Abstract

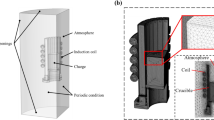

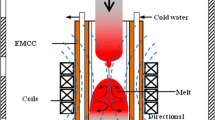

Based on the direct finite-difference method, a numerical model for simulating the temperature field in the charge during the induction skull melting (ISM) process has been developed in this article. The related factors, including water-cooling boundaries, the induction-heating electromagnetic stirring hump, and the power distribution in the charge, had been analyzed. The interfaces between the charge and crucible were treated as radiation boundaries before the charge was melted and as a combined boundary of radiation and conduction after the charge was melted. The free surface was treated as a radiation boundary. The relationship between the height of the electromagnetic stirring hump, charge weight, and melting power was derived based on the law of mass conservation. Based on the law of energy conservation, the distribution density of the induction current was attained. With the complied program, the temperature fields in the charge of Ti-47Ni-9Nb under different melting powers and/or charge weights were calculated. The results show that increasing the rate of the melting power has no influence on melt temperature. The ratio of melt weight to charge weight is determined by the melting power and charge weight. The melt temperature can be expressed as T=A 0+A 1×P+A 2×P 2, in which the coefficients A 0, A 1, and A 2 are cubic functions of the charge weight, and P is the melting power.

Similar content being viewed by others

References

C.L. Chu, B. Li, S.D. Wang, S.G. Zhang, X.X. Yang, and Z.D. Yin: Trans. Nonferrous Met. Soc. China, 1997, vol. 7 (4), pp. 84–87.

S.M. Green, D.M. Grant, and N.R. Kelly: Powder Metall., 1997, vol. 40 (1), pp. 43–47.

P. Filip and K. Mazanec: Scripta Metall. Mater., 1995, vol. 32 (9), pp. 1375–80.

W.S. Tang, J. Deng, and G.J. Yang: Acta Metall. Sinica, 1999, vol. 35 (s1), pp. 120–23.

H.B. Bomberger and F.H. Froes: JOM, 1984, vol. 36 (12), pp. 39–47.

J.W. Sears: JOM, 1990, vol. 42 (3), pp. 7–21.

K. Sakamoto, K. Yoshikawa, and T. Kusamichi: Iron Steel Inst. Jpn. Int., 1992, vol. 32 (5), pp. 616–24.

D.J. Chronister, S.W. Scott, D.R. Stickle, D. Eylon, and F.H. Froes: JOM, 1986, vol. 38 (9), pp. 51–54.

R. Scott: Proc. 1995 124th TMS Annual Meeting, Las Vegas, NV, Feb. 13–16 1995.

H.C. Yi and J.J. Moore: J. Mater. Sci., 1989 vol. 24 (10), pp. 449–55.

X.M. Zhang, W.H. Yin, and J.H. Guo: Powder Metall. Technol., 1995, vol. 13 (2), pp. 121–26.

J.J. Guo, Y.Q. Su, and J. Jia: Int. J. Cast Met. Res., 1999, vol. 12, pp. 35–40.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Su, Y., Liu, Y., Liu, G. et al. Molding of temperature field for the induction skull melting process of Ti-47Ni-9Nb. Metall Mater Trans A 32, 2895–2902 (2001). https://doi.org/10.1007/s11661-001-1040-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-1040-7