Abstract

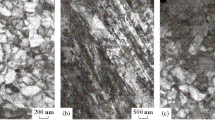

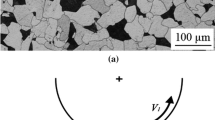

An investigation into the production of ultrafine (1 µm) equiaxed ferrite (UFF) grains in low-carbon steel was made using laboratory rolling, compression dilatometry, and hot torsion techniques. It was found that the hot rolling of thin strip, with a combination of high shear strain and high undercooling, provided the conditions most suitable for the formation of this type of microstructure. Although high strains could be applied in compression and torsion experiments, large volume fractions of UFF were not observed in those samples, possibly due to the lower level of undercooling achieved. It is thought that ferrite refinement was due to a strain-induced transformation process, and that ferrite grains nucleated on parallel and linear deformation bands that traversed austenite grains. These bands formed during the deformation process, and the undercooling provided by the contact between the strip and the work rolls was sufficient to drive the transformation to homogeneous UFF grains.

Similar content being viewed by others

References

R.K. Gibbs, P.D. Hodgson, and B.A. Parker: Morris E. Fine Symp., P.K. Liaw, J.R. Weertman, H.L. Marcus, and J.S. Santner, eds., TMS, Warrendale, PA, 1991, pp. 73–77.

R. Priestner and P.D. Hodgson: Mater. Sci. Technol., 1992, vol. 8, pp. 849–54.

R. Priestner and E. De los Rios: Met. Technol., 1980, vol. 7, pp. 309–15.

R. Priestner and L. Ali: Mater. Sci. Technol., 1993, vol. 9, pp. 135–41.

R. Priestner: Thermomechanical Processing of Austenite, A.J. DeArdo, G.A. Ratz, and P.J. Wray, eds., TMS-AIME, Warrendale, PA, 1981, pp. 455–66.

B. Mintz, S. Yue, and J.J. Jonas: Int. Mater. Rev., 1991, vol. 36, pp. 187–217.

H. Yada, Y. Matsumura, and K. Nakajima: U.S. Patent No. 4,466,842, 1984.

J.H. Beynon, R. Gloss, and P.D. Hodgson: Mater. Forum, 1992, vol. 16, pp. 37–42.

P.D. Hodgson, M.R. Hickson, and R.K. Gibbs: Mater. Sci. Forum, 1998, vols. 284–286, pp. 63–72.

P.D. Hodgson, M.R. Hickson, and R.K. Gibbs: Scripta Mater., 1999, vol. 40, pp. 1179–84.

P.D. Hodgson, D.C. Collinson, and B. Perrett: Proc. 7th Int. Symp. on Physical Simulation of Casting, Hot Rolling and Welding, H.G. Suzuki, T. Sakai, and F. Matsuda, eds., NRIM, Tsukuba, Japan, 1997, pp. 219–29.

P.D. Hodgson, R.M. Traill, R.K. Gibbs, J. Grace, and C.H.J. Davies: 2nd Int. Conf. Modelling of Metal Rolling Processes, J.H. Beynon, P. Ingham, H. Teichert, and K. Waterson, eds., Institute of Materials, London, 1996, pp. 345–52.

H. Yada, Y. Matsumura, and T. Senuma: Int. Conf. Martensitic Transformations, Japan Institute of Metals, Tokyo, Japan, 1986, pp. 515–20.

Y. Matsumura and H. Yada: Trans. Iron Steel Inst. Jpn., 1987, vol. 27, pp. 492–98.

H. Yada, Y. Matsumura, and T. Senuma: Thermec ’88—Int. Conf. Physical Metallurgy of Thermomechanical Processing of Steels and Other Materials, I. Tamura, ed., ISIJ, Tokyo, 1988, pp. 200–07.

H. Yada, C. Li, H. Yamagata, and K. Tanaka: Thermec ’97—Int. Conf. Physical Metallurgy of Thermomechanical Processing of Steels and Other Materials, T. Chandra, ed., TMS, Warrendale, PA, 1997, pp. 765–70.

B. Mintz and J.J. Jonas: Mater. Sci. Technol., 1994, vol. 10, pp. 721–27.

B. Mintz, J. Lewis and J.J. Jonas: Mater. Sci. Technol., 1997, vol. 13, pp. 379–88.

J. Lewis, J.J. Jonas, and B. Mintz: Iron Steel Inst. Jpn. Int., 1998, vol. 38, pp. 300–09.

H. Mabuchi, T. Ishikawa, and Y. Nomiyama: Int. Symp. on Accelerated Cooling/Direct Quenching of Steels, R. Asfahani, ed., ASM INTERNATIONAL Materials Park, OH, 1997, pp. 43–50.

S. Gohda, K. Watanabe, and Y. Hashimoto: Trans. Iron Steel Inst. Jpn., 1981, vol. 21, pp. 6–15.

P.J. Hurley, B.C. Muddle, P.D. Hodgson, C.H.J. Davies, B.P. Wynne, P. Cizek, and M.R. Hickson: Mater. Sci. Forum, 1998, vols. 284–286, pp. 159–66.

P.J. Hurley, P.D. Hodgson, and B.C. Muddle: Scripta Mater., 1999, vol. 40, pp. 433–38.

M.R. Hickson, R.K. Gibbs, and P.D. Hodgson: BHP Research Melbourne, Australia, unpublished research, 1994.

R.W.K. Honeycombe and H.K.D.H. Bhadeshia: Steels—Microstructure and Properties, 2nd ed., Edward Arnold, London, 1995, p. 217.

K. Kato, Y. Saito, and T. Sakai: Trans. Iron Steel Inst. Jpn., 1984, vol. 24, pp. 1050–54.

T. Sakai, Y. Saito, M. Matsuo, and K. Kawasaki: Iron Steel Inst. Jpn. Int., 1991, vol. 31, pp. 86–94.

X.J. Zhang, P.D. Hodgson, and P.F. Thomson: J. Mater. Proc. Technol., 1996, vol. 60, pp. 615–19.

K. Tsuzaki, K. Young-Soo, and T. Maki: Proc. 7th Int. Symp. on Physical Simulation of Casting, Hot Rolling and Welding, H.G. Suzuki, T. Sakai, and F. Matsuda, eds., NRIM, Tsukuba, Japan, 1997, pp. 169–76.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hickson, M.R., Hurley, P.J., Gibbs, R.K. et al. The production of ultrafine ferrite in low-carbon steel by strain-induced transformation. Metall Mater Trans A 33, 1019–1026 (2002). https://doi.org/10.1007/s11661-002-0203-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0203-5