Abstract

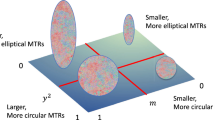

Notched-tension tests were conducted on Ti-6Al-4V samples with a colony-alpha microstructure to determine the effect of the stress state on cavitation during hot working of alpha/beta titanium alloys. The experiments were complemented by finite-element-method analyses to establish the local stress state, strain, and damage factor for different areas within each sample. A critical damage factor, defined by a modified Cockcroft-and-Latham criterion, was found to be applicable for the prediction of cavity initiation for the different notch geometries. Measured cavity growth rates were also correlated to the stress state (i.e., ratio of mean-to-effective stress, σ M /σ e ) and compared to predictions of prior models. Model predictions showed reasonable agreement with measurements at low levels of stress triaxiality, but exhibited some deviations at higher values of σ M /σ e . The differences were attributed to differences in the properties of the present material and those assumed in deriving the models as well as the neglect of cavity interaction in one of the models. The results were summarized in terms of a processing map, which delineates the initiation of cavities and their size as a function of the stress state and effective strain.

Similar content being viewed by others

References

P.D. Nicolaou, R.E. Bailey, and S.L. Semiatin: in Handbook of Workability and Process Design, G.E. Dieter, H.A. Kuhn, and S.L. Semiatin, eds., ASM INTERNATIONAL, Materials Park, OH, 2003, pp. 68–85.

C.C. Bampton and J.W. Edington: J. Eng. Mater. Technol., 1983, vol. 105, pp. 55–60.

M.B. Taylor, H.M. Zbib, and M.A. Khaleel: Int. J. Plasticity, 2002, vol. 18, pp. 415–42.

M.M.I. Ahmed and T.G. Langdon: Metall. Trans. A, 1977, vol. 8A, pp. 1832–33.

M.J. Stowell: in Superplastic Forming of Structural Alloys, N.E. Paton and C.H. Hamilton, eds., TMS-AIME, Warrendale, PA, 1982, pp. 321–26.

B.P. Kashyap and M.K. Mukherjee: Res. Mech., 1986, vol. 17, pp. 293–355.

P.D. Nicolaou and S.L. Semiatin: Acta Mater., 2003, vol. 51, pp. 613–23.

R. Verma, P.A. Friedman, A.K. Ghosh, S. Kim, and C. Kim: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1889–98.

J. Pilling and N. Ridley: in Superplasticity in Aerospace, H.C. Heikkenen and T.R. McNelley, eds., TMS, Warrendale, PA, 1988, pp. 183–97.

G.Q. Tong and K.C. Chan: Mater. Sci. Eng. A, 2002, vol. A325, pp. 79–86.

D.J. Zhou, J. Lian, and M. Suery: Mater. Sci. Technol., 1988, vol. 4, pp. 348–55.

H. Agarwal, A.M. Gokhale, S. Graham, and M.F. Horstemeyer: Mater. Sci. Eng. A, 2003, vol. A341, pp. 35–42.

J.W. Hancock and A.C. Mackenzie: J. Mech. Phys. Solids, 1976, vol. 14, pp. 107–69.

P.D. Nicolaou, R.L. Goetz, J.D. Miller, and S.L. Semiatin: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2397–2400.

DEFORM TM Users Manual, Version 7.1, Scientific Forming Technologies Corporation, Columbus, OH, 1993.

S.L. Semiatin, V. Seetharaman, and I. Weiss: Mater. Sci. Eng. A, 1998, vol. A243, pp. 1–24.

S.L. Semiatin, V. Seetharaman, A.K. Ghosh, E.B. Shell, M.P. Simon, and P.N. Fagin: Mater. Sci. Eng. A, 1998, vol. A256, pp. 92–110.

P.W. Bridgman: Studies in Large Plastic Flow and Fracture, McGraw-Hill, New York, NY, 1952.

M.G. Cockcroft and D.J. Latham: J. Inst. Met., 1968, vol. 96, pp. 33–39.

S.L. Semiatin, R.L. Goetz, E.B. Shell, V. Seetharaman, and A.K. Ghosh: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1411–24.

S.L. Semiatin, P.D. Nicolaou, T.R. Bieler, and A.K. Ghosh: Mater. Techn., 2002, Nos. 5–6, pp. 31–40.

P.D. Nicolaou and S.L. Semiatin: Acta Mater., 2000, vol. 48, pp. 3441–50.

P.D. Nicolaou and S.L. Semiatin: J. Mater. Sci., 2001, vol. 36, pp. 5155–59.

J.R. Rice and D.M. Tracey: J. Mech. Phys. Solids, 1969, vol. 17, pp. 201–17.

J. Pilling and N. Ridley: Acta Metall., 1986, vol. 34, pp. 669–79.

T.R. Bieler and S.L. Semiatin: in Lightweight Alloys for Aerospace Applications VI (PDF Only Edition), K.V. Jata, ed., TMS, Warrendale, PA, 2001, pp. 161–70.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nicolaou, P.D., Goetz, R.L. & Semiatin, S.L. Influence of stress state on cavitation during hot working of Ti-6Al-4V. Metall Mater Trans A 35, 655–663 (2004). https://doi.org/10.1007/s11661-004-0377-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0377-0