Abstract

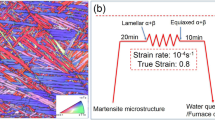

An investigation on the formation of α″ martensite and its influence on Young’s modulus and mechanical properties of forged Ti-29Nb-13Ta-4.6Zr (wt pct) alloy is reported in this article. For ice-water-quenched specimens after solution treatment at 1023, 1123, and 1223 K in the single β-phase field for 1.8, 3.6, 14.4, and 28.8 ks, X-ray diffraction and internal friction measurements showed that the volume fraction of the α″ martensite changes with both solution temperature and time. This effect has been attributed mainly to the influence of grain size of the β-parent phase on the stability of the β phase and, consequently, on the martensitic start (M s) temperature. A critical grain size of 40 µm was identified for the β phase, below which the martensitic transformation is largely suppressed because of low M S temperature. With the β grain size increasing above this critical value, the volume fraction of the α″ martensite increases significantly at first and then decreases gradually with further grain growth. The α″ martensite was shown to possess good ductility and, compared to the β phase, lower strength and hardness but nearly identical Young’s modulus in the studied alloy.

Similar content being viewed by others

References

S.G. Steinemann: in Titanium ’84: Science and Technology, G. Lütjering, U. Zwicker, and W. Bunk, eds., Deutsche Gesellschaft Für Metallkunde EV, Munich, 1985, vol. 2, p. 1373.

D.R. Crapper, D.R. Mclachlan, B. Farnell, H. Galin, S. Karlik, G. Eichhorn, and U. De Boni: in Biological Aspects of Metals and Metals-Related Diseases, B. Sarkar, ed., Raven Press, New York, 1993, p. 209.

A.R. Dujovne, J.D. Bobyn, J.J. Krygier, J.E. Miller, and C.E. Brooks: J. Arthroplasty, 1993, vol. 8, p. 7.

A.K. Mishra, J.A. Davidson, R.A. Poggie, P. Kovacs, and T.J. Fitzgerald: in Medical Application of Titanium and Its Alloys: The Material and Biological Issues, J.E. Lemons, ed., ASTM STP, ASTM, West Conshohocken, PA, 1996, vol. 1272, p. 96.

M. Long and H.J. Rack: Biomaterials, 1998, vol. 19, p. 1621.

M. Niinomi: Mater. Sci. Eng. A, 1998, vol. 243A, p. 231.

D.L. Moffat and D.C. Larbalestier: Metall. Trans. A, 1988, vol. 19A. p. 1677.

E.W. Collings: Physical Metallurgy of Titanium Alloys, ASM, Metals Park, OH, 1984.

W.F. Ho, C.P. Ju, and J.H.C. Lin: Biomaterials, 1999, vol. 20, p. 2115.

S.G. Fedotov: in Titanium Sci. Technol., R.I. Jaffee and H.M. Burte, eds., Plenum Press, New York, NY, 1973, p. 871.

W.H. Graft and W. Rostoker: Symposium on Titanium: Presented at the Second Pacific Area National Meeting, ASTM, West Conshohocken, PA, 1957, p. 130.

Y.T. Lee and G. Welsch: Mater. Sci. Eng. A, 1990, vol. 128A, p. 77.

T. Sugimoto, K. Kamei, and S. Komatsu: in Titanium Science and Technology, G. Lütjering, U. Zwicker, and W. Bunk, eds., Deutsche Gesellschaft Für Metallkunde EV, Munich, 1985, p. 1543.

A. Hiromoto, T. Daikoku, and S. Ueda: in Titanium Science and Technology, G. Lütjering, U. Zwicker, and W. Bunk, eds., Deutsche Gesellschaft Für Metallkunde EV, Munich, 1985, 1984, vol. 3, p. 1683.

Z. Fan: Scripta Metall. Mater., 1993, vol. 29, p. 1427.

Y.L. Hao, M. Niinomi, D. Kuroda, K. Fukunaga, Y.L. Zhou, R. Yang, and A. Suzuki: unpublished research, 2002.

Introduction of Young’s Modulus Measure System (JE-RT 3), Technical Manual, Nippon Techno-Plus Co., Ltd., Japan, p. 7.

M. Umemoto and W.S. Owen: Metall. Trans. A, 1974, vol. 2A, p. 2041.

S. Kajiwara: Metall. Trans. A, 1986, vol. 17A, p. 1693.

A. Artemev, Y. Wang, and A.G. Khachaturyan: Acta. Mater., 2000, vol. 48, p. 2503.

Y.K. Lee and C.S. Choi: Metall. Mater. Trans. A, 2000, vol. 31A, p. 355.

T. Grosdidier, Y. Combres, E. Gautier, and M.J. Philippe: Metall. Mater. Trans. A, 2000, vol. 31A, p. 1095.

W. Jin and C.S. Choi: J. Kor. Inst. Metall. Trans., 1992, vol. 30, p. 68.

Y.K. Lee and C.S. Choi: Metall. Trans. A, 2000, vol. 31A, p. 2735.

S. Kajiwara: Metall. Trans. A, 1986, vol. 17A, p. 1693.

A.R. Boccaccini: Z. Metallkd., 1997, vol. 88, p. 23.

Y. Song, R. Yang, D. Li, W.T. Wu, and Z.X. Guo: Mater. Sci. Eng. A, 1999, vol. 260A, p. 269.

J.L. Murray: Phase Diagrams of Binary Titanium Alloys, ASM INTERNATIONAL, Metals Park, OH, 1987.

Z. Fan, P. Tsakiropoulos, P.A. Smith, and A.P. Miodownik: Phil. Mag. A, 1993, vol. 67A, p. 515.

S. Ankem and H. Margolin: Metall. Trans. A, 1986, vol. 17A, p. 2209.

Y.T. Lee, M. Peters, and G. Welsch: Metall. Trans. A, 1991, vol. 22A, p. 709.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hao, Y.L., Yang, R., Niinomi, M. et al. Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr in relation to α″ martensite. Metall Mater Trans A 33, 3137–3144 (2002). https://doi.org/10.1007/s11661-002-0299-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0299-7