Abstract

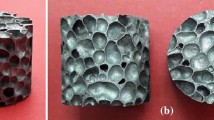

The dynamic compressive behavior of an open-cell commercially pure aluminum foam was experimentally investigated with a split Hopkinson bar (SHPB) and numerically simulated using the finite element (FE) method. It is found that the flow stress increases with increasing strain rate, demonstrating the existence of strain rate dependence in the present aluminum foam. This dependence is believed to originate from the polygonal pore architecture, the relatively high density, the intrinsic property of aluminum, as well as the friction force between the contacted cell walls.

Similar content being viewed by others

References

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties, 2nd ed., Cambridge University Press, Cambridge, United Kingdom, 1997, pp. 1–10.

J. Banhart: Progr. Mater. Sci., 2001, vol. 46, pp. 559–632.

C. San March and A. Mortensen: Acta Mater., 2001, vol. 49, pp. 3959–69.

Sigit Santosa and Tomasz Wierzbicki: J. Mech. Phys. Solids, 1998, vol. 46, pp. 645–69.

K.A. Dannemann, J. Lankford Jr.: J. Mater. Sci. Eng., 2000, vol. 293, pp. 157–64.

T. Mukai, H. Kanahashi, T. Miyoshi, M. Mabuchi, and T.G. Nieh: Scripta Mater., 1999, vol. 40, pp. 921–27.

Kathryn A. Dannemann and James Lankford, Jr.: Mater. Sci. Eng. A, 2000, vol. 293, pp. 157–64.

A. Paul and U. Ramamurty: Mater. Sci. Eng. A, 2000, vol. 281, pp. 1–7.

H. Kannahashi and T. Mukai, Y. Yamada, K. Shimojima, M. Mabuchi, T.G. Nieh, and K. Higashi: Mater. Sci. Eng., A2000, vol. 280, pp. 349–53.

V.S. Deshpande and N.A. Fleck: Int. J. Impact Eng., 2000, vol. 24, pp. 277–98.

I.W. Hall, M. Guden, and C.J. Yu: Scripta Mater., 2000, vol. 43, pp. 515–21.

P.J. Tan, J.J. Harridan, and S.R. Reid: Mater. Sci. Technol., 2002, vol. 18, pp. 480–88.

J. Gassan, W. Harwick, and D. Girlich: J. Mater. Sci. Lett., 2001, vol. 20, pp. 1047–48.

F.S. Han, Z.G. Zhu, and J.C. Gao: Metal. Mater. Trans. A, 1998, vol. 29A, p. 2497–502.

W.E. Warren and A.M. Crank: J. Appl. Mech., 1988, vol. 55, pp. 341–49.

R.M. Christensen: J. Mech. Phys. Solids, 1986, vol. 34, pp. 563–78.

W.E. Warren and A.M. Crank: J. Appl. Mech., 1997, vol. 64, pp. 787–94.

H.X. Zhu, J.F. Knott, and N.J. Mills: J. Mech. Phys. Solids, 1997, vol. 45, pp. 319–25.

J.L. Grenestedt: Int. J. Solids Struct., 1999, vol. 36, pp. 1471–501.

A.P. Roberts and E.J. Garboczi: Proc. R. Soc., 2002, vol. 458, pp. 1033–54.

A.P. Roberts and E.J. Garboczi: Acta Mater., 2001, vol. 49, pp. 189–97.

A.P. Roberts and E.J. Garboczi: J. Mech. Phys. Solids, 2002, vol. 50, pp. 33–55.

F.S. Han, H.F. Cheng, J.X. Wang, and Q. Wang: Scripta Mater., 2004, vol. 50, pp. 13–17.

LS-DYNA Theoretical Manual, Livermore Software Technology Co., 1998, p. 225.

ANSYS/LS-DYNA User’s Guide, ANSYS Inc.

Metals Handbook, 10th ed., vol. 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM INTERNATIONAL, Materials Park, OH, 1990, p. 102.

C.R. Calladine and R.W. English: Int. J. Mech. Sci., 1984, vol. 26, pp. 689–92.

U.S. Lindholm: J. Mech. Phys. Solids, 1964, vol. 12, pp. 317–35.

S.S. Hu, W. Wang, Y. Pan, and Y.H. Li: Explosion Shock Waves, 2003, vol. 23, pp. 13–18 (in Chinese).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Han, F., Cheng, H., Wang, Q. et al. The strain rate effect of an open cell aluminum foam. Metall Mater Trans A 36, 645–650 (2005). https://doi.org/10.1007/s11661-005-0180-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0180-6