Abstract

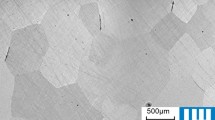

Shape-memory properties of equiatomic NiTi, Ni45Ti50Cu5, and Ni25Ti50Cu25 ribbons made by melt spinning have been studied by temperature inducing the martensitic transformation under constant tensile loads. Recoverable strains above 4 pct can be obtained under ∼100 MPa loads for the NiTi and Ni45Ti50Cu5 ribbons, transforming to B19’ martensite. The B19 martensite is formed in the Ni25Ti50Cu25 ribbon after crystallization, and according to the lowering in transformation strain as Cu content increases, the recoverable strain is close to 2.5 pct for ∼150 MPa load. The transformation temperatures exhibit a linear dependence on the applied stress, which can be quantitatively described by means of a Clausius-Clapeyron type equation. The NiTi and Ni45Ti50Cu5 ribbons exhibited some degree of two-way shape-memory effect (TWSME) after thermomechanical cycling. Texture analyses performed on the different ribbons allow us to better understand the transformation strains obtained in each ribbon. The amounts of shape-memory effect (SME) and nonrecoverable strain shown by the studied ribbons are of the same order as those already observed in bulk materials, which makes melt spinning an ideal substitute to complicated manufacturing processes if really thin samples are needed. However, applicable stresses in melt-spun ribbons are limited by a relatively “premature” brittle fracture caused by irregularities in ribbon thickness.

Similar content being viewed by others

References

J. Beyer and J.H. Mulder: Mater. Res. Soc. Symp. Proc., 1995, vol. 360, pp. 443–54.

H. Hosoda, T. Fukul, K. Inoue, Y. Mishima, and T. Suzuki: Mater. Res. Soc. Symp. Proc., 1997, vol. 459, pp. 287–93.

V.A. Lobodyuk and M.M. Medyukh: Met. Phys. Adv. Technol., 1997, vol. 16, pp. 493–503.

M. Piao, S. Miyazaki, K. Otsuka, and N. Nishida: Mater. Trans. JIM, 1992, vol. 33, pp. 337–45.

K. Otsuka and C.M. Wayman: Shape Memory Materials, 1st ed., Cambridge University Press, Cambridge, United Kingdom, 1998, pp. 49–96.

W.J. Moberly and K.N. Melton: Engineering Aspects of Shape Memory Alloys, 1st ed., Butterworth-Heinemann Ltd., Essex, 1990, pp. 46–57.

D.R. Angst, P.E. Thoma, and M.Y. Kao: J. Phys. IV, 1995, vol. C8, pp. 747–52.

S.F. Hsieh and S.K. Wu: Mater. Characterization, 1998, vol. 41, pp. 151–62.

R. Santamarta, C. Seguí, J. Pons, and E. Cesari: Scripta Mater., 1999, vol. 41, pp. 867–72.

E. Cesari, J. Pons, R. Santamarta, C. Seguí, D. Stróz, and H. Morawiec: Proc. XVIII Conf. on Applied Crystallography, World Scientific, Singapore, 2001, pp. 171–85.

Y. Furuya, M. Matsumoto, and T. Matsumoto: Proc. Int. Conf. on Martensitic Transformation, Monterey Institute for Advanced Studies, Monterey, CA, 1993, pp. 905–09.

S.D. Wang, X.Z. Wu, J.P. Zhang, H.Q. Su, J.L. Jin, and B.T. Song: Trans. Mater. Res. Soc. Jpn., 1994, vol. 18B, pp. 1061–64.

R. Santamarta, E. Cesari, J. Pons, C. Seguí, P. Ochin, and R. Portier: Proc. Solid-Solid Phase Transformation ’99, The Japan Institute of Metals, Sendai, 1999, pp. 1076–79.

P. Wollants, M. De Bonte, and J.R. Roos: Z. Metallkd., 1979, vol. 70, pp. 113–17.

S. Miyazaki and K. Otsuka: Metall. Trans. A, 1986, vol. 17A, pp. 53–63.

C.B. Stachowiak and P.G. McCormick: Acta Metall., 1988, vol. 36, pp. 291–97.

P. Sittner and V. Novák: Int. J. Plasticity, 2000, vol. 16, pp. 1243–68.

K. Bhattacharya and R.V. Kohn: Acta Mater., 1996, vol. 44, pp. 529–42.

P. Olier, J.C. Brachet, J.L. Bechade, C. Foucher, and G. Guénin: J. Phys. IV, 1995, vol. C8, pp. 741–46.

G. Airoldi, T. Ranucci, G. Riva, and A. Sciacca: J. Phys.-Condens. Mat., 1995, vol. 7, pp. 3709–20.

T. Goryczka: Ph.D. Thesis, University of Silesia, Katowice, 2001.

C.S. Barret and T.B. Massalski: Structure of Metals, 3rd ed., McGraw-Hill, New York, NY, 1966.

H. Rösner, P. Schlosmacher, A.V. Sheliakov, and A.M. Glezer: Scripta Mater., 2000, vol. 43, pp. 871–76.

T.H. Nam, T. Saburi, and K. Shimizu: Mater. Trans. JIM, 1990, vol. 31, pp. 959–67.

T.H. Nam, T. Saburi, Y. Nakata, and K. Shimizu: Mater. Trans. JIM, 1990, vol. 31, pp. 1050–56.

T. Goryczka, M. Karolus, P. Ochin, and H. Morawiec: J. Phys. IV, 2001, vol. 11, pp. 345–50.

A.V. Shelyakov, Y.A. Bykovsky, N.M. Matveeva, and Y.K. Kovneristy: J. Phys. IV, 1995, vol. C8, pp. 713–16.

Y. Liu and H. Yang: Mater. Sci. Eng. A, 1999, vol. A260, pp. 240–45.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Santamarta, R., Cesari, E., Pons, J. et al. Shape memory properties of Ni-Ti based melt-spun ribbons. Metall Mater Trans A 35, 761–770 (2004). https://doi.org/10.1007/s11661-004-0004-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0004-0