 1996, vol. 428, pp. 519–24

Schwaiger R., Kraft O. (2003) Acta Mater. 51:195–206

Read D.T. (1998) Int. J. Fatigue 20:203–09

Mönig R., Keller R.R., Volkert C.A. (2004) Rev. Scientific Instrum. 75:4997–5004

Park Y.-B., Mönig R., Volkert C.A. (2006) Thin Solid Films 504:321–24

R.R. Keller, R.H. Geiss, Y.W. Cheng, and D.T. Read: MRS Symp. Proc.: Materials, Technology and Reliability of Advanced Interconnects, Materials Research Society, Pittsburgh, PA, 2005, vol. 863, pp. 295–300

ASTM F1259M-96R03 (2006) Annual Book of ASTM Standards, ASTM, Philadelphia, PA, vol. 10.04

Humphreys F. (2001) J. Mater. Sci. 36:3833–54

NIST/SEMATECH e-Handbook of Statistical Methods, http://www.itl.nist.gov/div898/handbook/

Fayad W., Andleigh V., Thompson C.V., Frost H.J. (1998) MRS Symp. Proc.: Materials Reliability in Microelectronics VIII 516:159–64

Silcox J., Whelan M.J. (1960) Phil. Mag. 5:1–28

System manufactured by EDAX/TexSEM Labs. Commercial product names are provided in this work solely to clarify the nature of the measurements, specifically image quality, and do not imply endorsement by NIST or the United States Government

Krieger Lassen N.C. (1996) Mater. Sci. Technol. 12:837–43

Keller R.R., Roshko A., Geiss R., Bertness K., Quinn T.P. (2004) Microelectron. Eng. 75:96–102

Longworth H., Thompson C.V. (1991) J. Appl. Phys. 69:3929–40

Mullins W.W. (1958) Acta Metall. 6:414–27

Verhoeven J.D. (1975) Fundamentals of Physical Metallurgy. Wiley, New York, NY, pp. 169–215

O.V. Kononenko and V.N. Matveev: MRS Symp. Proc.: Materials Reliability in Microelectronics VI, 1996, vol. 428, pp. 231–36

Beck P.A., Sperry P.R. (1950) J. Appl. Phys. 21:150–52

C.C. Battaile, T.E. Buchheit, E.A. Holm, G.W. Wellman, and M.K. Neilsen: MRS Symp. Proc.: Multiscale Modeling of Materials, Materials Research Society, Pittsburgh, PA, 1999, vol. 538, pp. 269–73

Kuhlmann-Wilsdorf D., Wilsdorf H.G.F. (1963) Electron Microscopy and Strength of Crystals. Interscience, New York, NY, pp. 575–604

Sanchez J.E., Jr., Arzt E. (1992) Scripta Metall. Mater. 27:285–90

Acknowledgments

We thank the NIST Office of Microelectronics Programs and the National Research Council Post-Doctoral Research Program for support. We thank D.S. Finch (AISthesis, LLC) for preparation of TEM specimens by FIB. This work is a contribution of the United States Department of Commerce and is not subject to copyright in the United States.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given in the symposium entitled “Deformation and Fracture from Nano to Macro: A Symposium Honoring W. W. Gerberich's 70th Birthday” which occurred during the TMS Annual Meeting, March 12–16, 2006, in San Antonio, Texas and was sponsored by the Mechanical Behavior of Materials and Nanomechanical Behavior Committees of TMS.

Rights and permissions

About this article

Cite this article

Keller, R., Geiss, R., Barbosa, N. et al. Strain-Induced Grain Growth during Rapid Thermal Cycling of Aluminum Interconnects. Metall Mater Trans A 38, 2263–2272 (2007). https://doi.org/10.1007/s11661-006-9017-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-9017-1