Abstract

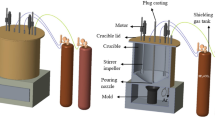

The AA7075 alloys reinforced with SiC and without SiC particles were fabricated by a pressureless infiltration method, and then, their tensile properties and microstructures were analyzed. The spontaneous infiltration of molten metal at 800 °C for 1 hour under a nitrogen atmosphere made it possible to fabricate 7075 Al matrix composite reinforced with SiC, as well as a control 7075 Al without SiC. A significant strengthening even in the control alloy occurred due to the formation of in-situ AlN particle even without an addition of SiC particles. Composite reinforced with SiC particles exhibited higher strength values than the control alloy in all aging conditions (underaged (UA), peak-aged (PA), and overaged (OA)), as well as a solution treated condition. Spontaneous infiltration was further prompted owing to the combined effect of both Mg and Zn. This may lead to an enhancement of wetting between the molten alloy and the reinforcement. Consequently, strength improvement in a composite may be attributed to good bond strength via enhancement of wetting. The grain size of the control alloy is greatly decreased to about 2.5 µm compared to 10 µm for the commercial alloy. In addition, the grain size in the composite is further decreased to about 2 µm. These grain refinements contributed to strengthening of the control alloy and the composite.

Similar content being viewed by others

References

A. Mortensen and I. Jin: Int. Mater. Rev., 1992, vol. 37, pp. 101–28.

A. Ibrahim, F.A. Mohamed, and E.S. Lavernia: J. Mater. Sci., 1991, vol. 26, pp. 1137–56.

M.J. Koczak and M.K. Premkumar: J. Metall., 1993, vol. 45, pp. 44–48.

R. Asthana: J. Mat. Sci., 1998, vol. 33, pp. 1679–98.

M.K. Aghajanian, J.T. Burke, D.R. White, and A.S. Nagelberg: SAMPE Q, 1989, vol. 20 (4), pp. 43–46.

M.K. Aghajanian, M.A. Rocazella, J.T. Burke, and S.D. Keck: J. Mater. Sci., 1991, vol. 6, pp. 447–54.

A.W. Urquhart: Adv. Mater. Process, 1991, July, pp. 25–29.

A.W. Urquhart: Mater. Sci. Eng., 1991, vol. A144, pp. 75–82.

R.E. Everett and R.J. Arsenault: Metal Matrix Composites: Processing and interfaces, Academic Press, New York, NY, 1991, pp. 121–50.

M.K. Aghajanian, A.S. Nagelberg, and C.R. Kennedy: U.S. Patent 5,020,584.

K.B. Lee and H. Kwon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 3087–95.

K.B. Lee and H. Kwon: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2999–3007.

K.B. Lee, J.P. Ahn, and H. Kwon: Mater. Mater. Trans. A, 2001, vol. 32A, pp. 0000–00.

K.B. Lee, H.S. Sim, S.Y. Cho, and H. Kwon: Mater. Sci. Eng., 2001, vol. A302, pp. 227–34.

K.B. Lee, H.S. Sim, S.H. Kim, K.H. Han, and H. Kwon: J. Mater. Sci., 2001, vol. 36, pp. 3179–88.

B. Maruyama and W.H. Hunt, Jr.: JOM, 1999, vol. 51 (11), pp. 59–64.

S.I. Hong, and G.T. Gray III: Acta Metall. Mater., 1992, vol. 40, pp. 3299–3315.

M. Manoharan and J.J. Lewandowski: Acta Metall. Mater., 1990, vol. 38, pp. 489–96.

M. Manoharan and J.J. Lewandowski: Mater. Sci. Eng., 1992, vol. A150, pp. 179–86.

J.K. Shang and R.O. Ritchie: Acta Metall., 1989, vol. 37, pp. 2267–78.

N.V. Ravi Kumar and E.S. Dwarakadasa: Composites Part A, 2000, vol. 31, pp. 1139–45.

M.C. Chou and C.H. Chao: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2005–12.

M.D. Kulkami, P.S. Robi, R.C. Prasad, and P. Ramakrishnan: Scripta Metall. Mater., 1994, vol. 31, pp. 237–42.

W.M. Zhong, G. L’Espérance, and M. Suéry: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 2637–50.

W.M. Zhong, G. L’Espérance, and M. Suéry: Mater. Sci. Eng., 1996, vol. A93, pp. 93–103.

C.H. Jin: Master’s Thesis, Kookmin University, Seoul, 2001.

F.J. Humphreys, W.S. Miller, and M.R. Djazeb: Mater. Sci. Technol., 1990, vol. 6, pp. 157–66.

M. Ferry, P. Monroe, A. Crosky, and T. Chandra: Mater. Sci. Technol., 1992, vol. 8, pp. 43–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, K.B., Kwon, H. Strength of Al-Zn-Mg-Cu matrix composite reinforced with SiC particles. Metall Mater Trans A 33, 455–465 (2002). https://doi.org/10.1007/s11661-002-0106-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0106-5