Abstract

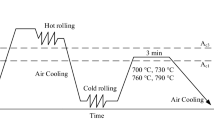

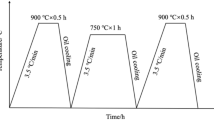

This research studied the effects of heat treatment and testing temperature on fracture mechanics behavior of Si-modified CA-15 martensitic stainless steel (MSS), which is similar to AISI 403 grade stainless steel, which has been widely used in wall and blanket structures and in the pipe of nuclear power plant reactors, turbine blades, and nozzles. The results indicated that fracture toughness of low-Si CA-15 MSS is better than that of AISI 403. The specimens of the low-Si CA-15 MSS after austenitization at 1010 °C and then tempering at 300 °C have higher plane-strain fracture toughness (K IC ) values for both 25 °C and −150 °C testing temperatures. However, the specimens tested at 150 °C cannot satisfy the plane-strain fracture toughness criteria. The fatigue crack growth rate is the slowest after austenitization at 1010 °C for 2 hours and tempering at 400 °C. Observing the crack propagation paths using a metallographic test, it was found that the cracking paths preferred orientation and branched along ferrite phase, owing to martensite-phase strengthening and grain-boundary-carbide retarding after 300 °C to 400 °C tempering. Also, transmission electron microscopy (TEM), scanning electron microscopy (SEM), and X-ray diffraction analysis were performed to correlate the properties attained to the microstructural observation.

Similar content being viewed by others

References

P.R. Sreenivasan, S.K. Ray, S.L. Mannan, and P. Rodriguez: J. Nucl. Mater., 1996, vol. 228, pp. 338–45.

C. Gupta, J.S. Dubey, S. Ganguly, A.R. Biswas, Y.V. Kamat, and J.K. Chakravartty: High Temp. Mater. Processes, 1997, vol. 16 (1), pp. 65–75.

ASM Handbook, vol. 1, Properties and Selection: Irons, Steels, and High-Performance Alloys, 10th ed., ASM, Materials Park, OH, 1990, pp. 908–29.

Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials, ASTM E399, ASTM, Philadelphia, PA, 1997, pp. 408–38.

ASM Handbook, vol. 4, Heat Treating, ASM, Materials Park, OH, 1991, pp. 789–92.

“Constant-Load-Amplitude Fatigue Crack Growth Rate above 1028 mm/cycle,” ASTM E647, ASTM, Philadelphia, PA, 1984, pp. 716–30.

“Standard Practice for R-Curve Determination,” ASTM E561, ASTM, Philadelphia, PA, 1977, pp. 489–501.

M.C. Balmforth and J.C. Lippold: Welding J., 1998, pp. 1–7.

Baihe Miao, D.O. Northwood, L.C. Lim, and M.O. Lai: Mater. Sci. Eng. A, 1993, vol. A171, pp. 21–33.

P.C. Paris and F. Erdogan: Trans. ASME J. Basic Eng., 1963, vol. 85, p. 528.

A.F. Hiber: AFS Trans., 1978, vol. 86, p. 143.

C. Gupta, S.L. Wadekar, J.S. Dubey, R.T. Savalia, K.S. Balakrishnan, S. Anantharaman, Y.V. Kamat, and J.K. Chakravartty: High Temp. Mater. Processes, 1997, vol. 16 (2), pp. 149–57.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hsu, CH., Lee, SC. & Teng, HY. Effects of heat treatment and testing temperature on fracture mechanics behavior of low-Si CA-15 stainless steel. Metall Mater Trans A 35, 471–480 (2004). https://doi.org/10.1007/s11661-004-0358-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0358-3